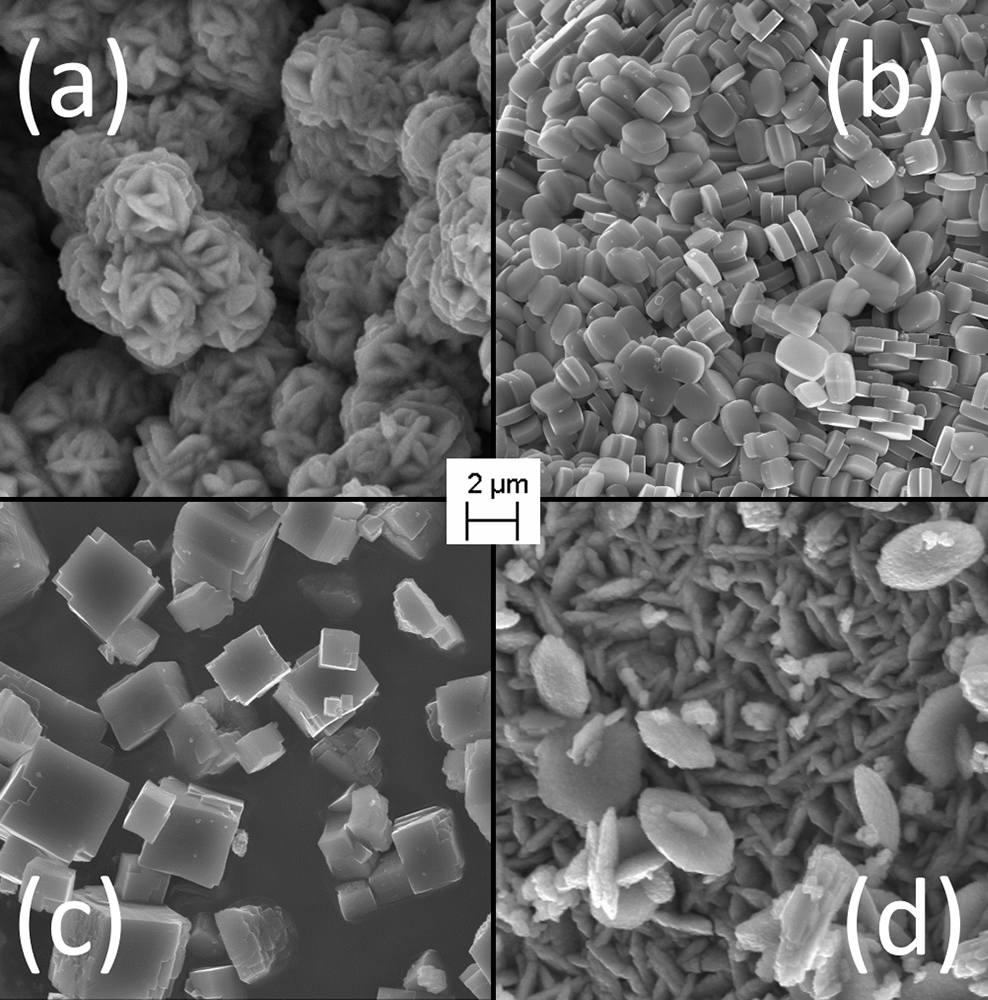

SEM images of synthesized zeolites: (a) faujasite, (b) ZSM-5, (c) SAPO-34 and (d) chabazite.

