Production of high-performance CNT-ceramic composites

Current research

Enhancing high-performance ceramics with CNTs

High-performance ceramics are very versatile thanks to their high wear resistance, compressive strength, hardness and corrosion resistance. Nevertheless, where good thermal and electric conductivity is required, their fields of application are limited.

The combination of carbon nano tubes (CNTs) with ceramic powders, on the other hand, is exceptionally well suited for tackling this drawback of ceramic components. CNTs are characterized by extreme tensile strength (30–100 GPa), a high Young’s modulus (1–1.2 TPa) and high thermal (2000–6000 W/mK) and electric conductivities (106–107 S/m).

CNT-ceramic composites

The state of the art for manufacturing CNTceramic composites involves mixing ceramic powders with CNTs, followed by sintering. During powder mixing, however, the CNTs are prone to agglomeration, shortening and even decomposition.

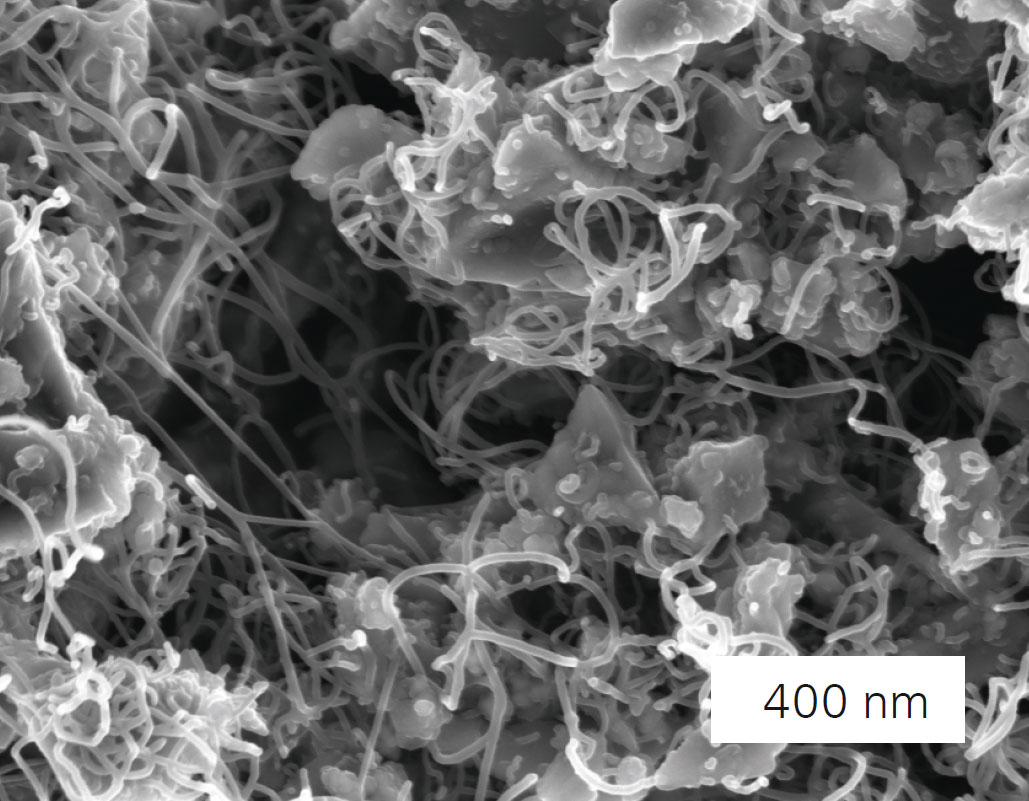

