New excellence in quality, availability and price by advanced syntheses

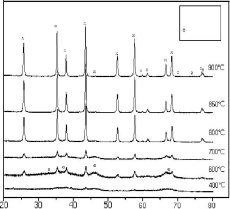

Associated with an adjusted use of precursors and seeding approaches, a special temperatur/time regime of the controlled hydrolysis enables the direct formation of gamma-Al2O3 from a quasiamorphous intermediate at 400-600°C and, finally, a transformation to corundum completed at low temperatures > 750°C.

Advantages

- Use of common, inexpensive raw materials (e.g. Al-nitrate), processes that can be run automatically

- Options: aqueous/inorganic and alcoholic/organic;

- Batch sizes large for subsequent technological development

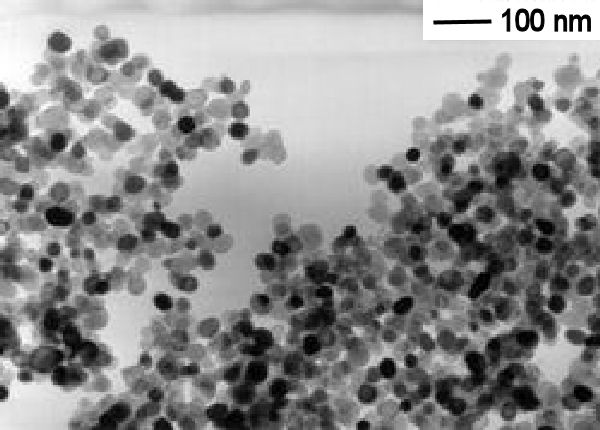

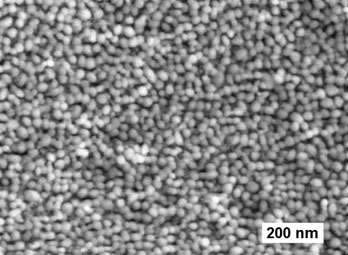

- Transformation to corundum at low temperature of about 800°C provides redispersible nanopowders

- Average size of redispersed calcined and ground particles >25 nm

Products and services offered

- Development of syntheses for nanocorundum with requested properties

- Upscaling investigations

- Developments for the processing of nanocorundum to produce

- porous coatings (membranes) and compacts

- dense and porous coatings on metallic substrates

- dense sintered compacts; options for sol/gel or powder technological approaches