Composites are always used whenever the properties of the single material are insufficient relating to the application. Although there is a broad number of variations, metals are limited in strength, stiffness or wear resistance as an example. Combining them with ceramic components, their fields of application can be expanded and their long-term resistance extended.

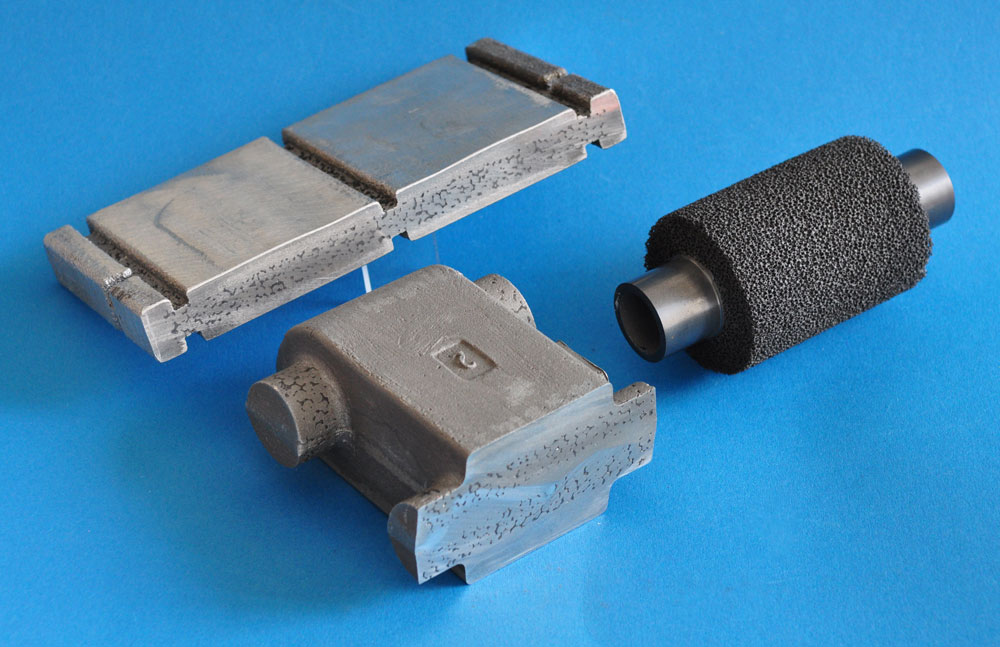

Porous inserts made of ceramics, so called preforms, are made for the reinforcement of metal components at specific positions with high stresses. Therewith, only specific parts of the component will be reinforced with ceramics, which guarantees a good machining and reduces the manufacturing costs.

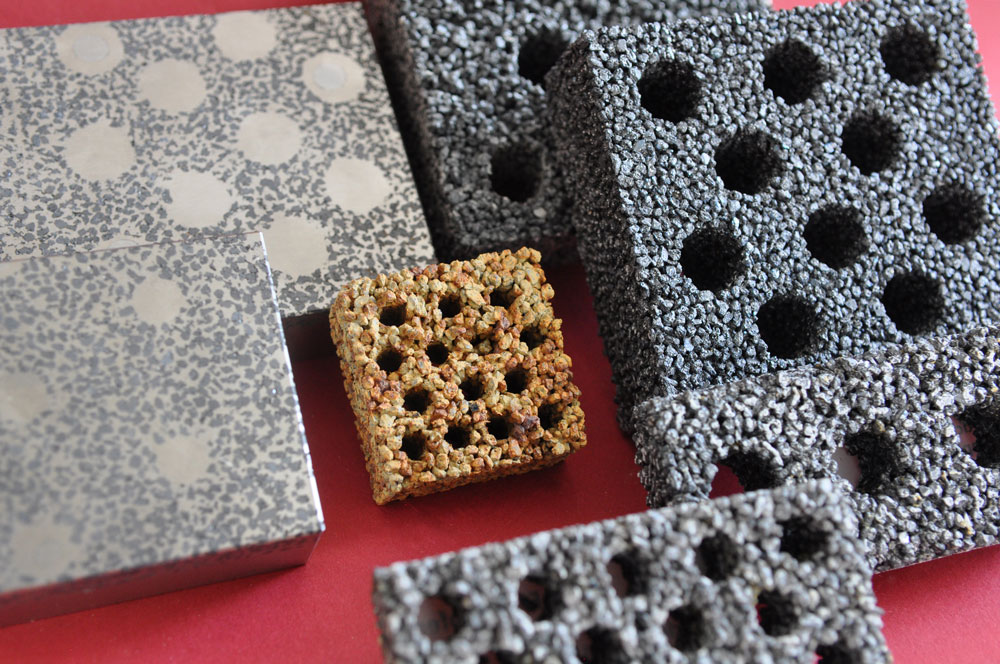

Fraunhofer IKTS develops and manufactures preforms made of coarse sintered particles or ceramic foams. Depending on the application, a wide range of already available ceramic materials can be selected or further developed. Additionally, the geometries of both kinds of preforms are highly variable so that very small pieces as well as extremely large sizes can be manufactured.

The sintered particle preforms are made of coarse particles and have comparably high ceramic amounts up to 50 % and more. Due to their structure, they are especially suitable for applications, which require high wear resistance and operating times. They can be casted with variable cast metals using gravity casting processes.

Foam preforms are a modified form of the classic ceramic foams which are used for the filtration and purification of metal melts. In contrast to the standard quality, the preforms have significantly higher ceramic contents of up to 30 % and a specific rough surface for a very good interlocking of preform and metal. These foam preforms are mainly used for the reinforcement of light metal alloys to achieve higher stiffness, for instance. Here, mainly pressure-die castings are used for infiltration. Alternatively, metal foams, such as steel, can be applied, which is also developed by Fraunhofer IKTS.

Most important for the properties of the metal-matrix composites is the contact area between metal and ceramic to achieve a very good bonding. It has to be adapted for every new material combination using special surface and material variations. Fraunhofer IKTS is not only a developing institution for ceramic preforms but has also established good cooperation with foundries. This allows the development of composites focused on application-oriented material combinations.

Services offered

- Development of ceramic and metal preforms made of foams

- Development of coarse particle preforms

- Development of composites in cooperation with foundries

- Characterization of composites

- Manufacturing of preform prototypes and series

Technical equipment

- Efficient technologies for the development and manufacturing of preforms made of ceramic and metal foams up to pilot-plant scale

- Proven process technology for preforms from miniature up to large dimensions

Examples and references

- Preforms for light metal composites with high stiffness for engine technologies

- Preforms for wear-resistant components for mineral processing technology and mining