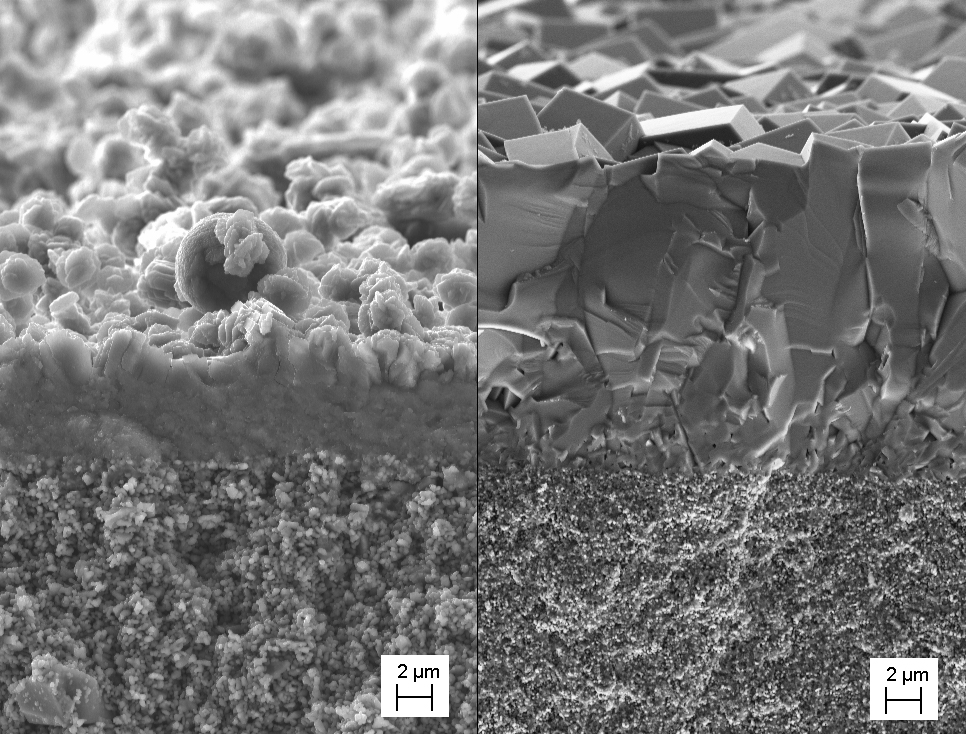

SEM image of the fracture surface of a chabasite zeolite membrane with an average layer thickness of 5 µm (left) and a SAPO-34 zeolite membrane with an average layer thickness of 18 µm (right).

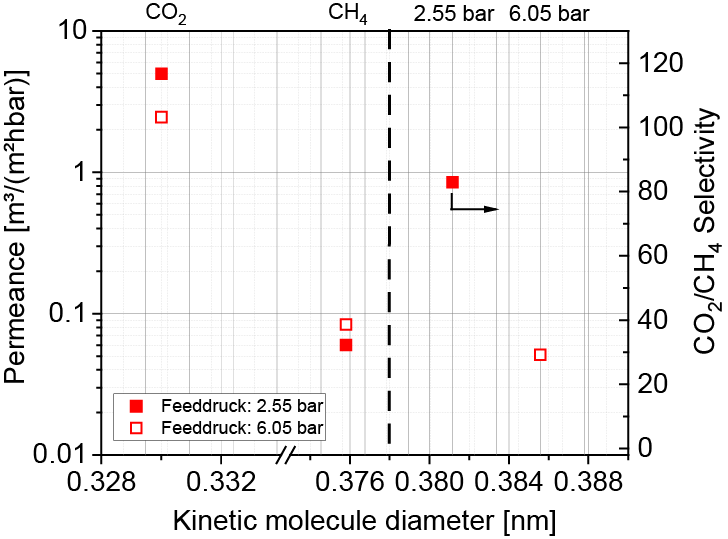

Mixture gas measurement on a SAPO-34 membrane for the separation of CO2/CH4. CO2 concentrations in the permeate of 93.5 % at 2.55 bar and of 94.5 % at 6.05 bar could be achieved.

At Fraunhofer IKTS zeolites are synthesized and characterized in powder form or as layers for use as membranes. Zeolite membranes can be used, for example, for energy and resource-efficient gas separation. The size of the gas molecules is below 1 nm, which places special demands on the membrane layer. It should be free of defects and have a high permeance combined with high permselectivity. The separation of the components can be achieved by molecular sieving and/or adsorption effects. In particular the high specific surface area also makes zeolites attractive for use in catalysis processes or in heat storage systems.

Services offered

- Synthesis of zeolite materials using conventional methods or microwave technology

- Characterization of zeolite materials (IR and Raman spectroscopy, microscopy, thermal analysis, N2 sorption)

- Physical and chemical functionalization of zeolites

- Coating of ceramic substrates with zeolite membranes

- Concept development for scaling and plant design

- Membrane characterization regarding gas separation (single and mixed gas measurements), pervaporation, vapor permeation and pore size determination

- Research and development of solutions for customer-specific separation tasks