Due to its temperature and pressure stability in combination with chemical resistance, carbon is interesting as a membrane material for tasks in gas separation, pervaporation, vapor permeation and liquid filtration.

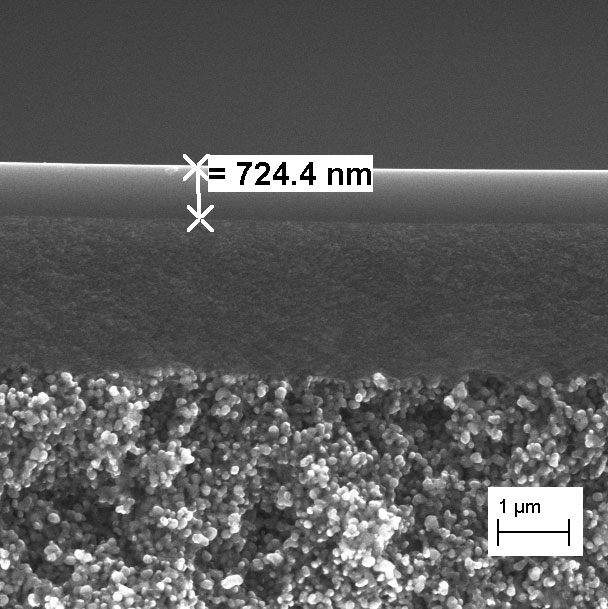

The gas transport through membranes is strongly dependent on material structure, pore size and thickness of the membrane layer. Therefore, carbon membranes are divided into two types: the molecular sieving carbon membrane (MSCM) and the adsorption-selective carbon membrane (ASCM). Molecular sieving carbon membranes allow the separation of gas mixtures due to different molecule sizes, such as for the selective separation of hydrogen from natural gas (H2/CH4). Adsorption-selective carbon membranes, on the other hand, allow the separation of gas mixtures with similar molecule sizes due to different adsorption behavior and different diffusion rates. They are used, for example, in biogas treatment for CO2/CH4 separation.

Services offered

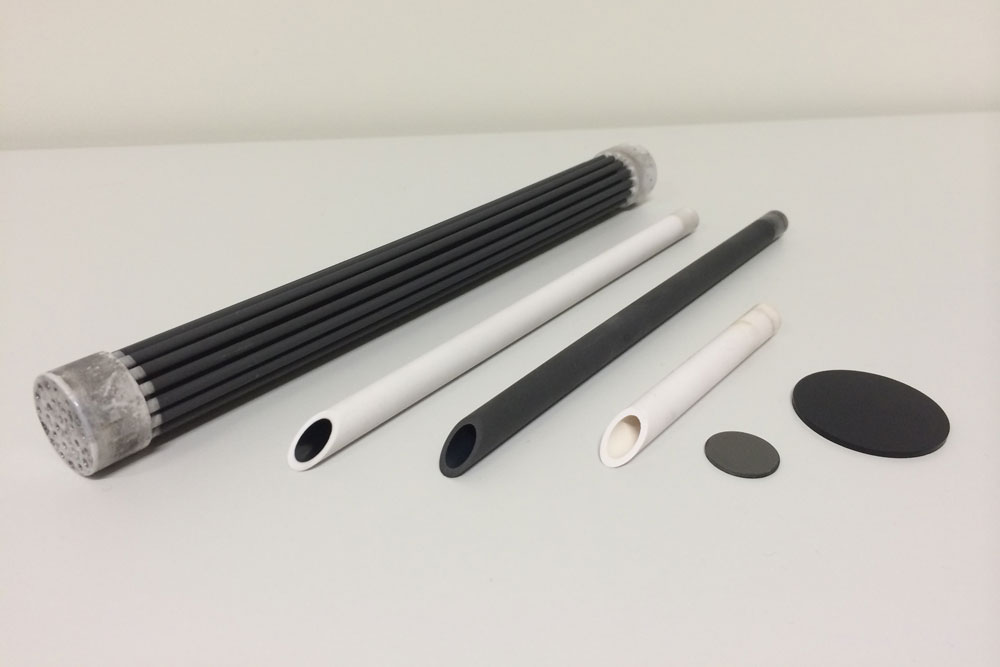

- Prototype production of asymmetrically structured carbon membranes on planar substrates and tube geometries (single channel and multi-channel) with a length of up to 0.5 m

- Development of carbon membranes for customer-specific tasks in gas separation, pervaporation, vapor permeation and liquid filtration

- Membrane preparation on ceramic substrates of own production as well as on customer substrates

- Scale-up of the membrane preparation including prototype production up to a length of 1.2 m