Initial situation and motivation

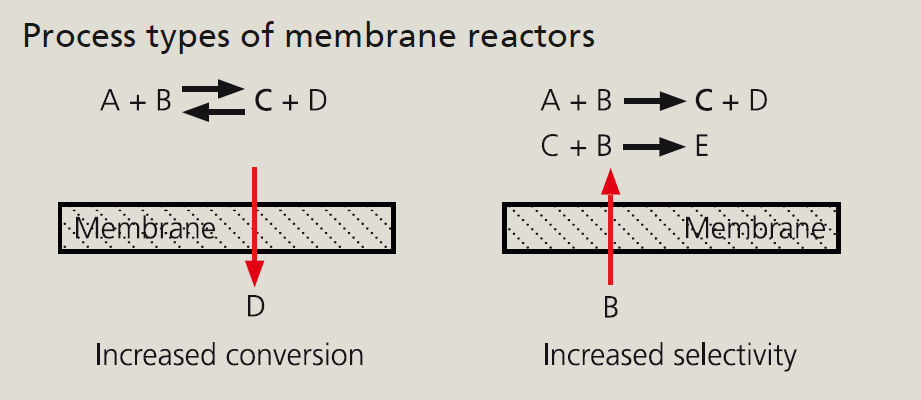

Many chemical processes are limited either by reaction kinetics or thermodynamics. In the latter case it is the chemical equilibrium that limits the conversion. The fact that by-product D is removed continuously means that the equilibrium is shifted towards product C. In the first case, educt B tends to react further with target product C. One example for this is a partial oxidation where complete oxidation needs to be avoided. The targeted dosing of one of the reactants – e.g. the oxidant – helps to suppress further reactions and increase the selectivity of the process. In both cases the process window can be extended by using a membrane reactor (see “Process types of membrane reactors”).

Current research at Fraunhofer IKTS

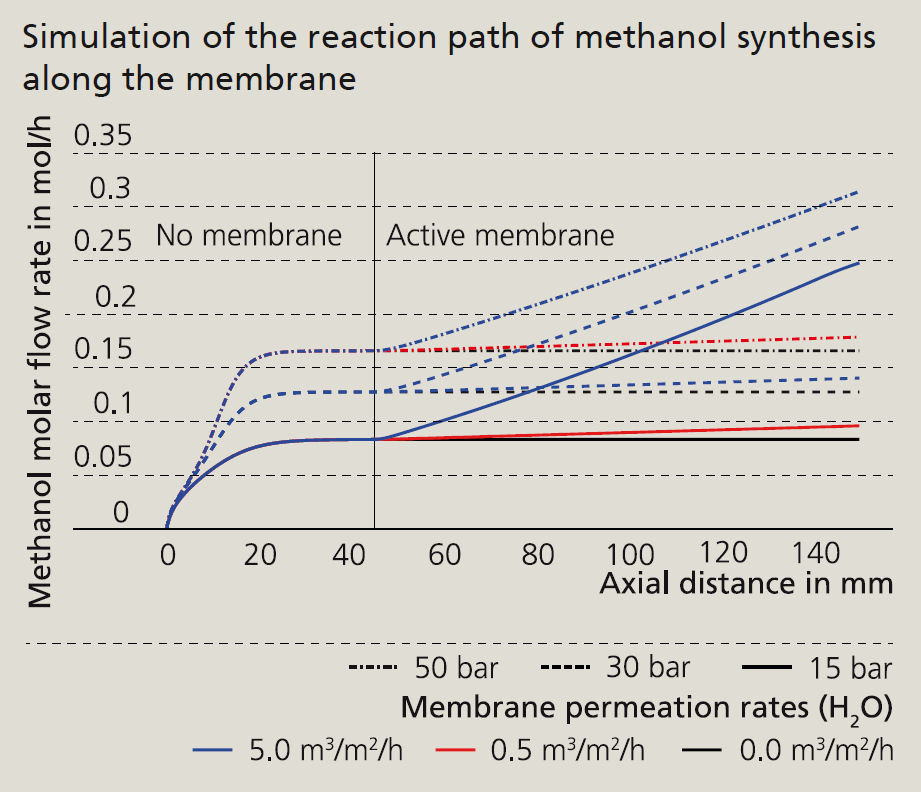

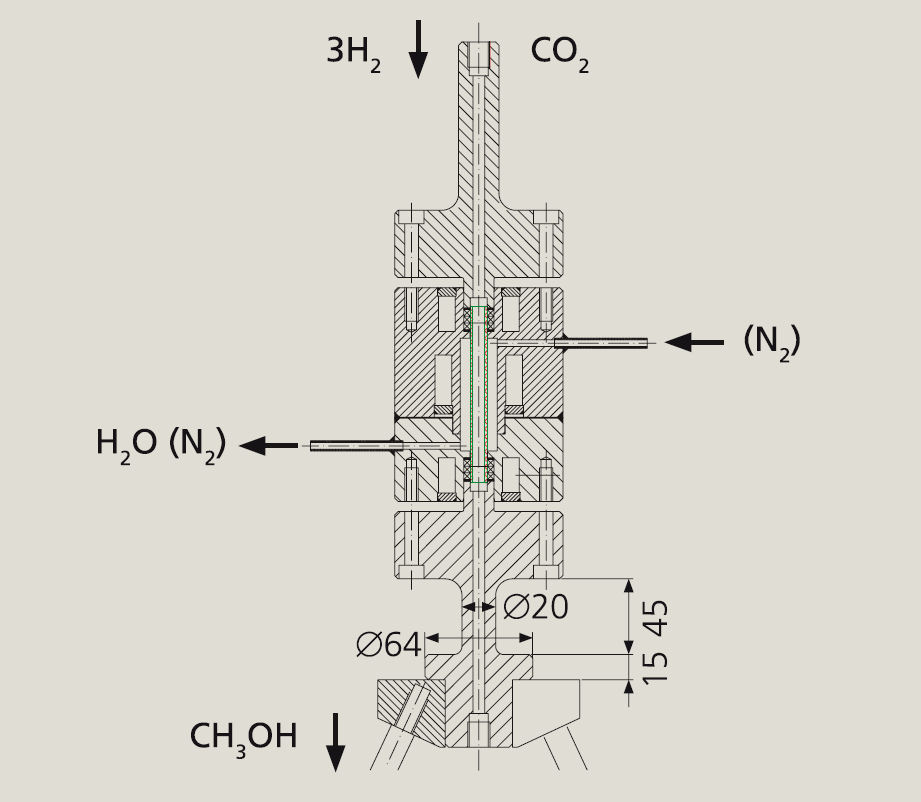

The successful development of processes with membrane reactors requires the combination of several skills (mastering catalysts, membranes, processes, process simulation and construction), which are all available at IKTS within the “Thüringer Forschergruppe Membranreaktoren”. Membranes with according properties for use in different kinds of membrane reactors are being developed. Together with MUW Screentec GmbH we are working on a membrane reactor for methanol synthesis from hydrogen and carbon dioxide. Process simulations prove a significant increase in methanol yield (see “Simulation of the reaction paths”). After proof on principle of the membrane reactor further work is centered around membrane performance and process development.