Batch production of fine scaled piezoceramic components with defined alignment is of great interest for many sensor and actuator applications.

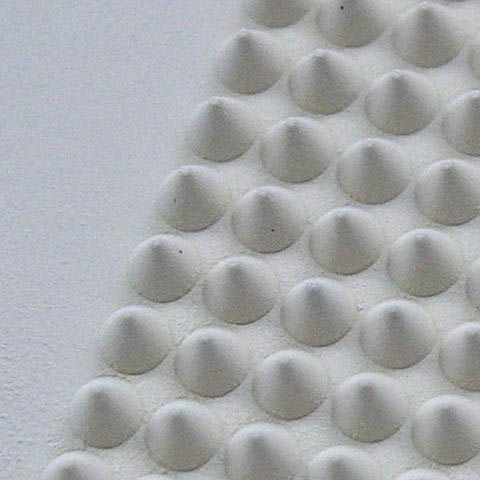

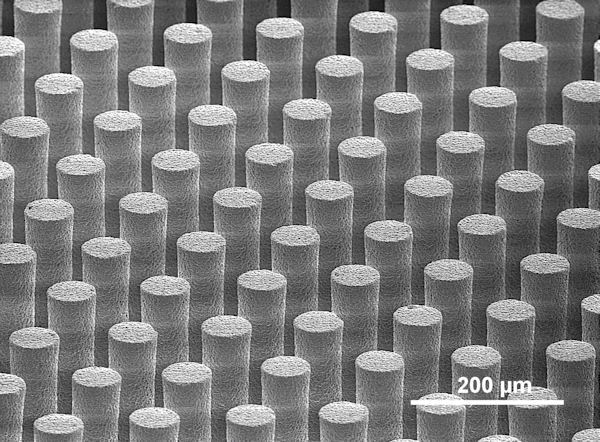

The soft-mold-process developed at the Fraunhofer IKTS allows for cost-effective production of piezoceramic microstructures with high aspect ratio (6:1). Depending on the master mold design arrays of regular or irregular arranged piezoceramic components (cuboidal, cylindrical, and cone-shaped) can be formed via slip casting. Microstructures based on lead zirconate titanate (PZT) with edge lengths between 20 µm and 1000 µm and a maximum height of 500 µm could be prepared so far.

Services offered

- Preparation of piezoceramic microstructures for sensor and actuator applications

- Development of high frequency ultrasonic transducers on the base of 1-3 piezocomposites

- Characterization of piezoceramic transducers

Technical Equipment

- Slip preparation: planetary ball mills, agitated ball mills, roller mills, stirrer

- Molding: vacuum infiltration equipment

- Composite preparation: polymer infiltration equipment, lapping and polishing machines, sputter coater, screen-printer with semi-automatic positioning system

- Characterization: rheometer, microscopes, low signal measurements (dielectric constant, dielectric loss factor, electromechanical coupling coefficient), high signal measurements (ferroelectric hysteresis, voltage-deflection-curves, blocking forces, vibration behaviour), scanning laser vibrometer