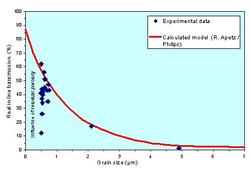

High transmission of unscattered light ("clear" appearance) of highly dense Al2O3 with sub-µm grain sizes at 640 nm wave length.

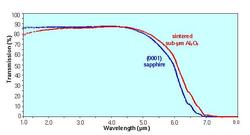

Same infrared transmission of sintered sub-µm Al2O3 as sapphire in the important 3-5 µm range.

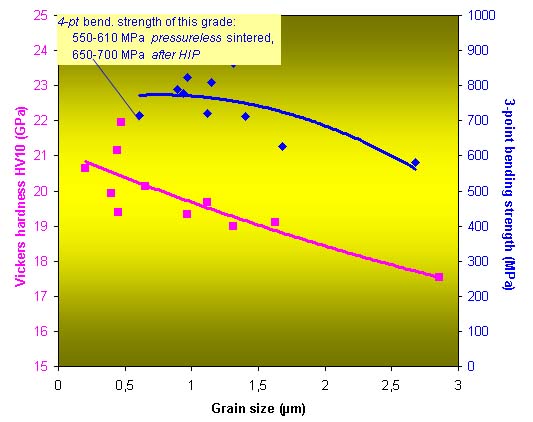

Reduced grain sizes of thermally and chemically stable α-Al2O3 (corundum) ceramics associate transparency with highest strength and hardness.

Sub-µm and nano-technologies for transparent components exhibiting highest strength, hardness and wear resistance together with an extreme thermal and chemical stability

Known "transparent" alumina ceramics exhibit low mechanical parameters and a low in-line transmission of unscattered light (< 15 %) because of coarse micro-structures (> 20 µm); in fact, they are optical not clear and rather translucent than transparent. The new sub-µm corundum ceramics (α-Al2O3, Fig. 1) avoids these shortcomings and can be manufactured with very complex shapes.

Advantages

- In-line transmission (wave length = 640 nm, aperture = 0.57 °) > 50 % at thickness 0.8 mm (Fig. 1)

- Same high infrared transmission as sapphire in the 3-5 µm range

- Extremely high strength (600-850 MPa), hardness (Fig. 3), scratch and wear resistance

- High chemical stability in acids, bases, and agressive gases

- Flexible shaping by casting (discs, tiles, complex hollow shapes); technology to be used also for other materials

Products and services offered

- Development of high-strength transparent ceramics, e.g. on the basis of corundum (α-Al2O3) with sub-µm/ nano microstructures

- Alternative developments with commercial or with nanoscale raw materials

- Technological investigations for upscaling supporting the development of new products; screening of raw materials and shaping approaches

- Investigations of the technical performance in various applications