Advanced ceramics are versatile due to their crystal structure and the resulting properties such as high wear resistance, compressive strength, hardness and corrosion resistance. However, some potential applications are limited by their low thermal and electrical conductivity. In contrast, carbon nanotubes (CNTs) are characterized by their extreme tensile strength, high Young's modulus as well as high thermal (600 to 6000 W/mK) and electrical conductivity (106 to 107 S/cm). The aim of the BMBF-funded "NatKeKo" project is to combine the advantageous properties of both material classes in CNT ceramic composites. These are characterized by high thermal and electrical conductivity and could be used in rolling bearings and heating elements.

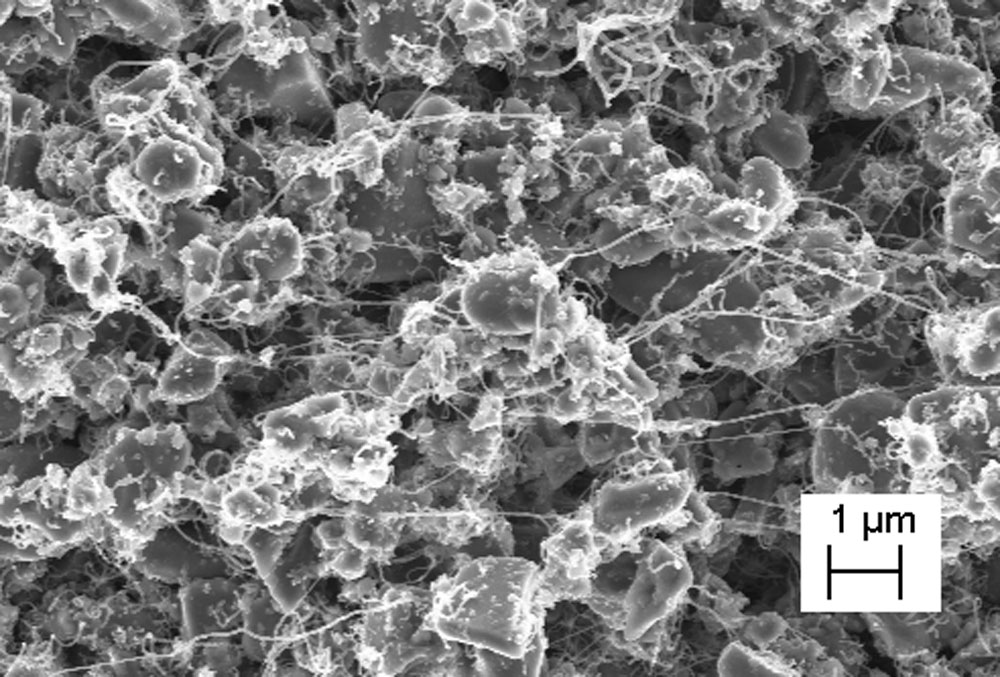

Using a wet chemical preparation route, defined concentrations of catalyst particles are applied to the different oxide and non-oxide powders (Al2O3, ZrO2 and Si3N4) and then a CVD process supports the growth of CNTs in a rotary tube furnace (batch sizes from 200 to 900 g). Homogeneous CNT growth on the ceramic particles is achieved by continuous agitation of the powder bed during the CVD process.

We are gratefully acknowledged to the German Federal Ministry of Education and Research (BMBF) for funding the project "NatKeKo - Tailor-made high-performance components made of carbon nanotube ceramic composites" (funding reference: 03XP0205E).