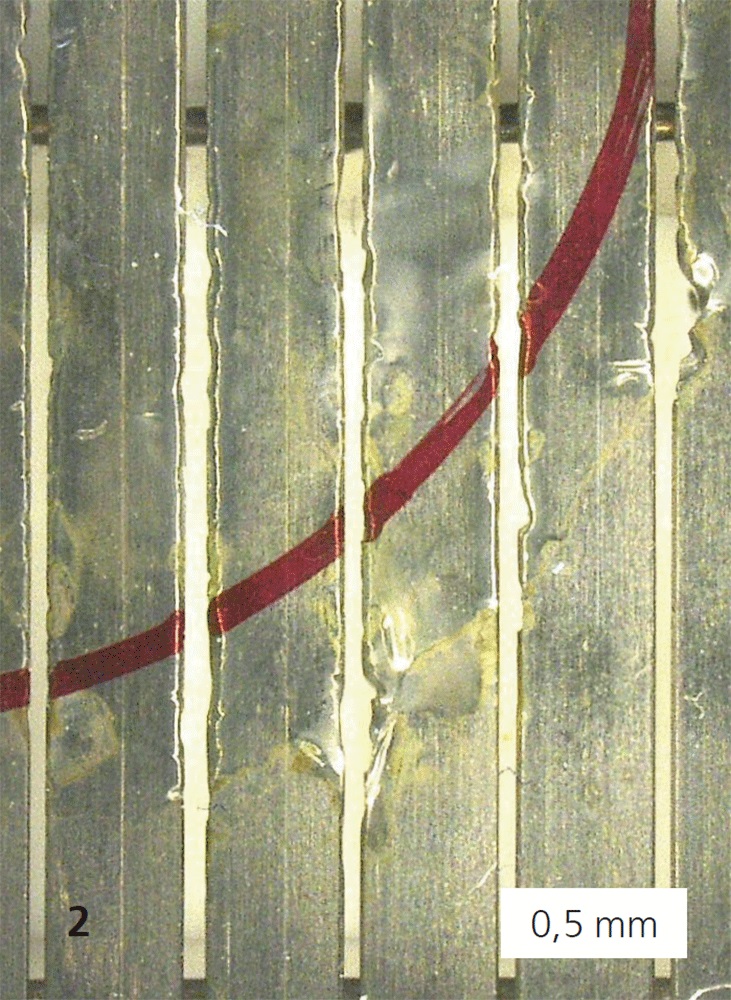

In oil, gas and geothermal wells, wire-wrapped sand screens prevent the input of mobilized formation particles into boreholes. The screen openings must have an exactly defined size in order to control the ingress of sand. If the filter fails, there may be permanent entry of solids or a decrease in production due to significant pressure drops in the area near the borehole. During operation, installation and workover measures, erosion, corrosion, deformation and blockages can lead to failure of the filter. Particularly in the initial phase, severe corrosion and hot spots arise, which can destroy the filter. Against this background, Fraunhofer IKTS was involved in a ZIM cooperation project for the coating of wire-wrapped screens with ceramic or carbon-enriched protective layers in order to optimize the flow conditions and increase the service life of the filters. While maintaining the defined gap width of the filter, ceramic and hardmetal layer systems were developed for wire-wrapped screens, making them more resistant to erosion and corrosion on the outside. Wire-wrapped screens have a diameter of approximately 40 to 200 mm and consist of segments with 4 to 6 m in length. In addition to high wear resistance, the requirements placed on the coatings are high chemical resistance to organic acids and a pH value of 4 to 8. The working temperature range is between -30 and +160 °C. The loads vary depending on the place of use and the raw material. Particularly challenging were the very precise gap dimensions and the special shape of the profile wire of the filter. The gap widths are

in the range from 100 to 500 μm ± 25 μm and must also be guaranteed with the coating layer.

