The only resurfacing prostheses available today are made of metal CoCrMo alloys. These cause metal abrasion, with particles and dissolved metal ions being detectable both in the surrounding tissue and in the blood. This may lead to metallosis disease, which causes irritation, infections, allergic reactions and pseudotumors. Fraunhofer IKTS is part of a collaborative research project, which aims to realize a metal-free ceramic surface replacement for the endoprosthetic reconstruction of the human hip joint. To that end, Fraunhofer IKTS has joined with medical technology manufacturer Mathys Orthopädie GmbH to develop constructive and manufacturing solutions for the fabrication of a femoral cap and a monolithic acetabulum made of ATZ dispersion ceramics (alumina-toughened zirconia).

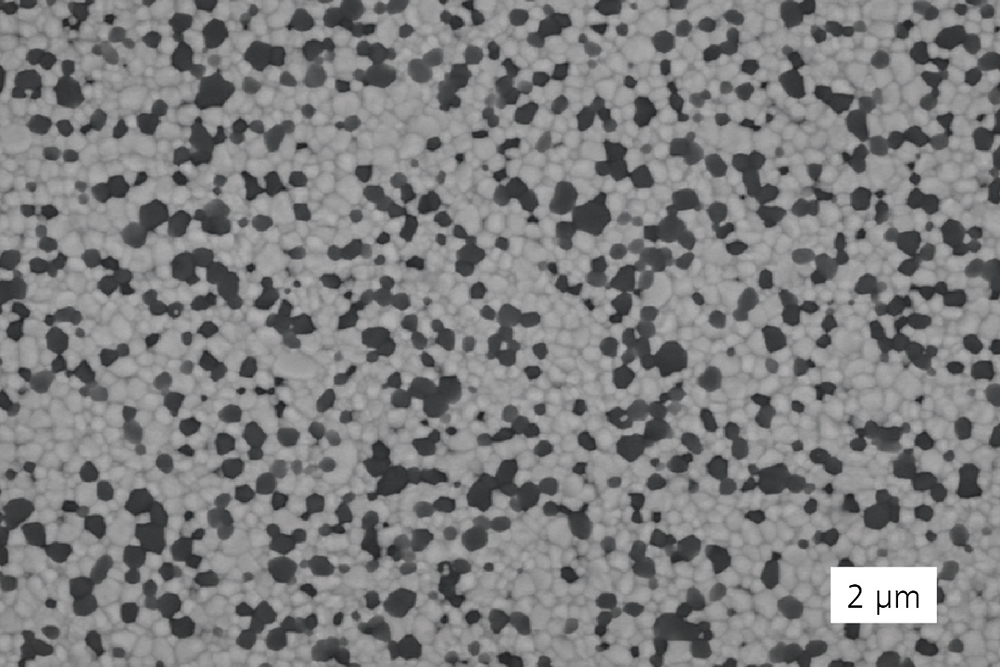

Fraunhofer IKTS uses a slip casting process to achieve the shape of the acetabulum. The surface of the ceramic component is structured during the shaping process, so that it does not need to be subsequently processed with subtractive or additive methods. The first half shells with structured surfaces have been produced and the molded ceramic surfaces have been characterized. Various alumina- and yttrium-stabilized zirconia powders from different price segments have been processed as part of the project. Figure 1 shows the structure of such ATZ dispersion ceramics.

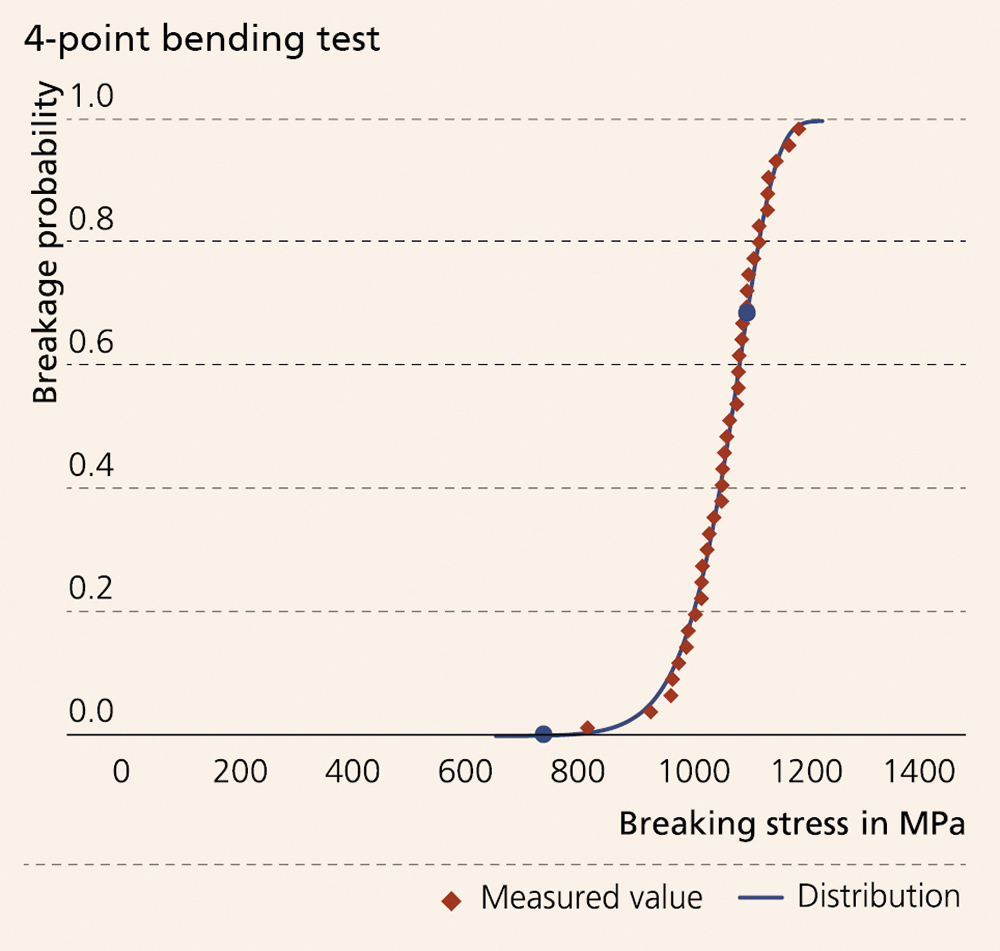

The mean grain size at a sintering and HIP temperature of 1450 °C for the light phase (TZ3Y) is at 350 nm and for the dark phase (alumina) at 300 nm. The four-point bending test (EN 843-1) determined that the Weibull parameters were promising: s0 = 1110 MPa and m = 18.5.

Strength distribution

In the further course of the project, investigations will be carried out to learn more about the component strengths of hip shell prototypes. As a result, surface replacement prostheses will be developed which offer a longer service life and are better tolerated by the patient.