Sub-µm and nanotechnologies for components associating highest hardness and wear resistance with an extreme thermal and chemical stability

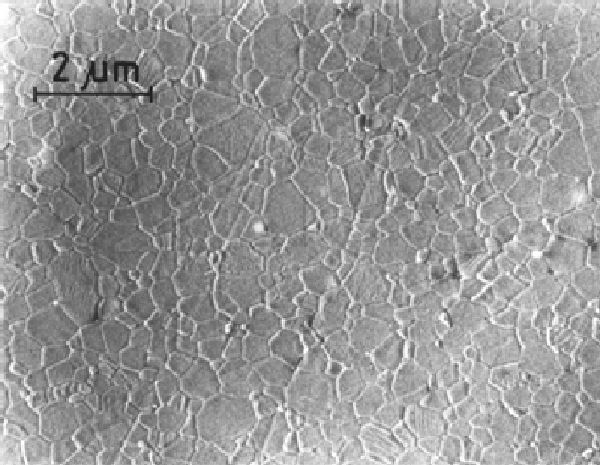

Known components made of hardmetals, Si3N4 or TiC-reinforced composites exhibit a limited stability in agressive environments because of metallic, glassy or oxidizing constituents, Zirconia ceramics are less hard and their microstructure and strength critically depend on the temperature. The new sub-µm corundum ceramics (Fig. 1) avoid these shortcomings, and their hardness surpasses all grades addressed above.

Advantages

- Extremely high hardness (Fig. 2)

- Significantly improved wear resistance (Fig. 3)

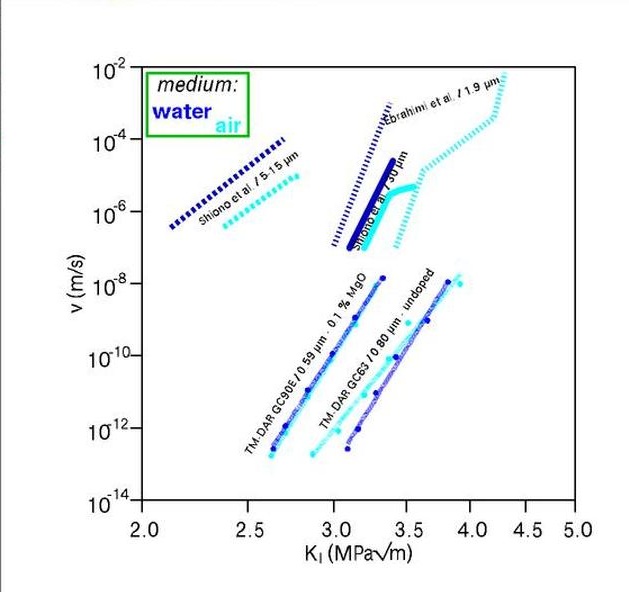

- Reduced aging in aqueous media compared with advanced commercial grades of sintered corundum (Fig. 4)

- High strength (600-850 MPa), nearly constant up to about 1000 °C

- High chemical stability in acids, bases, and agressive gases.

Subcritical crack velocity of sub-µm Al2O3 ceramics in water and in air compared with conventional grades: evidence of an outstanding high reliability of the new sub-µm ceramics in aqueous media.

Products and services offered

- Development of high-purity ceramics on the basis of corundum (α-Al2O3) with sub-µm/nano microstructures for wear resistant components

- Alternative development with commercial or with nanoscale raw materials

- Technological investigations for upscaling supporting the development of new products; screening of raw materials and shaping approaches

- Investigations of the technical performance in various applications