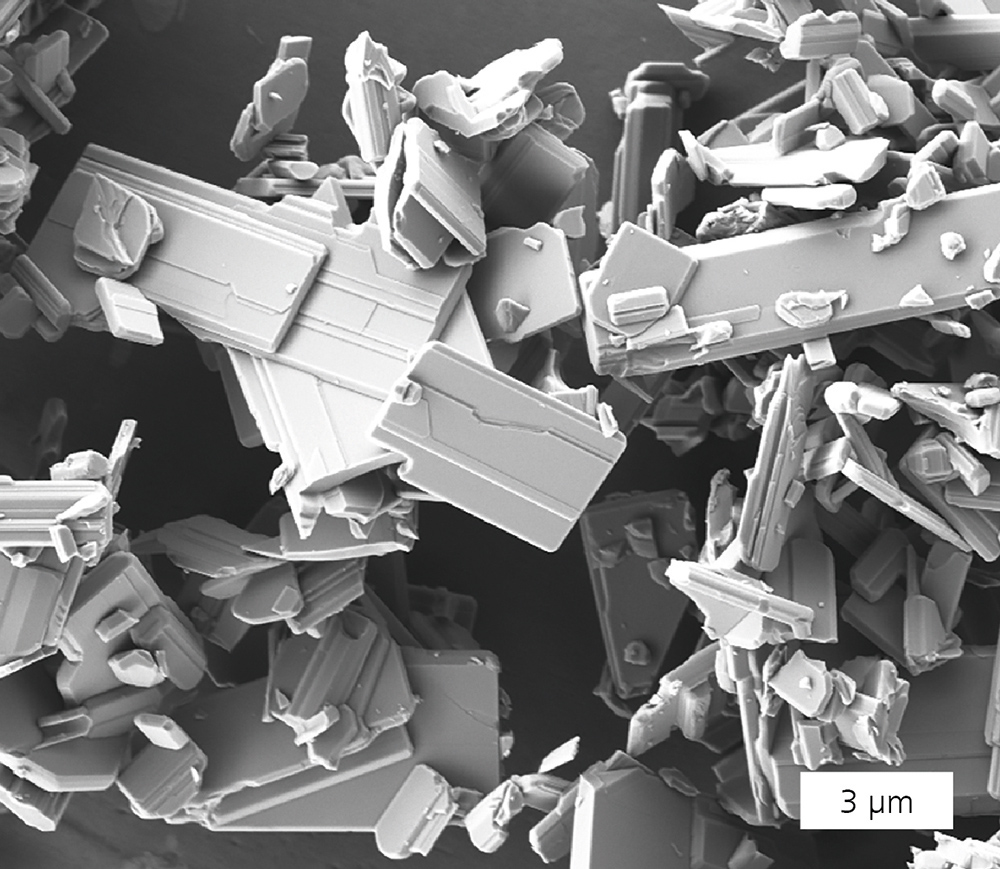

![FESEM image of epitaxially grown KNN on NaCa<sub>4</sub>Nb<sub>5</sub>O<sub>17</sub> templates with a [110] growth direction.](/en/departments/electronics_microsystems_biomedicine/smartmaterialssystems/multifunctional_materials_components/cr_layerd-perovskites_for_texturing_of_lead-free_piezoceramics/jcr:content/contentPar/sectioncomponent/sectionParsys/textwithinlinedimage_730308915/imageComponent2/image.img.jpg/1586858360604/FESEM-Aufnahme-von-epitaktisch-aufgewachsenem-KNN-auf-NaCa4Nb5O17-Template-mit-110-Wachstumsrichtung.jpg)

Piezotechnology has been very present for decades in the form of actuators, sensors, ultrasonic transducers or generators in various fields of applications. The most frequently used piezoceramic material is Pb(Zr1−xTix)O3 (PZT), thanks to its excellent electromechanical properties. However, its highly toxic lead content of > 60 wt % has long been inducing researchers to look for lead-free alternatives, more recently as a result of legislative pressure (ROHS 2011/65/EU). K1-xNaxNbO3 (KNN) has emerged as promising lead-free piezoceramics from this search, based on its strong piezoelectric properties and high Curietemperature. However, KNN materials are far less efficient than commercially available PZT compounds. The doping of compounds to texture the microstructure or the use of special sintering techniques can also help to improve piezoelectric performance. Thus, electromechanical properties that are comparable to PZT can be achieved.

Texturing of lead-free piezoceramic materials

Templated grain growth is often the method of choice for texturing the microstructure. This process uses platelet-shaped single crystal templates which have been inserted and aligned in the green compound through tape casting. Epitaxial grain growth on the single crystal templates leads to oriented grain growth during the sintering process, resulting in a textured microstructure. NaNbO3 (NN) templates are typically used for KNN ceramics. However, at present these can be synthesized by means of a cost-intensive and laborious molten salt synthesis process only, essentially preventing the industrial application of textured KNN.

Layered perovskites form platelet-shaped morphologies based on ordered defect structures in their crystaline composition and could therefore qualify as potential candidates for templates. They are easy to produce via a mixed oxide route. Another advantage is the large range of available layered perovskite compounds. This means that it is possible to introduce not only a [100] texture direction into the microstructure – as is the case with NN templates – but also [110] or [111].

At Fraunhofer IKTS, several layered perovskites have been developed and investigated as possible template systems for texturing KNN ceramics. Based on microstructural analyses, it was shown that KNN particles grow epitaxially on NaCa4Nb5O17 templates and exhibit a [110] growth direction. It was thus possible to show for the first time that layered perovskites are suitable for texturing KNN materials. Further challenges on the path to finally achieving a textured KNN microstructure are template size and stability of the layered perovskites, quality of the green bodies as well as sintering conditions.