Optoceramic components

Topic

View through a transparent Al2O3-disc / on the left part of the picture (thickness 1 mm) / right side without ceramic disc

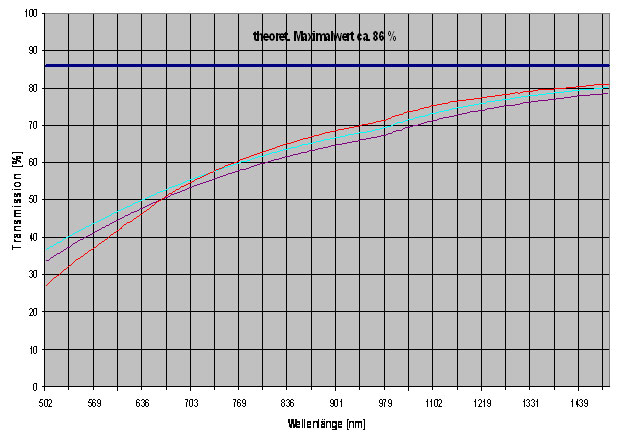

Spectrally transmission at Transparent discs (sub-µm Al2O3) compared with the theoretical maximum

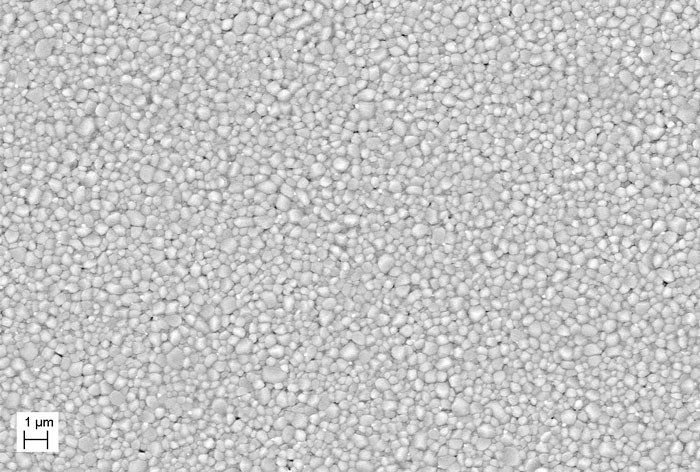

Structure of transparent ceramic / Al2O3 > 99,90% d50 = 0,35 µm / HV(0,1) = 3000 Transmission at lambda = 800 nm (Thickness 1 mm): 63 %

Recent developments at Powder manufactoring and Sintering processes make more interest for Optoceramics for optical applications because of here special combination of optical and mechanical properties. Advantageous are the spectrally transmissionen from UV to IR and the different refractive index compared to optical glass. This can enable new optical concepts.

Profile

- Oxide ceramic materials with high density, purity, strength and functional dopants for optical applications

- Materials based on Alumina (a-Al2O3), Spinell (MgO.Al2O3), Zirconia (ZrO2) und Yttria-Alumina-Garnet (3Y2O3.5Al2O3)

- Ceramic materials with homogeneous,poor in defects and superfine structure design using superfine and nanoscaled starting powder

- Optoceramic materials with a high level of transmission in UV-,VIS- und IR-range

- Development of industry-oriented manufacturing technologies with the inclusion of modern production technologies to assure custom-designed structur-property-relations of the polycristalline materials

Services offered

- Development of single- and multi-phase oxid ceramic components for special optical applications (mean system is Al2O3-ZrO2-MgO-Y2O3-SiO2)

- Manufacturing technologies to avoid flaws for advanced properties

- Uniaxial dry pressing for samples

- Slip casting of ceramic components with complex geometry

- Charakterization of custom-designed material spezifications

- Prototype - and small series manufacturing according customer specification

Technical equipment

- Ultra fine millling from sub-µm- to nm-range

- Water-based dispersing of ultra-fine powders

- Spray drying of fine-particle slurries

- Uniaxial dry pressing (mechanical and hydraulic)

- Thermal processes (reductive and oxidic)

- Finishing processes (precision grinding and lapping)

- Surface measurement TALYSURF (Taylor Hobson)

- Transmission Spectrometer SPECORD (Analytik Jena AG)