Vertical-axis ultrasonic measurement system for characterizing slurries

Current research

In addition to being used for the non-destructive testing of solids, ultrasonic methods are becoming increasingly popular for the material characterization of liquids and slurries as well. In particular, ultrasonic spectroscopy, i.e. the evaluation of frequency-dependent parameters, has proven a very suitable method for characterizing dispersive materials. Unlike optical spectroscopy, it is not limited to translucent materials, which means that opaque and highly filled slurries can also be characterized.

Precise measurements of material characteristics

Fraunhofer IKTS has developed a flexible measurement system for an industrial project in order to evaluate slurries with high solid contents. These are used, for instance, in the production of batteries and need to be evaluated in terms of their composition and mechanical properties.

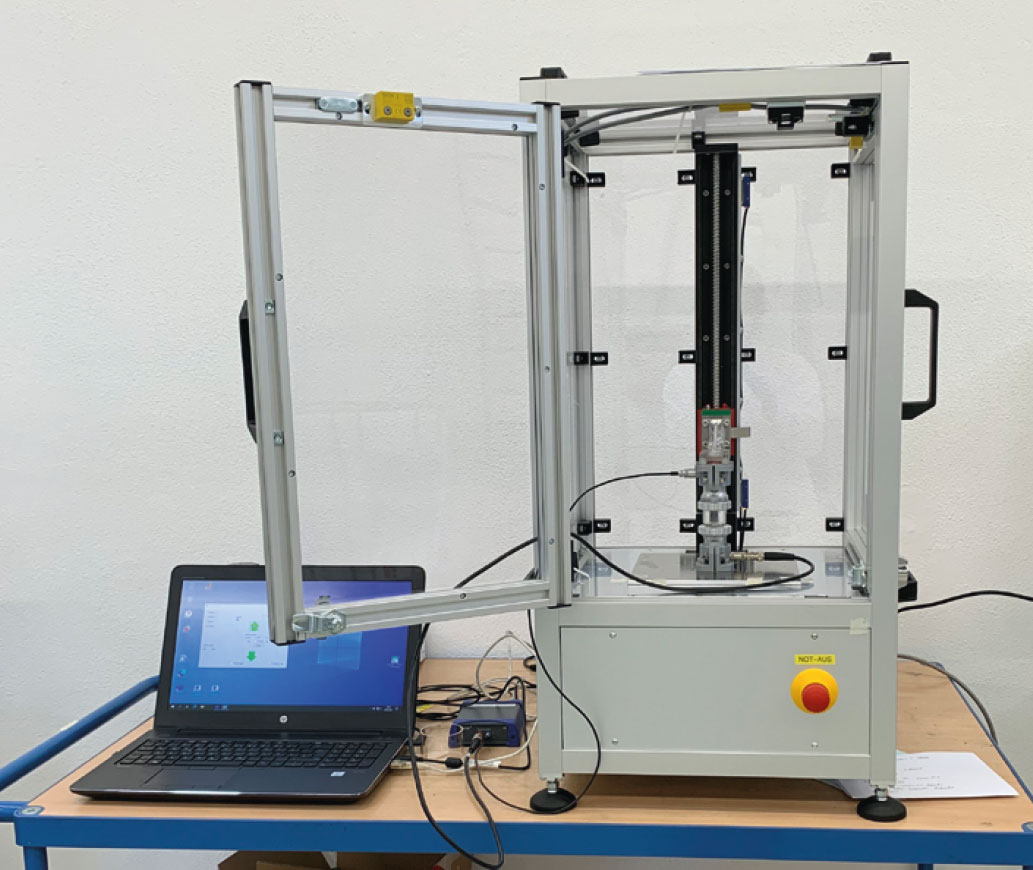

The vertical-axis system shown in the top figure achieves precise measurements with different test volumes. The system operates in transmission and reflection modes. One ultrasonic probe is fixed to an arm on the vertical axis, which can be moved with a step width of 0.1 mm and a maximum possible accuracy of 0.01 mm. This probe emits an ultrasonic wave that travels through the sample and is received by a second probe. Alternatively, the backscattered echo from the sample can be detected by the transmitter. The system consisting of axis and motor provides a maximum torque of 0.62 Nm. Therefore, it is capable of characterizing even highly viscous materials. The housing complies with the necessary measures for industrial safety and can be fitted with an exhaust system when working with outgassing or hazardous materials. Customized flexible adapters were developed for fastening the probes. They can be produced quickly and inexpensively through 3D printing, thus allowing for the use of different types of probes. A specially developed software controls the axis. For ultrasonic measurements, the system can be combined with the Fraunhofer IKTS PCUS® pro devices or with other commercially available systems.