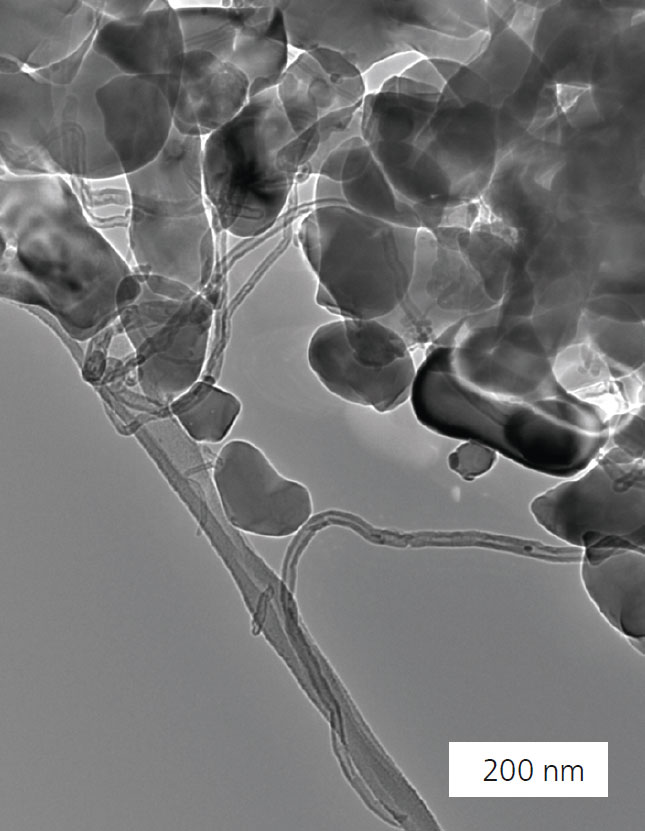

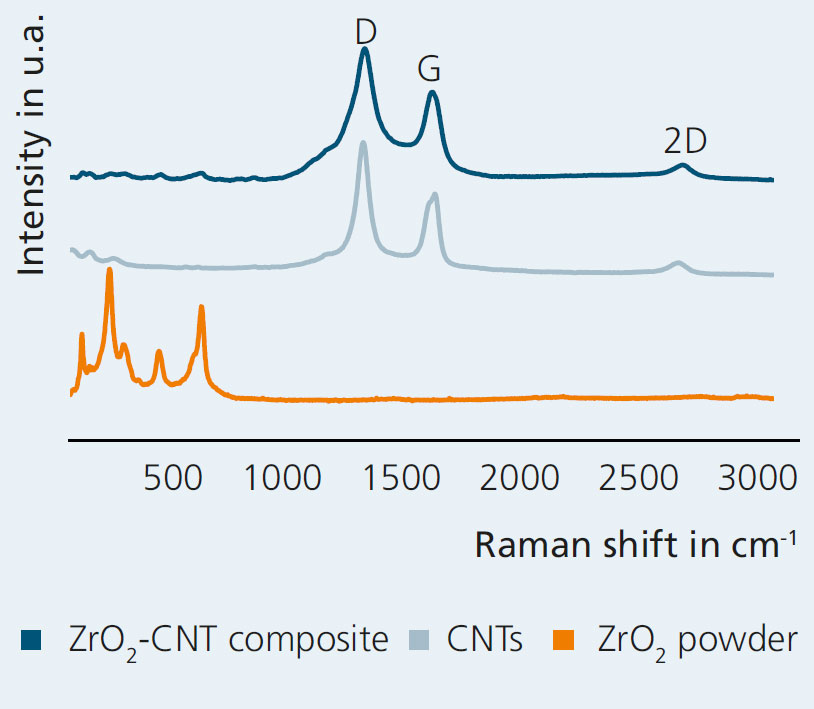

A Fraunhofer patented process allows covering oxidic and non-oxidic primary ceramic particles (Al2O3, ZrO2 and Si3N4) with deagglomerated CNTs. Defined concentrations of catalyst particles are deposited on the ceramic particles by a wet-chemical route. Subsequently, a chemical-vapor deposition process leads to the growth of the CNTs, starting from the catalyst particles. This leads to a very homogeneous distribution of the CNTs in the final CNT-ceramic composite.

Such high-performance composites are ideal for use in ceramic heating elements, conductive thread guides and low-wear rolling bearings.

Services offered

- Supply of ceramic powders functionalized with CNTs

- Shaping and sintering of ceramic powders functionalized with CNTs

- Comprehensive characterization of CNTceramic composites

We are grateful for the financial support (FKZ: 03XP0205E) of the German Federal Ministry of Education and Research (BMBF).

Supported by