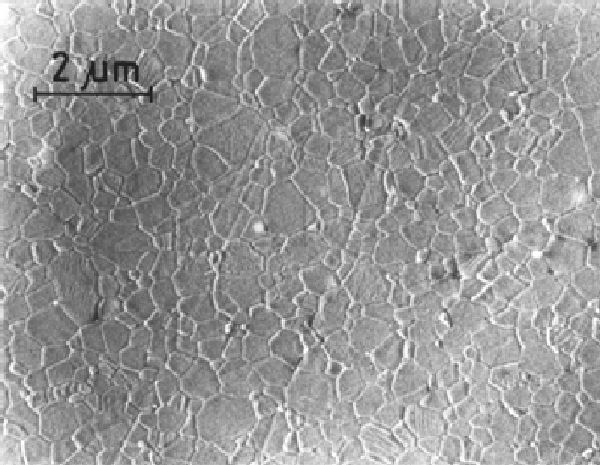

Submicrometer Al2O3 ceramic (average grain size 0.56 µm).

Higher hardness of sintered corundum by smaller grain size (realistic record requires measurement of macrohardness HV10 at 10 kg testing load).

![Improved ballistic strength by increased hardness of sub-micron sintered Al2O3 ceramics (depth-of-penetration test with steel backing [EMI Freiburg]; almost no influence of strength). balistschutz3](/en/departments/structural_ceramics/nonoxide_ceramics/materials_synthesis_development/ballist_sintercorund/jcr:content/contentPar/sectioncomponent/sectionParsys/textblockwithpics/imageComponent3/image.img.jpg/1565084255769/balistschutz3-tcm185-62638.jpg)

Improved ballistic strength by increased hardness of sub-micron sintered Al2O3 ceramics (depth-of-penetration test with steel backing [EMI Freiburg]; almost no influence of strength).

Improved protective efficiency by high hardness of submicrometer ceramics

Ceramic processing that avoids defects gives high-strength and very hard α-Al2O3 protective tiles of low weight.

Advantages

Very high hardness of sintered dense Al2O3 ceramic with sub-µm microstructure:

- Improved protective performance at low weight due to the correlation of high hardness and increasing mass efficiency

- To be manufactured by simple, pressureless sintering at low temperatures

Products and services offered

- Development of technologies to manufacture submicrometer Al2O3 protective materials, upscaling investigations

- Development of optimized materials for specific applications

- Application related investigations of the ballistic protective performance in cooperation with the Fraunhofer Institute for High-Speed Dynamics (Ernst-Mach-Institut) Freiburg i.Br.