Material weathering under real conditions in the marine environment

Current research

Ceramic components

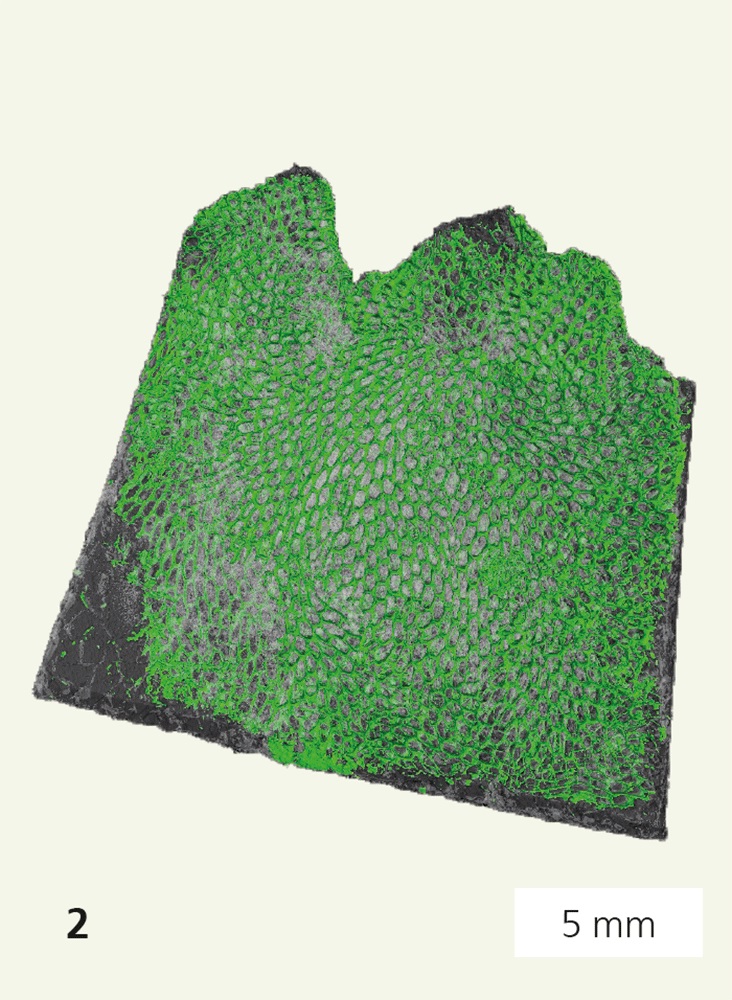

Antifouling coatings that reduce the growth of marine organisms on offshore wind turbines, anti-corrosive coatings for ship hulls, transparent ceramics for sensors in the sea – the advantages of ceramic components come to the fore under the harsh conditions of marine environments. The development of such materials must be accompanied by tests not only of their functionality but also of their durability under the conditions of use. Appropriate test setups in the laboratory, such as the salt spray test, are available for this purpose but they always represent only part of the real exposure. In real environments, the conditions are much more complex: Materials dissolved in water cause a chemical interaction while abrasive particles, such as sand, cause mechanical erosion. Finally, organisms present in marine environments can accumulate and cause biofouling.

With the aim of being able to carry out tests under real conditions

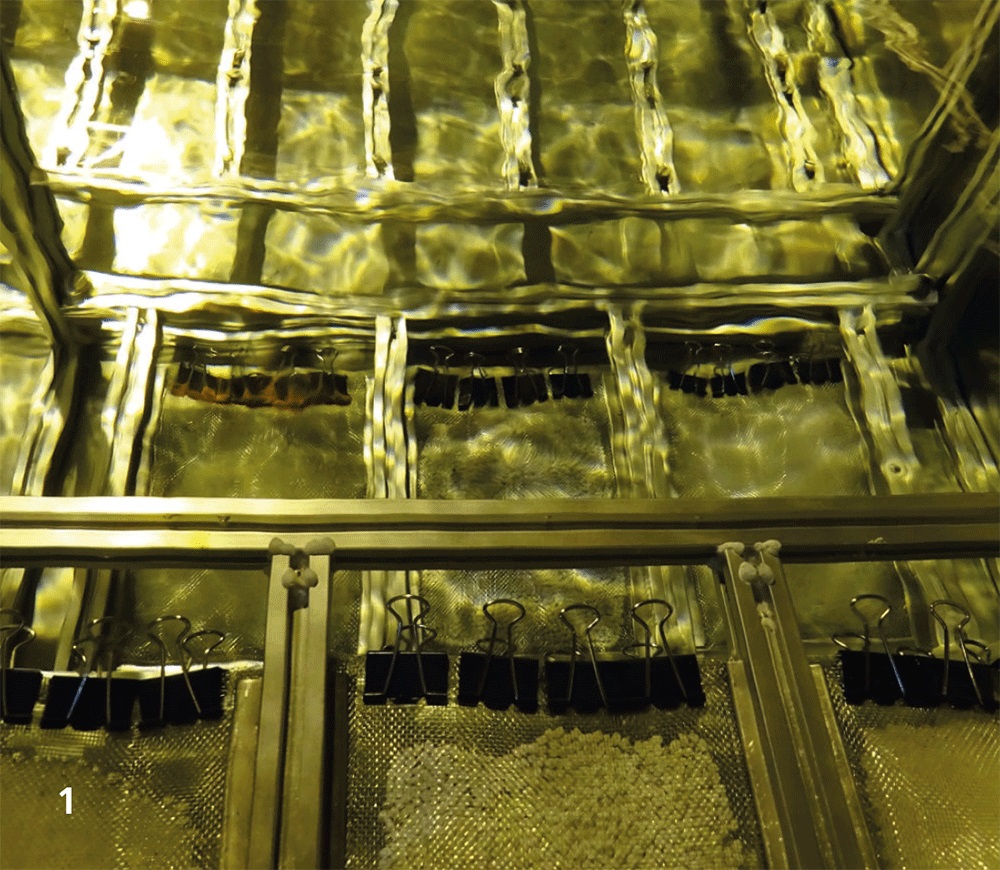

in the future, Fraunhofer IKTS is partnering with three other Fraunhofer institutes in the establishment of the “Smart Ocean Technologies” (SOT) research group in Rostock. The characterization of components of various geometries under real conditions can be realized from the laboratory to deployment in mesocosms which are permanently flowed through and monitored (Figure 1) or in an artificial reef in the Baltic Sea (Figure 3). The components and coatings are analyzed in detail regarding functionality and damage. Additionally, the leaching of substances is considered, thus creating the basis for an ecotoxicological risk assessment of the components.

From polymers to microplastic

While ceramic materials are deliberately introduced into the environment on an application-related basis, plastics enter the oceans unintentionally and can cause considerable damage there. Weathering processes and fragmentation lead to the formation of microplastics; additives can be leached out. The development of new polymers (including biodegradable ones) and the use of more effective additives require efficient testing for environmentally relevant side effects in the event of improper use before they are placed on the market. The required analysis is adapted to the specific test and considers both the surface properties of the component/plastic (microscopy, chemical composition, functional groups, charge, etc.) and the properties of the surrounding water (ion concentrations, DOC, etc.). Being able to take this holistic view into account as early as in the development of new materials is an added value for the users resulting from the work in the SOT.