Defektfreies Fügen von Verbunden mit Transparentkeramik

Forschung aktuell

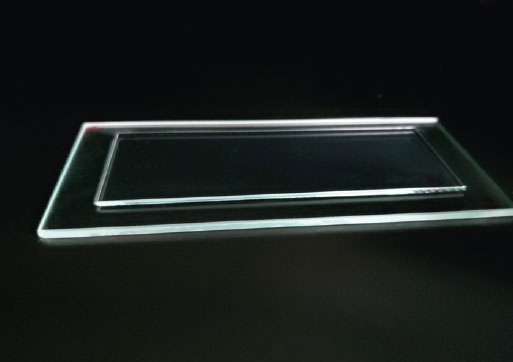

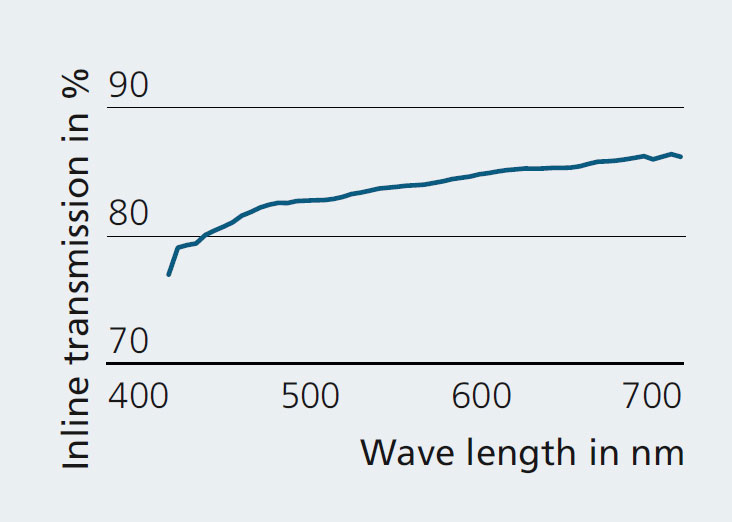

In the field of modern surface applications, transparent spinel ceramics represent a wear- and corrosion-resistant alternative to commercially available materials such as polycarbonate and hardened or unhardened glass. Even with their polycrystalline structure, they have a comparable optical transparency in the wavelength range of visible light. Various applications such as optical scanners, telephone displays or optical sensors require laminating transparent spinel ceramics with functional components in optical quality. For this purpose, Fraunhofer IKTS has developed technologies for laminating transparent ceramics with thicknesses from 0.2 to 5 mm with glass, such as borofloat glass, or plastics, such as PET or PVC, using acrylate and epoxy adhesives. To avoid dust inclusions, lamination takes place in partially enclosed glass boxes with a supply of filtered air with slight overpressure in a specially insulated clean room.

The technological process consists of the following steps: To clean and activate the surfaces to be joined, all components must be treated in an oxygen microwave plasma. Depending on the chemical stability of the materials, the plasma treatment is preceded by additional cleaning steps, such as treatment in an ultra-sonic water bath and with organic solvents.

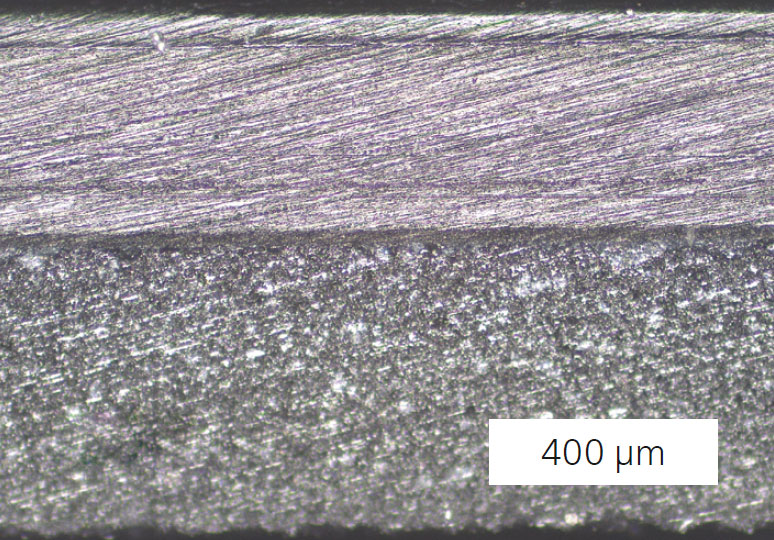

In the next process step, a dispenser will apply the adhesives. The researchers developed de-fined coating patterns, which are dependent on the size of the surface to be joined. They enable complete and bubble-free wetting without adhesive transfer to the edges of the laminate structure. Systematic investigations have shown that the lowest error rates and best reproducibility can be achieved with bonding layer thicknesses between 50 and 100 μm.

After applying the adhesive, the components have so far been assembled manually. This process step has proven to be very prone to uneven adhesive distribution and carries the risk of bubbles being trapped in the joining gap. For defect-free and reproducible lamination results, there are plans for the development of a plant concept for the mechanical lamination of components of different sizes and the construction of a laboratory system.

The final technological step includes the curing of the adhesive. If acrylate adhesive is used, this is done through irradiation with UV light. If two-component epoxy resins are used, especially when joining with plastics, curing at room temperature is preferable to thermal curing at 60–80 °C, so as to avoid distortion of the composite laminates.

The favorable mechanical properties of the composites, such as adhesive strength, tensile shear strength and transverse rupture strength, were shown through characterization in accordance with the relevant test standards.

The research and development work was carried out in cooperation with the Materials Engineering department at Ernst Abbe Hochschule Jena, University of Applied Sciences.