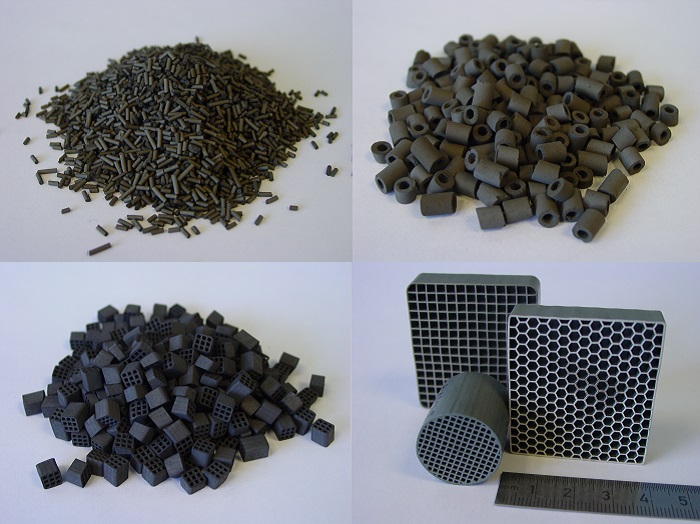

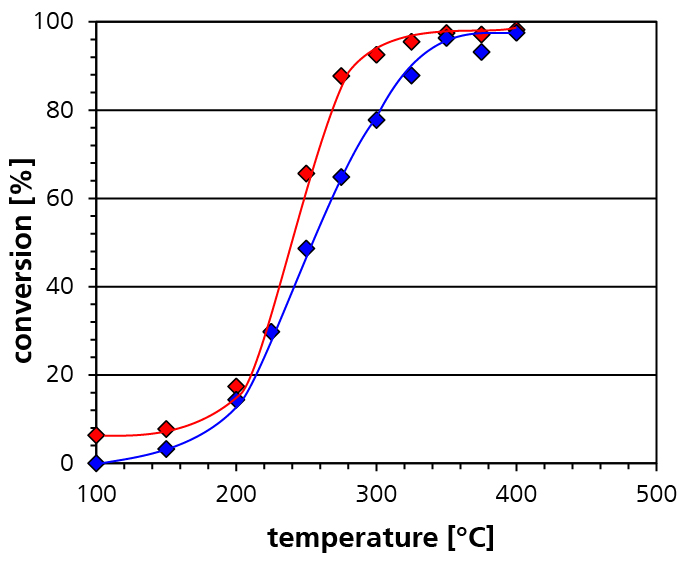

The team develops ceramic catalysts for heterogeneous gas-phase catalysis, especially for environmental protection, the treatment of industrial emissions (e.g. chemical industry, energy production, waste management) and industrial production processes. Applications range from direct catalytic decomposition, total oxidation and partial oxidation to selective catalytic reduction. Due to the existing material know-how and the in-house possibilities for synthesizing these materials it is possible to identify, produce and characterize tailored catalyst solutions. The characterization of conversion, selectivity, and yield under operating conditions is carried out in the catalysis laboratory at different test benches via FT-IR and GC. It is possible to mix and to meter complex model gases. In order to display the industrial processes close to reality in a laboratory scale (variation of gas mixture, gas hourly space velocity, pressure, temperature) the geometry of the samples can be adjusted accordingly (powder, granules, pellets, miniliths, honeycomb structures, foams and the like). Emphasis is put on the development of materials in order to increase the catalytic performance. By intergroup communication catalysis activities are coupled with membrane activities in order to investigate and develop catalytically active membrane reactors. The so-called membrane reactors enable a shift of the chemical equilibrium and therefore the enhancement of selectivity and yield via directed dosing of reactants or separation of certain reaction products.

Services offered

- Heterogeneous gas-phase catalysis

- Laboratory scale catalytic measurements (chemical equilibrium) close to reality up to 900 °C, increased pressure possible

- Calculation of conversion as well as selectivities and yields

- Materials synthesis and shaping (see preparation of ceramic precursors / shaping of ceramic components)

- Measurement of powders, granules, pellets, miniliths, honeycomb structures, foams and the like

- Enhancement / development / characterization of ceramic catalysts

- Coupling of catalyst and membrane („membrane reactor“) in order to increase the yield

- Construction of specially suited test-benches

Technical equipment

- Mass flow controllers for mixing and dosing of different gases and mixtures

- Evaporator for liquids

- different reactors

- FT-IR for gas-phase analysis (long-way-cell, one-way-cell)

- FT-IR for analysis of liquids and bulk materials (ATR, DRIFTS)

- GC/MS

- process-micro-GCs

- TPD (Zirox-cells, Oxylyt)

- Safety system

Examples and references

Catalyst and O2 carrier system for the processing of tar-containing gases.