Green revolution on the high sea – EU project HyMethShip

Current research

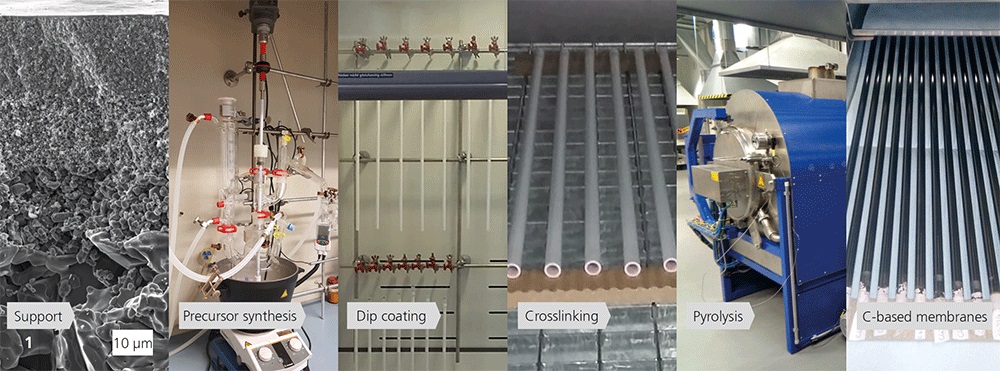

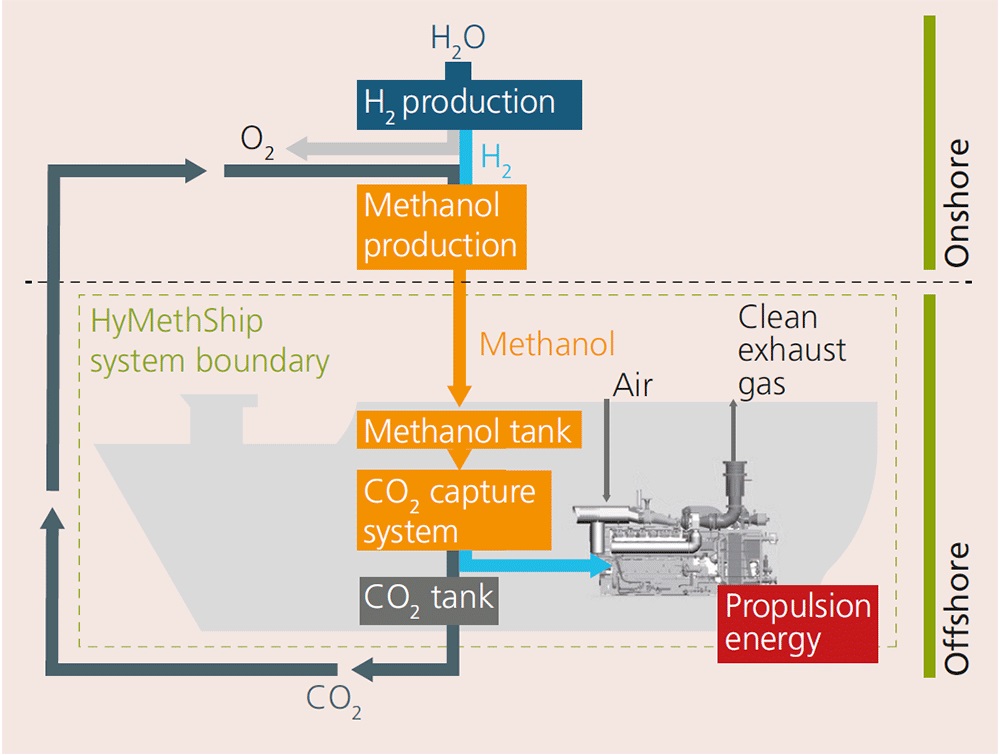

A visionary, safe and environmentally friendly concept for the propulsion of ships is the research subject of Fraunhofer IKTS scientists at the Hermsdorf site in collaboration with partners, such as the Meyer Werft shipyards, engine manufacturer INNIO, ship operator EXMAR as well as certifier Lloyd’s Register, amongst others, within the Horizon 2020 EU project HyMethShip (GA-Nr. 768945), which is coordinated by LEC Graz. The aim of the project is to reduce shipping emissions by up to 97 percent by using hydrogen for the engine. Said hydrogen is generated on board by reforming methanol. This concept is especially relevant in the context of ships, as seagoing vessels traditionally burn heavy oil, which causes sulfur compound emissions. Furthermore, diesel is used for routes along coastlines, resulting in emissions of nitrogen oxide and CO2. This can be avoided by using the new propulsion concept. Sulfur compounds do not occur, nitrogen oxides are minimized, and the CO2 produced is captured, stored on board and therefore not released into the atmosphere. The propulsion system works as follows: The ship is fueled with methanol onshore, which, in contrast to hydrogen, can be stored easily and poses no threat to the environment even in the case of a complete tank spill or drain. Methanol serves as a liquid hydrogen carrier. Aboard the ship it is converted with water by steam reforming. During this process, hydrogen is obtained via membrane separation and burned directly in the engine for ship propulsion. Significantly more hydrogen is generated than is stored in the methanol itself, because the water also provides additional hydrogen according to the reaction CH3OH + H2O → 3 H2 + CO2. Additionally, CO2 is produced, which is stored aboard and drained on return. Onshore, it can then be used for methanol synthesis once again – thus completing a closed-loop propulsion system. The heat needed for this endothermic process comes from the engine, which further increases efficiency. In HyMethShip, IKTS is tasked with the complete process and reactor design as well as the preparation of the membranes at a technical scale with a membrane area > 5 m². A demonstration unit with more than 1.6 megawatts hydrogen energy will be installed at the Technical University of Graz. Initial test runs are planned for the start of 2021 and trial operation will follow by mid-2021. Furthermore, the consortium will compile a study for a Scandinavian ferry based on the novel propulsion system with 20 megawatts of power. For comparison: an oil tanker has a power of 50 to 80 megawatts.