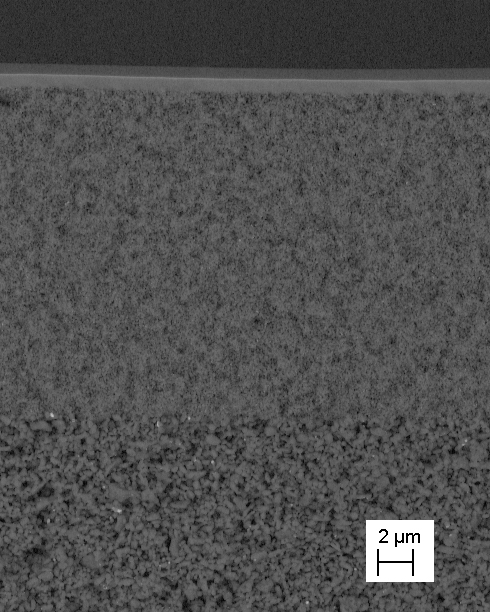

SEM image of the fracture surface of a PDC membrane based on SiC.

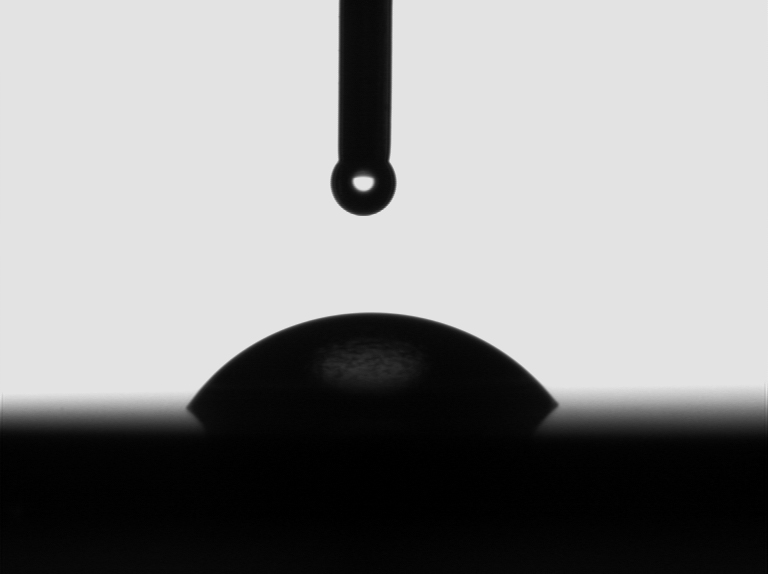

Microscopic image of a contact angle measurement to characterize the surface properties of a PDC membrane.

Glovebox for the manufacture of PDC membranes.

Polymer-derived ceramics (PDC) are suitable for selective gas separation at high temperatures, such as in power engineering and the chemical industry. The PDC membranes developed at Fraunhofer IKTS are based on silicon oxycarbide (SiOC), silicon carbonitride (SiCN) or silicon carbide (SiC) and show a particularly high temperature resistance. They offer an attractive combination of physical and chemical properties and a high mechanical hardness. By targeted optimization of synthesis routes, thin PDC membranes with molecular sieving properties, e.g. for the separation of hydrogen from gas mixtures, can be produced for high-temperature applications.

Services offered

- Development and synthesis of novel precursors for PDC membranes for customized high-temperature applications

- Optimization of the manufacturing process (coating, cross-linking, pyrolysis) for the deposition of coatings on different, possibly customer-specific substrates

- Characterization of porous PDC membranes by single and mixed gas permeance measurement as well as determination of pore size distribution by permporosimetry

- Customized separation tests

- Implementation of stability tests