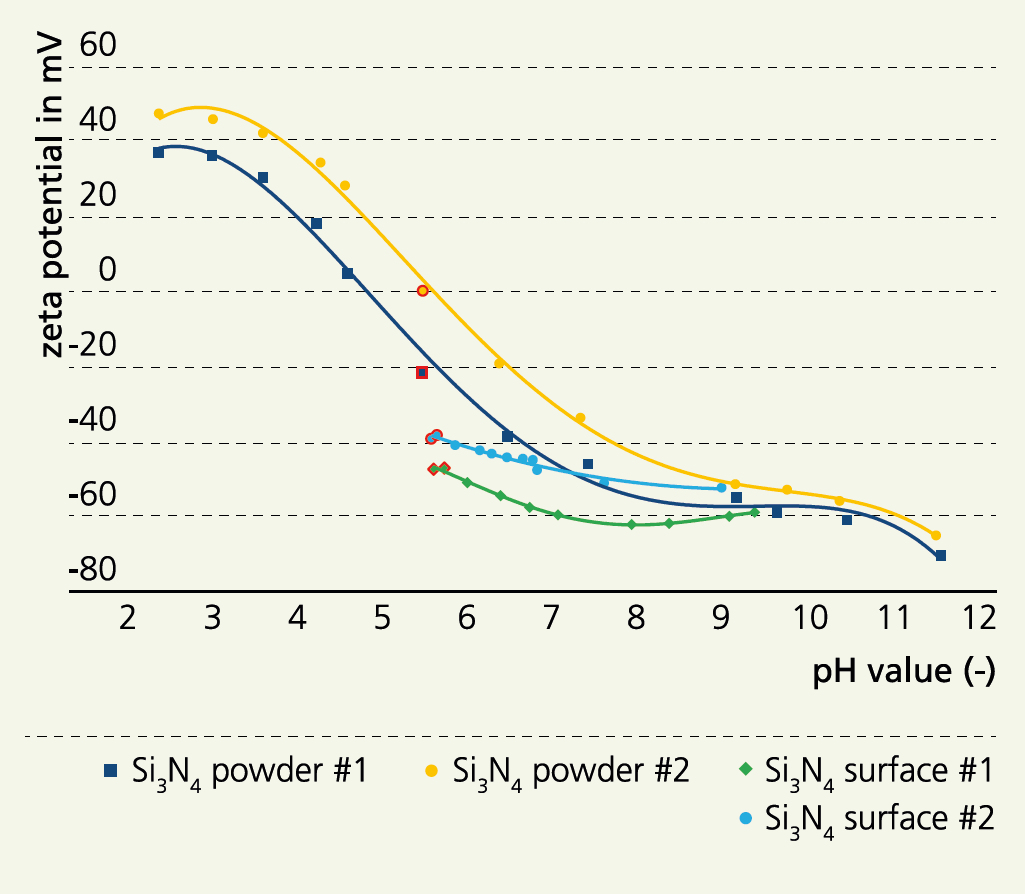

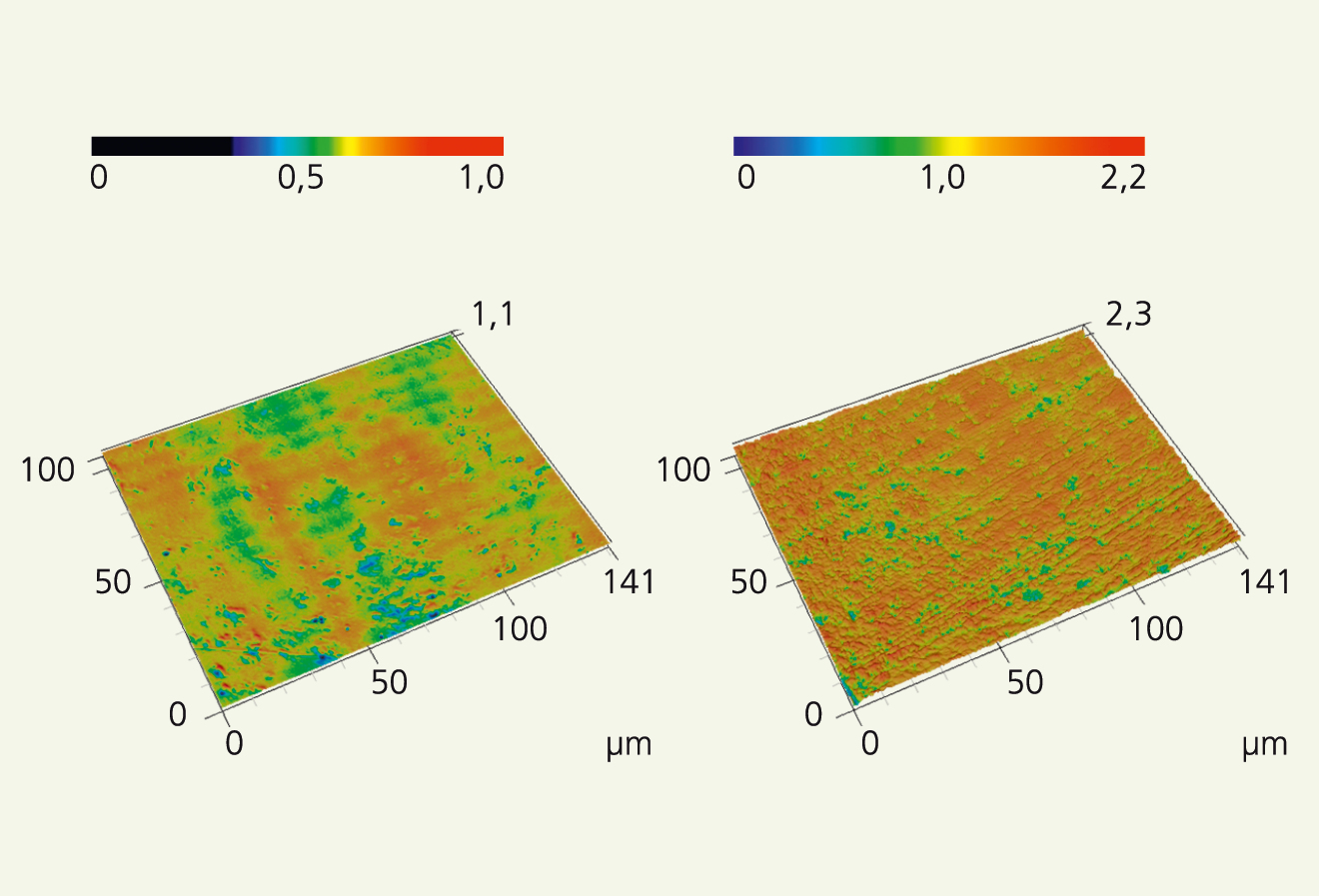

The behavior of components with ceramic surfaces is determined significantly by the structure and reactivity of the material. Such components are used in seals, bearings, fittings, as well as in medical and biological applications. A precise knowledge of material properties and behavior can help users analyze damage cases or further develop components in a targeted manner. Fraunhofer IKTS offers a wide range of methods for the surface characterization of ceramic components: Using confocal laser scanning microscopes, it is possible to determine the topography of ceramic surfaces with high-resolution – even on samples with preferred orientation (Figure 1). Additionally, atomic force microscopy (AFM) and nanoindenter methods are able to determine local elastic, electrical, dielectric and thermal properties. The chemical or phase composition of the component surface is analyzed using elemental or phase analysis. In order to understand tribological and biological processes, it is important to have knowledge of the interaction between surfaces and their surrounding media. Surface characterization by contact angle measurements is suitable for the quantification of the wettability of surfaces (i.e. hydrophilic/hydrophobic behavior). The surface charge can be determined by current potential measurements, giving insight into the chemical composition, especially the oxide formation, of whole component areas, for example of Si3N4- or SiC-components. The thicker the oxide layer in particle and component surfaces, the more the isoelectric point shifts to low pH ranges (Figure 2). Locally, oxide layer thicknesses on metals or non-oxides (thickness from a few nm to 100 nm) can be determined non-destructively using a thin-film tool in a scanning electron microscope. Likewise, the kinetics of the adsorption of organic materials, such as proteins on ceramic component surfaces or plastics, can be detected at IKTS by means of flow potential measurements. This analytical procedure provides valuable insights into the use of ceramics in medical technology, e.g. as bone substitute material. This analytical technique may also be applied in technical applications (e.g. electro-corrosion). The effect of chemical, thermal or mechanical functionalization or modifications on the properties of the surfaces can thus be reproducibly quantified.

Services offered

Analytical assessment of component surfaces intended for applications in

- Machinery and vehicle construction

- Medical technology

- Power engineering