Single-fiber transducers for 3D-ultrasound-computer tomography (USCT)

Current research

Imaging for breast cancer screening

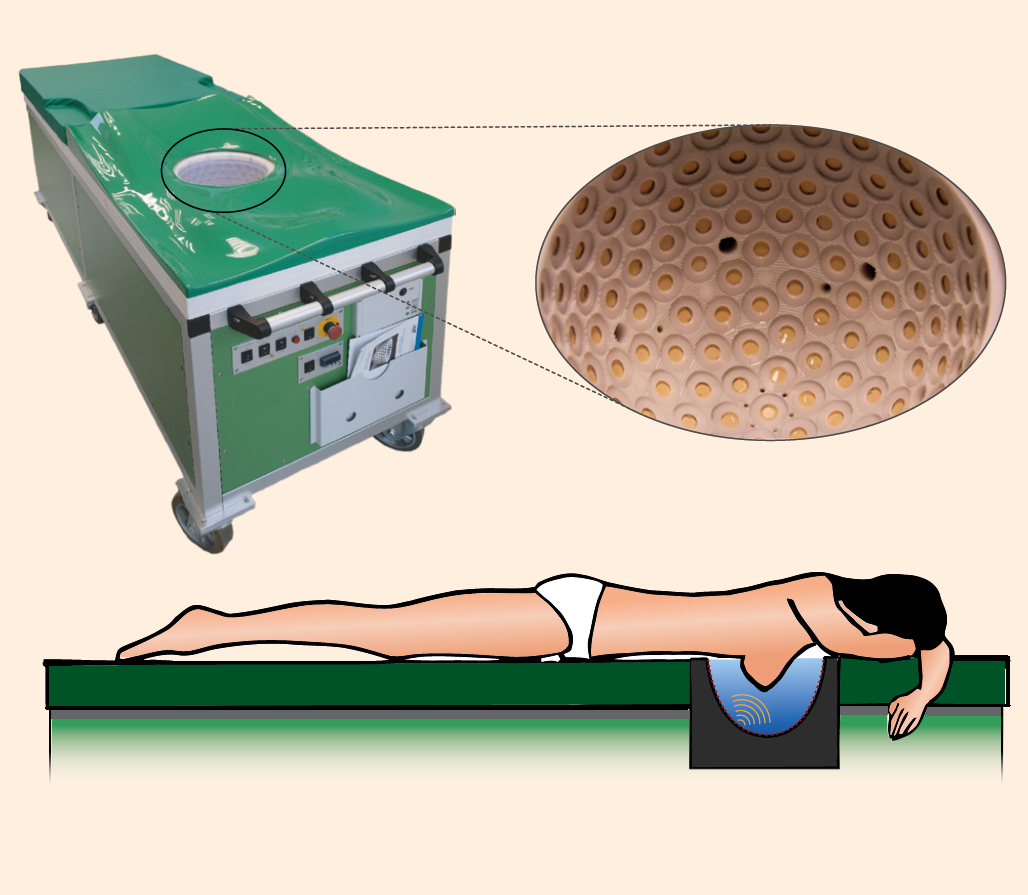

3D-ultrasound-computer tomography (USCT) systems use ultrasound waves for creating multiple-plane cross-sectional images. They are especially interesting for the early detection of mamma carcinoma in breast cancer screening. Compared with X-ray mammography, conventional ultrasound, or magnetic resonance imaging (MRT), USCT is characterized by high sensitivity and specificity. Moreover, moderate equipment costs and the fact that the systems work without ionizing radiation support this technology for future imaging purposes. However, the configuration of USCT systems is complex. The system operates a large number of ultrasonic transducers in a semi-spherical aperture surrounding a region of interest (ROI) in repeated patterns. For the ROI to be scanned homogeneously, the transducers should exhibit large opening angles and high sensitivity and bandwidth while showing only little property variations among each other. Where such requirements have to be met, established ultrasonic transducer manufacturing technologies quickly reach their limit.

Ultrasonic transducers based on piezoceramic fibers

Fraunhofer IKTS has developed a purpose-built ultrasonic transducer technology which takes into account the specific requirements of 3D USCT systems. Ultrasonic transducers based on this technology were integrated and tested within a 3D USCT system of the Karlsruhe Institute of Technology (KIT). They are based on piezoceramic fibers with circular cross section. The fibers are made from a ceramic slurry by a spinning process in which the slurry is extruded continuously through a nozzle into a precipitation water bath. After spinning, the fibers are cut to length, dried and sintered before being arranged in a well-defined pattern and embedded in epoxy resin. The cured block is diced into discs of identical thickness. Each single piezoceramic fiber in the disc works as an individual addressable ultrasonic transducer, therefore called a single-fiber transducer. By preventing the periodic near-order arrangement of fibers, resulting images show an improved signal-to-noise ratio. The thickness of the piezocomposite discs is chosen according to the desired working frequency. The single-fiber transducers thus manufactured had opening angles of 50° – an increase by the factor of close to 1.5 compared with conventional transducers manufactured by a dice-and-fill process. The transducers designed and manufactured for KIT’s 3D USCT system work with a frequency of 2 MHz and use piezoceramic fibers of 460 μm diameter. The described technology is scalable over a large geometrical and frequency range. For that reason, it is not limited to medical USCT applications but can also cover similar applications in which a large number of identical ultrasonic transducers have to be arranged in regular patterns.