Contributing to energy generation

Increasing the efficiency of future power stations run at temperatures > 1400 °C

Specific challenge

- High creep resistance at high temperature, and

- sufficient "damage tolerance" (stress relaxation) underconditions of thermal shock

associated by:

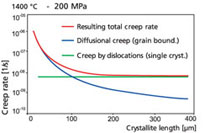

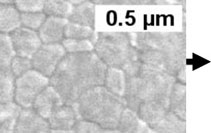

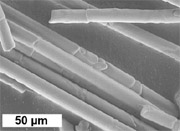

1. Conversion of commercial fibers with sub-µm microstructure into highly creep resistant components by re-crystallization

|

|

|

| Microstructures of Al2O3 fibers: original (commercial) state and after re-crystallization at 1750°C/Ar. | ||

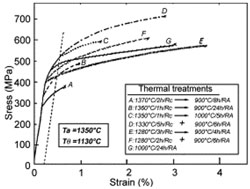

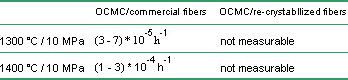

Creep results

(composites with mullite or Al2O3 matrix; fiber content ~ 40 vol-%):

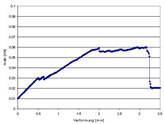

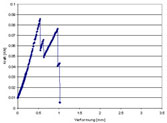

2. Tailoring damage tolerance by tuning the fiber/matrix interface strength from "week" to "strong"

|

|

|

| Mullite matrix sintered 1400 °C (P=35 %). | Al2O3/mullite matrix sintered 1600 °C (P=22 %). | reference: TiAl - applicable up to ~ 800...900 °C only |

Ease of OCMC manufacture

| (a) | Using commercial ("affordable“) bundles of easily processable polycrystalline fibers with subsequent re-crystallization, or |

| (b) | Separate fiber re-crystallization (cooperation: ISC Wuerzburg) followed by shaping of composites |

| --> | Creep resistance similar single-crystal fibers without associated technological restrictions |

Tube demonstrator, Al2O3, Ø 40 mm x 70 mm.