Improved quality by new ceramic processing

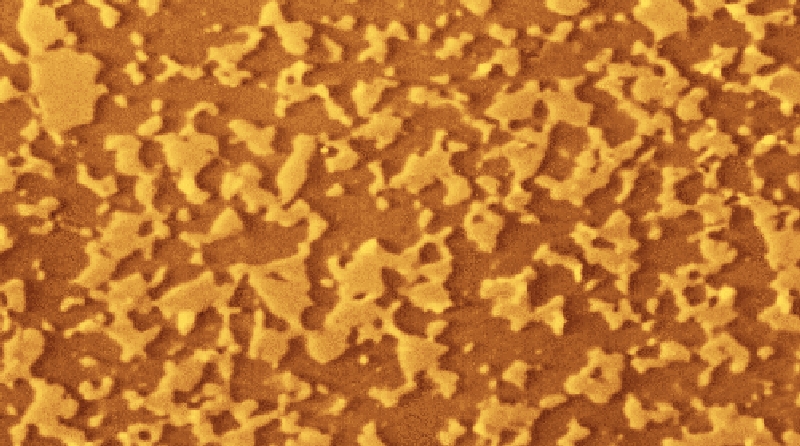

Pressureless sintered or hot-isostatically pressed alumina ceramics with high contents of TiC or Ti(C,O,N) are characterized by a microstructure where the grain boundaries are free of any amorphous films. Adjusted compositions and technological approaches are developed to meet special requirements in technical applications and are used to produce individual prototypes and small series.

Applications

- Sliding head substrates in data storage systems

- Equipment for sinter forging (e.g. glass lenses with high quality of surfaces)

- High precision wear-resistant parts (e.g. chucks for the automatic change of tools)

- Cutting tool inserts

- Substitution of Al2O3 to enable advantageous electroerosive processing of parts

Advantages

An important merit of the developed technology is the possibility to achieve improved properties without expensive hot pressing. The advantages of the material:

- Compared with commercial pure alumina ceramics are an increased hardness and strength

- Compared with carbide-reinforced zirconia it is its the high oxidation resistance. The production of parts with complex geometries is enabled by the easy electroerosive processability of the electrically conducting material

| Properties | Typical data | ||

| sintered | sintered + HIP | ||

| Density | g/cm³ | 4.29 - 4.34 | |

| Grain size | µm | ≥ 0,5 | |

| Sourface roughness Ra (after polishing) | nm | 5 - 7 | |

| Young´s modulus GPa | GPa | 360 | 390 |

| Bending strength | MPa | 600 - 700 | 800 - 900 |

| Facture toughness Kic | MPa m1/2 | 5 - 6 | |

| Vickers hardness HV 10 | 1900 - 2100 | 2100 - 2300 | |

| Electrical resistance | m Ω cm | 0,7 | |

| Thermal conductivity | W/mK | 21 | |