Any ceramic shaping requires raw powders with adapted properties. Amongst others, application criteria are phase purity, phase composition, grain shape and grain size distribution as well as impurities and contaminations.

Mixed conducting materials and catalysts show frequently an increased chemical reactivity. According to that, special conditions have to be kept during preparation and further treatment of these powders and precursors. Additionally, powder amounts demanded for special purposes are very low in general. For that reasons, the majority of special raw products are not commercially available. Moreover, powder preparation described in literature is often limited to batch sizes of few grams.

Therefore ceramic powders and precursors are synthesized in-house by applying various preparation methods. Batch sizes up to 5 kilograms can be realized. Afterwards these powders can be shaped and characterized according to their functional properties in-house (e.g. membranes, catalysts, …).

Preparation methods

Modified solid state reaction

Reactive precursor compounds, e. g. amorphous oxides, hydroxides or carbonates, will be mixed by milling. The following thermal treatment adapted to the aimed phase composition is realized in one step.

Precipitation technique

Homogeneous solutions are dropped into a precipitation agent or vice versa. The precipitated product will be washed, dried and calcinated. Different phase compositions and different grain size distributions can be produced depending on the reaction conditions. Special methods, such as sol-gel-processes are possible (small scale).

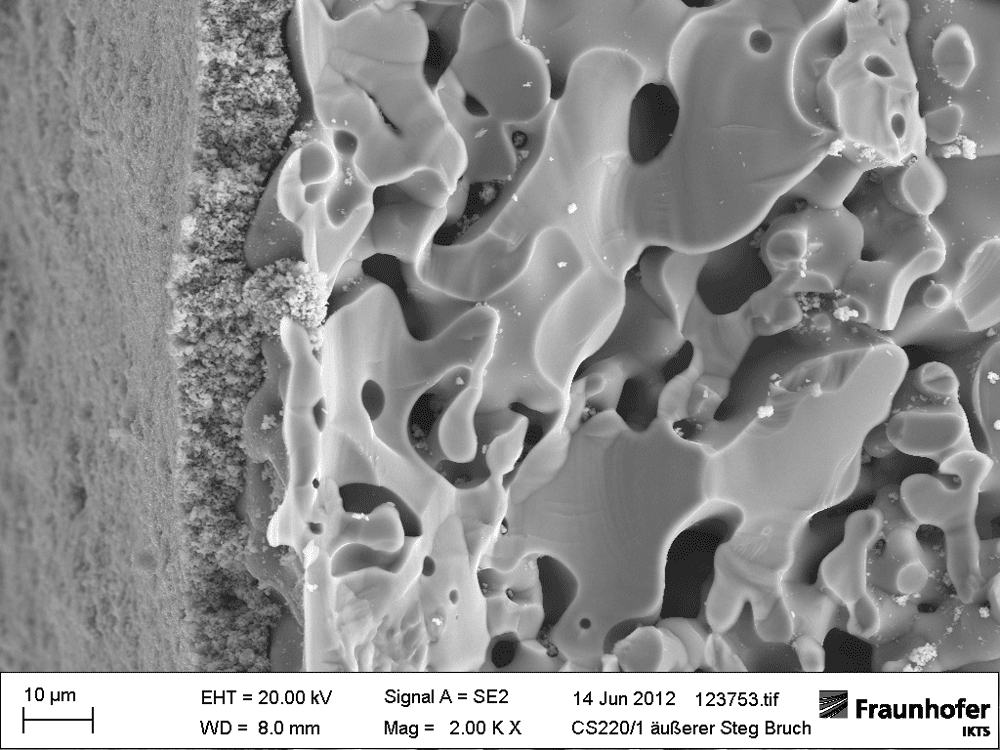

Grinding techniques

Depending on the powder amount, the grain size aimed and the powder properties different types of mills are used for dry and wet grinding.

Combustion synthesis

Precursors are converted during highly exothermic reactions (self-propagating high-temperature synthesis) into powders with unique properties (small scale). Flame pyrolysis is also possible.

Services offered

- Preparation of new and common ceramic powders with well-defined compositions

- Verification and optimization of phase composition and purity by XRD assisted by Rietveld analysis

- Verification and optimization of granulometric properties such as grain size distribution and specific surface area by application of different preparation methods and/or application of different grinding technologies

- Characterization of powder suspensions: rheological analysis, determination of streaming and zeta potential and the dependency on pH value and on dispergator concentration

- Coating technologies