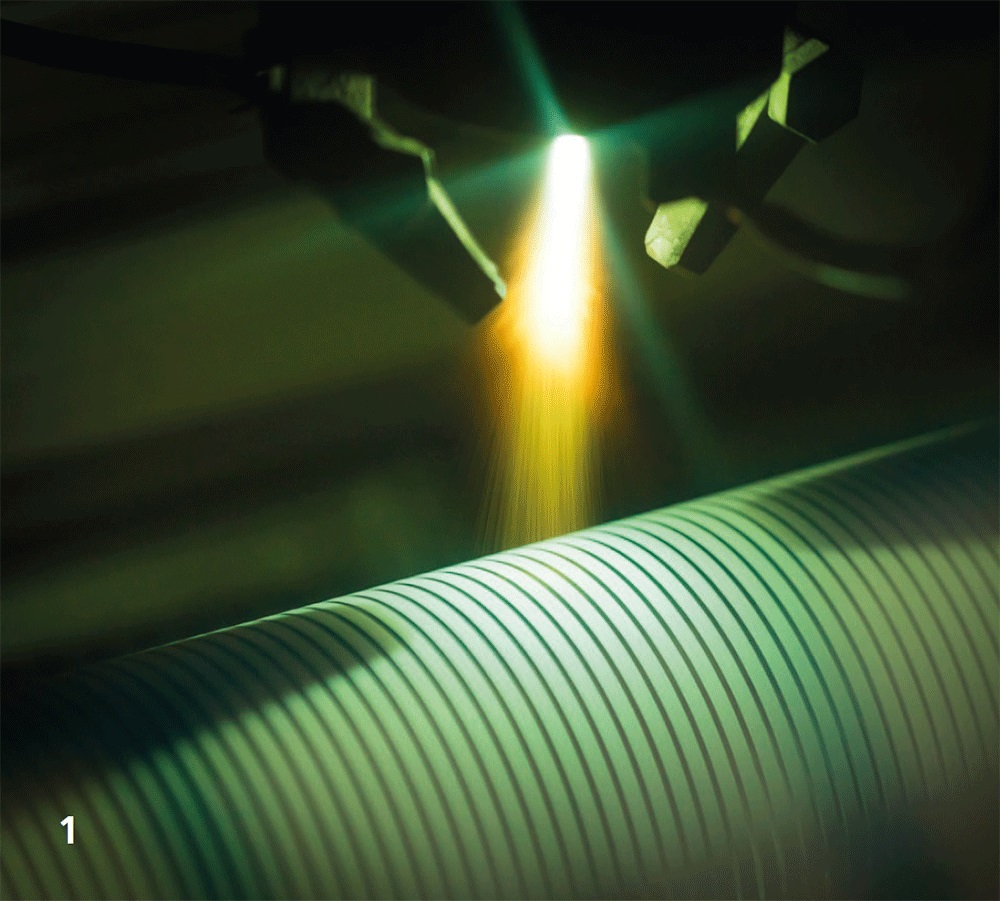

Several steps were necessary for the complex coating of wirewrapped screens. First, the outside of the filter was pretreated in a defined way to achieve high mechanical adhesion of the layer. Next, a so-called adhesive layer was applied by thermal spraying. Only then could the erosion-resistant functional layer be applied, also by thermal spraying. In the project, 23 coatings based on oxide-ceramic, nitridic and carbidic materials were sprayed, examined and compared regarding torsional and adhesive strength as well as corrosion and erosion. To increase corrosion resistance, a sealer developed at IKTS was ultimately applied. The wetting properties of the coating can be influenced by selecting a particular sealer.

The wire-wrapped screens were developed and manufactured by our industrial partner, con-slot SCREENS GmbH. Our project partner TU Bergakademie Freiberg tested the samples in a specially developed test facility under conditions close to commercial application with regard to corrosion, erosion and chemical resistance. After successful completion of these investigations, early prototypes have been used in field tests in a gas well since September 2020.