Characterization of slurries in battery production

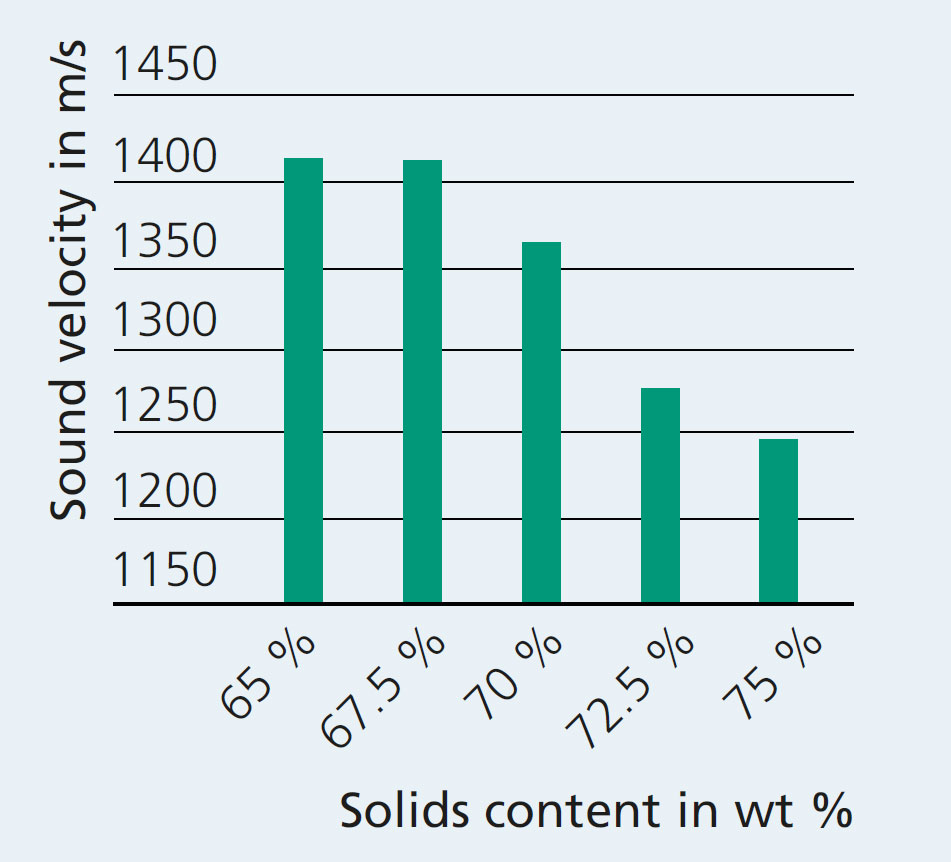

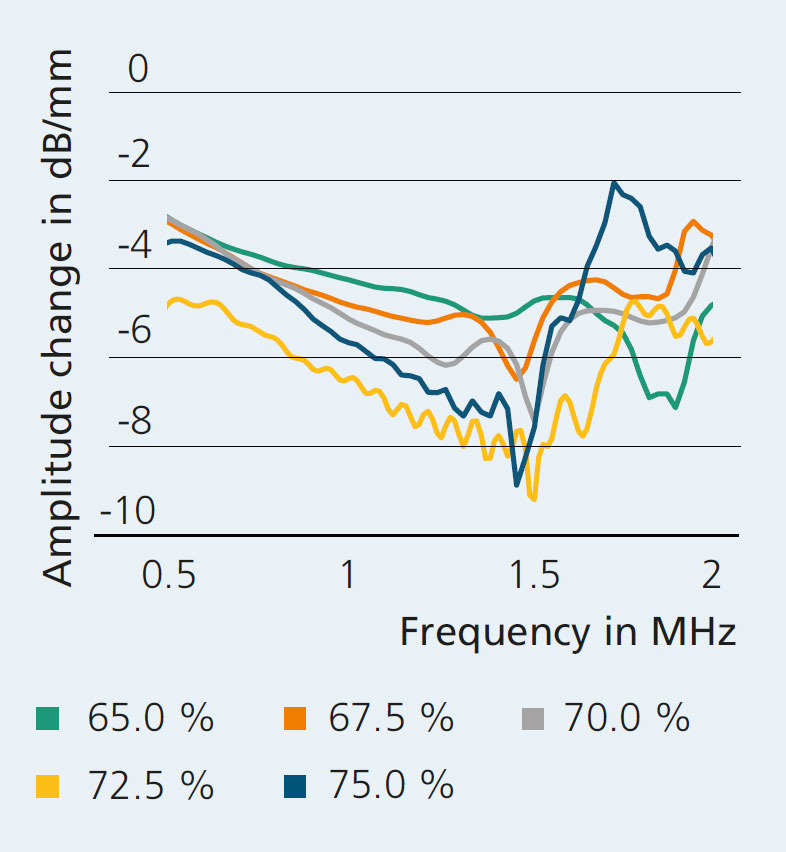

This system can measure frequency-dependent sound velocities and attenuation coefficients. From this, it is possible to derive the (visco-)elastic properties of the material. When slurry is characterized, effects such as scattering occur, providing the measured signals with additional information on the material state, for example on microstructure, particle size and concentration. By comparing several measurements at different thicknesses, influencing variables can be minimized, helping to achieve high reproducibility and reliability. The characterization of battery slurries revealed further influencing factors, for example service life and the mechanical pre-treatment of the samples. In the future, the measuring system will also be used for other material systems, such as printing pastes.