Functionalized transparent yttrium-aluminum-granat ceramics YAG

Current research

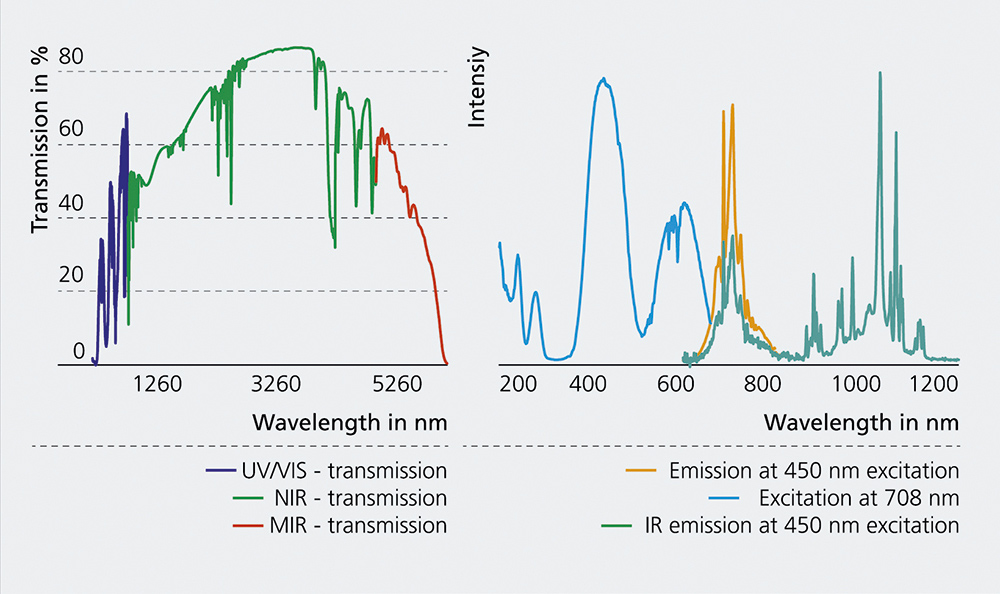

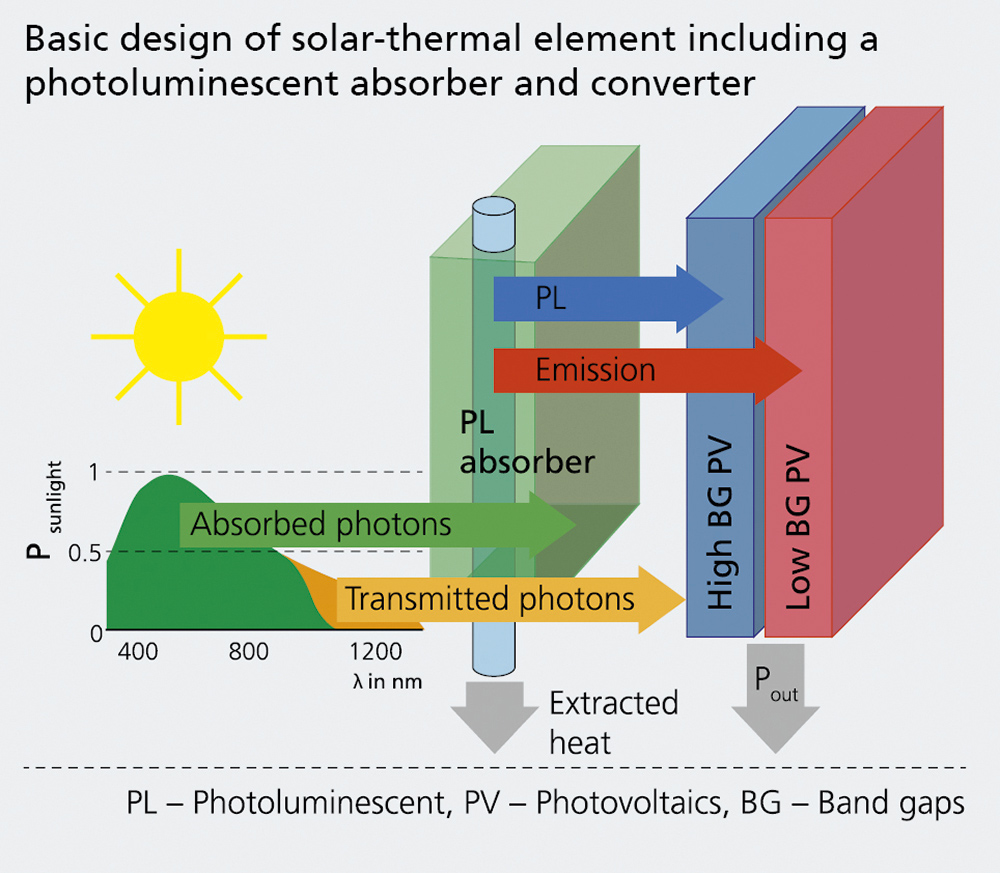

Over several decades, doped YAG ceramics have established themselves as important components in light engineering, laser technology, optoelectronics and also as gemstones. Cerium-doped YAG in crystalline form, for instance, is used as fluorescent substance in LEDs for lighting. YAG single crystals doped with neodymium or ytterbium have enabled the development of high-energy solid-state lasers for material processing, medical applications and measurement technology. Additional doping with chromium makes it possible to use YAG ceramics as absorber/converter panels in solar technology, utilizing the broad light spectrum of the sun (“Concentrated Solar Power Concept”) [1]. YAG single crystal growth using the Czochralski process is very expensive. The range of geometric dimensions and shapes of the parts is limited, as is the amount of dopants. Scientists at Fraunhofer IKTS have now managed to manufacture transparent doped YAG ceramics, adding to the manufacture of spinel MgAl2O4, cubic ZrO2 and MgO. The defect-free shaping technologies used for this manufacture allow many variations in terms of shape, size and number of monolithic ceramic components. In addition, the type and concentration of doping elements can be selected as needed for the functionality of each application. In cooperation with Technion in Haifa (Israel), the researchers produced triple-doped (Cr, Yb and Nd) absorber/ converter plates, 80 x 80 mm in size with a thickness of 3 mm (Figure 1). In a solar-power plant, the YAG ceramics are used to absorb sunlight and thermal radiation is transported away through a suitable medium (e.g. fused salt). Short-wave parts are converted to defined wavelengths, which can in turn be transformed into electricity by solar cells placed behind the absorbing ceramic plates (see working principle in graphic). Transparent CrNdYb:YAG ceramics enable precise and highly efficient conversion (Figure 2) in particular at high temperatures around 600 °C.

Literature

[1] S. Haviv u. a., OSA Technical Digest, Optical Society of America, 2019, paper jsiii_1_5].