Wear resistent transparent corundum balls.

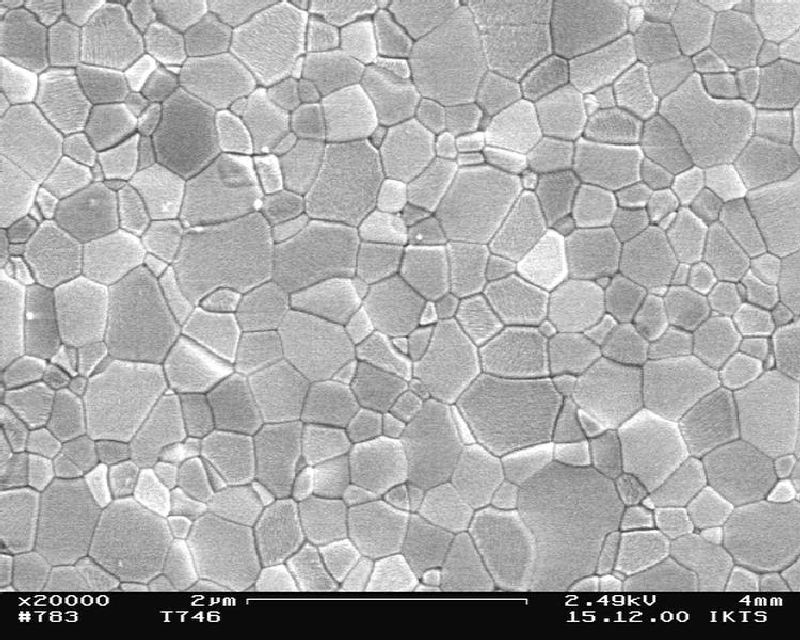

Highly pure microstructure of sintered α-Al2O3 grinding balls. Average grain size 0.41 µm at relative density > 99.9 %.

Vickers hardness HV10 = 2090 ± 50

Perfect sub-µm micostructures reduce the wear of grinding balls in volume, particle size, and impurity content

Known grinding balls with low and sub-µm wear consist, e.g. of ZrO2 (detrimental in Al2O3 substrates for microelectronics or in alumina with high permeability for microwaves), balls of 85 % Al2O3 introduce silica impurities. Commercial high-purity Al2O3 grinding balls exhibit increased and coarser wear. The corundum balls developed here by IKTS Dresden avoid these disadvantages and enable highly pure ceramic processing for special use.

Advantages

- Highest purity > 99.9 % α-Al2O3.

- Minimum wear (1/4 of the typical wear of 85 % Al2O3 balls) due to sub-µm grain size < 0.5 µm at high relative density > 99.9%.

- High hardness HV10 > 2000.

- Small average particle size of wear (0.6 µm).

- Use in fast attrition mills enabled by high specific fracture stress (750 – 1000 MPa in compression).

Services offered

- License on know how. Upscaling. Contributions to the development of an industrial production of new grinding balls.

- Supply of new wear resistant corundum balls.

- Investigations of the performance in technical applications.

| Grade of grinding balls | Wear rate* [%/h] |

| New product from IKTS | 0.025 |

| commercial 85% Al2O3 | 0.09 |

| commercial ZrO2(TZ-3Y) | 0.02 |

* Wear of new sub-µm alumina grinding balls in an attrition mill (water, 1000 rev/min) in comparison with commercial grades.