New excellence in machining hardened steel and heterogeneous cast iron

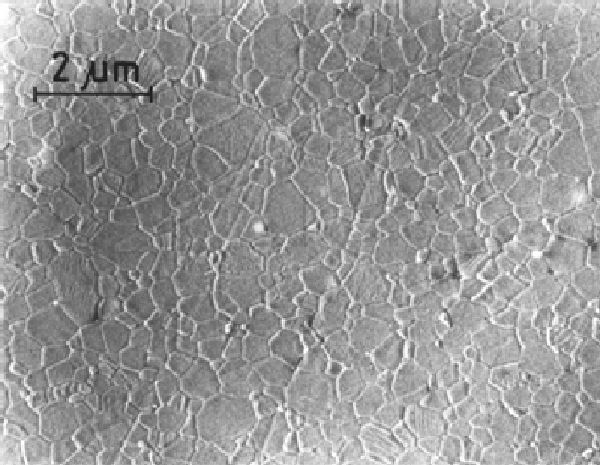

Ceramic processing that avoids defects gives high-strength, very hard wear resistant α-Al2O3-tools for extreme cutting operations at high velocities and even under interrupted conditions.

Advantages

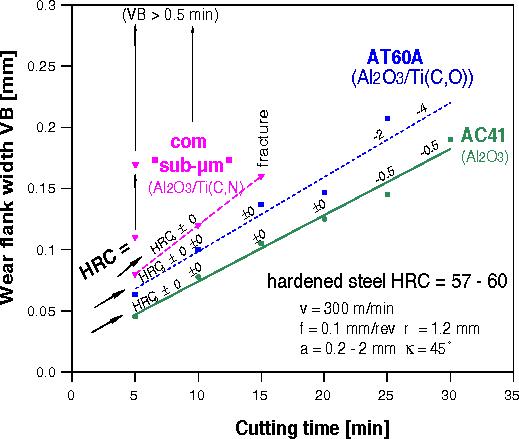

- High chemical and thermal stability of Al2O3 ceramics with sub-µm microstructure minimize the interaction with the machined materials, cutting forces, tool wear, cutting edge displacement and the roughness of the machined part up to high velocities (e.g. precision machining of hardened steel [hardness HRC=60] at * 300).

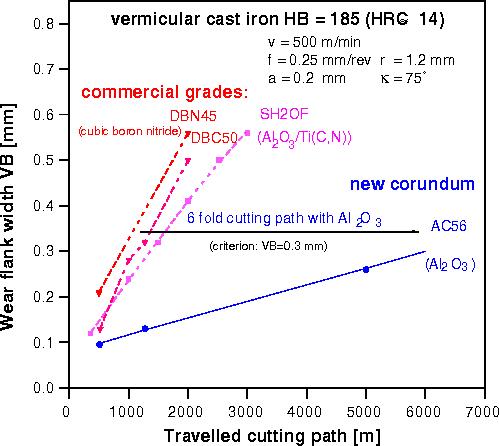

- Best machining of globular hard (chilled) cast iron (GGG) and of vermicular cast iron (GGV).

- Coarse machining of the rough outer shell of hardened steel shafts, even with interrupted cutting conditions.

- Preference compared with known cutting tools (e.g. Al2O3/ZrO2, Al2O3/carbide reinforcement, CBN) on cutting operations described above.

|

|

|

Products and services offered

- Development of technologies to manufacture submicrometer Al2O3 cutting tools, upscaling investigations

- Development of optimized materials for specific applications

- Application related cutting tests (turning, milling)