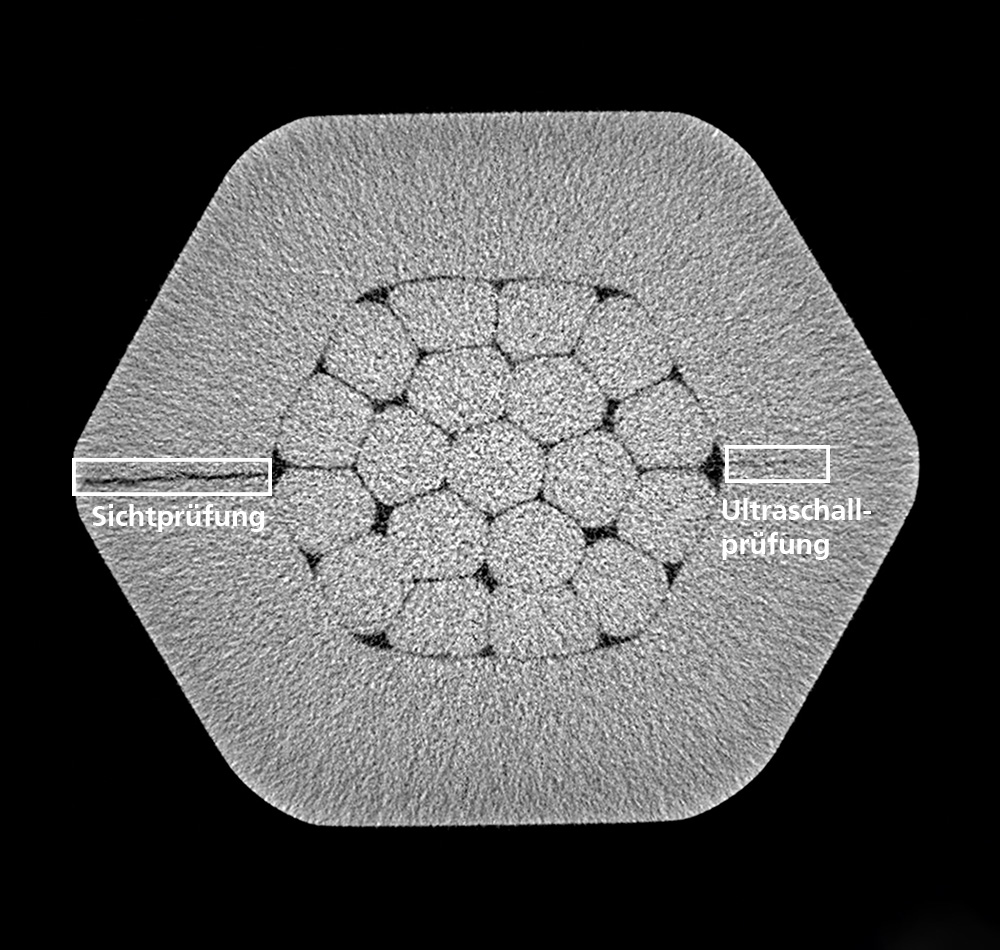

In electric rail transport, catenaries are mechanically and electrically connected to each other by means of tensile strength press connectors (PV) made of copper-containing alloys. Crack detection after assembly as well as during aging was previously only possible visually from the outside. Accordingly, a crack could not be detected as a potential connector failure until it had already grown outwards through the cross-section.

With an ultrasonic testing system for catenaries developed at Fraunhofer IKTS and successfully tested in the field, it is now possible for the first time to detect cracking already in the formation process. Using an inspection gripper adapted to the hexagonal cross-section of the press connector, six ultrasonic probes are pressed against the crimped surface. This allows the complete press connector to be tested without repositioning the gripper. The six probes emit the ultrasonic waves one after the other, clocked by a multiplexer. In the process, these enter the press connector at a precisely defined angle through an angled leading wedge. This directs the sound waves directly to the internal cracks and generates echo signals in reflection. These return to the probes via the reverse path and thus indicate the presence of cracks. During an inspection, potentially endangered press connectors can now be detected in good time and replaced accordingly.

Specifications of the ultrasonic testing system

- Mechanical test gripper for locking 6 probes on the press connector for 70 mm² or 50 mm² cross-sections

- Ultrasonic electronics PCUS® pro Single with MUX extension and outdoor USB connections (IP 65)

- Integrierter Hall-Sensor zur Schließüberwachung Integrated Hall sensor for closing monitoring

- Outdoor tablet, e. g. PANASONIC

- Hand-free operation thanks to RUXTON Gear Pack

- Ultrasonic software based on PCUS® pro Lab

- Tablet with simple touch user interface