Polymer-ceramic composites and their processing by thermo-set forming techniques

Topic

Fields of Activity

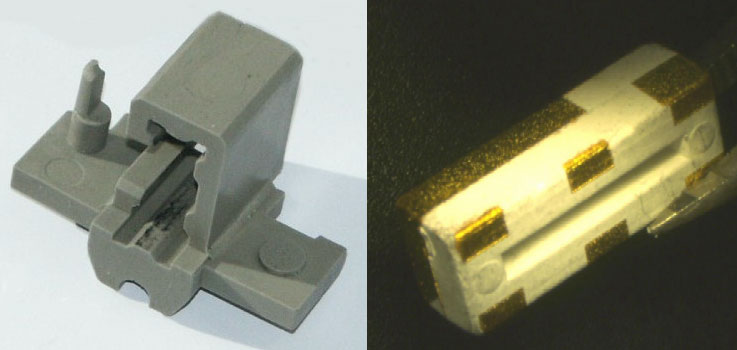

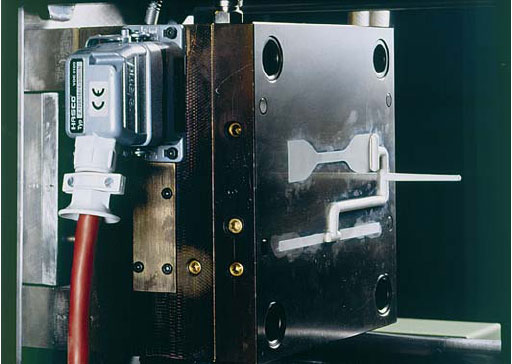

Polymer ceramic materials are inorganic-organic composites consisting of ceramic fillers and a matrix of organic polymers – particularly polysiloxanes . The formation of polymer ceramics is based on thermal curing of functionalized resins being able to form ceramic-like structures in the result of heat treatment above 200°C.Polymer-ceramics can be processed by a broad variety of plastic forming techniques like high pressure injection moulding or extrusion.Polymer-ceramic composites are characterized by high thermal stability (possible service temperatures above 600°C), low shrinkage, high stability of shape, and high dimensional accuracy. Relevant usage properties (e.g. electric al conductivity, thermal conductivity, dielectric al conductivity) and processing parameters can be adjusted by the choice of appropriate functional fillers, binder systems, and plasticizing additives.The application of polymer-ceramic materials could pay off if a cost efficient , easy processing of the material including plastic forming techniques in order to realize complex shaped parts are required and the thermal stability of standard materials like plastics does not suffice.Various electro-technical components subjected to heavy thermal load could be developed based on polymer-ceramic composites. The diversity of application of polymer-ceramics could also be demonstrated by the development of joining materials and foamed materials exhibiting high thermal stability and good thermal isolation capability.

Services offered

- Development of polymer-ceramic composites with optimized application properties (e.g. functionalized properties, high thermal stability, joining pastes, foamed materials)

- Development of components containing polymer-ceramic elements and their manufacturing technologies based on plastic forming techniques

- Manufacturing of application samples or small test series under industry-like conditions

- Material preparation and processing (granulates for injection moulding, reactive semi-finished parts)

- Plastic forming of thermo-plastic or thermo-set materials (injection moulding, extrusion, pressing)

Technical equipment

- Processing of base materials by mixing, rolling, and extrusion

- High pressure injection moulding

- Furnaces with controlled gas atmospheres

- Measuring mixer, rheometers, and injection moulding tool with measurement of inner pressure for the characterization of the flowability of high viscous and reactive materials and determination of control parameters of the injection moulding process