Carbon membranes as separation technology for H2/natural gas mixtures

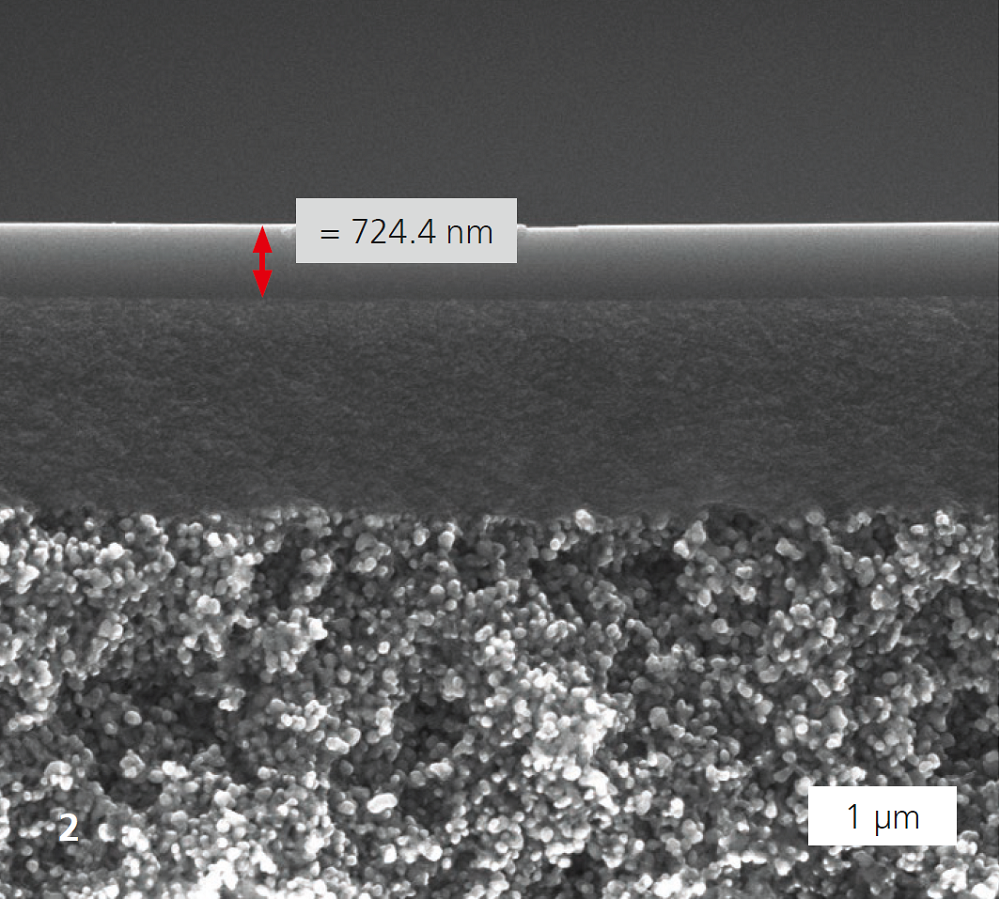

A main issue in achieving the switch from fossil fuels to renewable energies is the limited availability of renewable electricity due to its dependency on the weather. This challenge has led to numerous concepts aimed at converting power via power-to-gas technologies. Yet, none of the innovative technological approaches has so far passed the threshold of economic efficiency. One reason for this is the absence of a distribution grid. The project HYPOS (Hydrogen Power Storage & Solutions East Germany) aims to connect the chemical power grid, the natural gas grid and the electrical grids in East Germany to provide cost-efficient “green“ hydrogen. It has been the general consensus that no separate infrastructure for the storage and distribution of hydrogen will be established in Germany for the foreseeable future. Therefore, one will need to make use of the existing natural gas grid for the production and storage of hydrogen. However, for certain applications such as the use as fuel, the concentration of hydrogen in the natural gas grid must not exceed a certain threshold. To still be able to use that infrastructure, separating both components (hydrogen and natural gas) before redelivery would be an option: shared storage, separate use. The separation of both components can be realized efficiently by using carbon-based membranes developed at Fraunhofer IKTS in collaboration with project partner DBI-GUT GmbH. The basis for the synthesis of carbon membranes is a suitable precursor. The precursor is applied on an asymmetric porous, ceramic substrate in single-channel geometry. In a next step, the precursor is converted to carbon species with defined properties during a thermal treatment process. The layer thickness of carbon membranes is typically between 250 nm and 1 μm depending on the synthesis procedure and is characterized by an excellent separation behavior of H2/CH4, with ideal permselectivities of 300. The best membranes were able to concentrate 5 vol % hydrogen in the feed up to 80 vol % in the permeate. In a second separation step, more than 90 vol % hydrogen can be reached in the permeate. Additionally, it has been experimentally proven that the small amounts of water and hydrogen sulfide in the natural gas do not have any significant influence on the separation performance of the membrane. In the research project, carbon membranes were successfully scaled to industry-relevant 600 mm long 19-channel tube substrates.

We would like to thank the German Federal Ministry of Education and Research BMBF for their financial support (FKZ: 03ZZ0706A).