Printed ultrasonic transducers for medical imaging and non-destructive testing

Current research

Ultrasonic transducers are widely used for medical imaging and non-destructive testing. Current research activities focus on improved image resolution, progressive miniaturization, and increased electronic density.

Phased arrays have become the preferred technology for diagnostic imaging. With these solutions, the active piezoelectric plate is divided into several elements, which can be activated and read out separately. This allows for electronic scanning, steering and focusing of the ultrasonic beam.

Conventional manufacturing technologies for ultrasonic probes are based on different dicing and mounting steps, which are complex and time-consuming. Additionally, adhesive layers as well as solder and bond pads can influence acoustic emissions.

Cost-effective manufacturing on a large scale

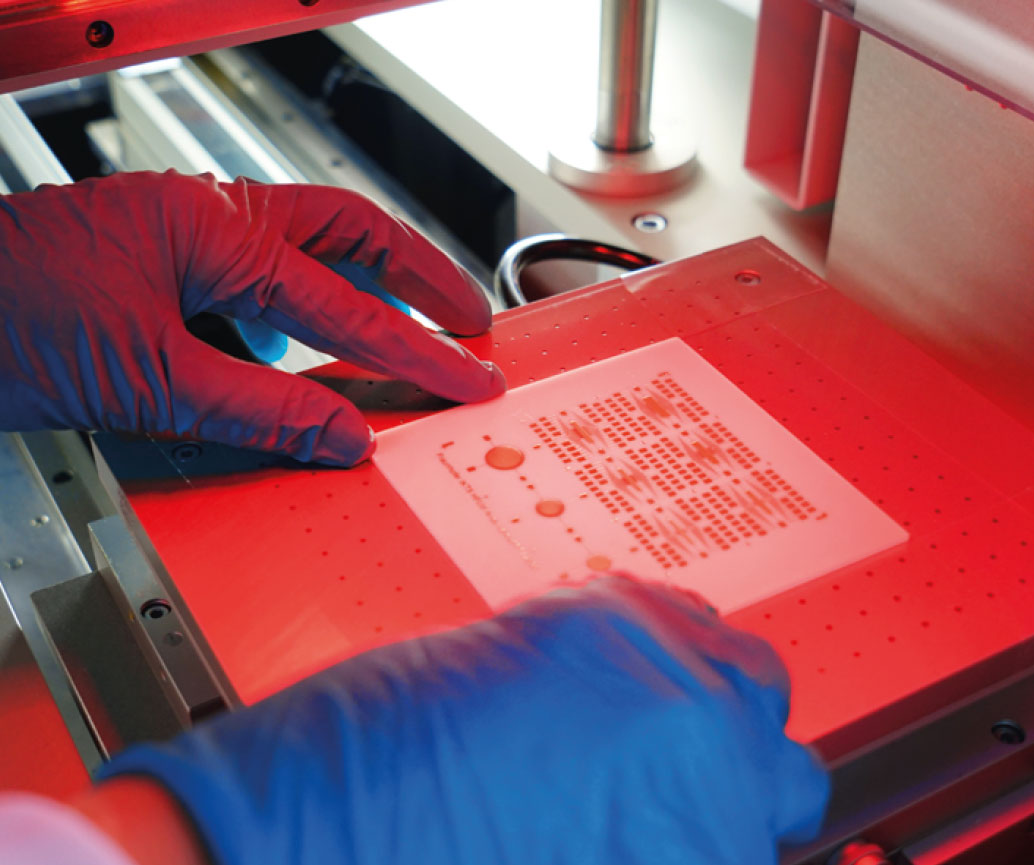

Fraunhofer IKTS has recently developed a novel manufacturing route for ultrasonic transducers based entirely on printing techniques. At the heart of the technology are piezoceramic thick films which are applied on planar or tubular substrates through screen-printing.

The design of the ultrasonic transducer is defined by the printing pattern, or more precisely the screen openings through which the thick film paste is applied. This happens very fast and with high reproducibility.

The performance of an ultrasonic transducer is influenced not only by the piezoceramic thick film itself, but also by the substrate material, the electrode design, and the acoustic matching layers. Materials have been developed for this porous substrate which directly serve as backing material for damping acoustic delay lines.

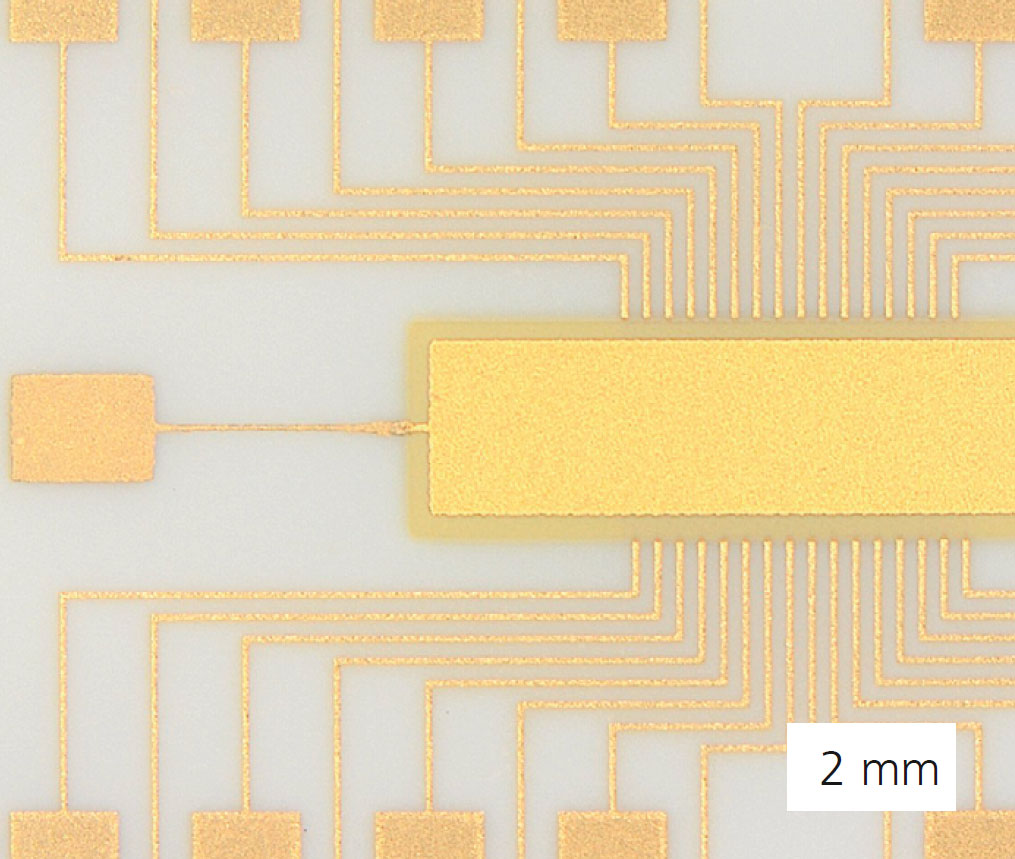

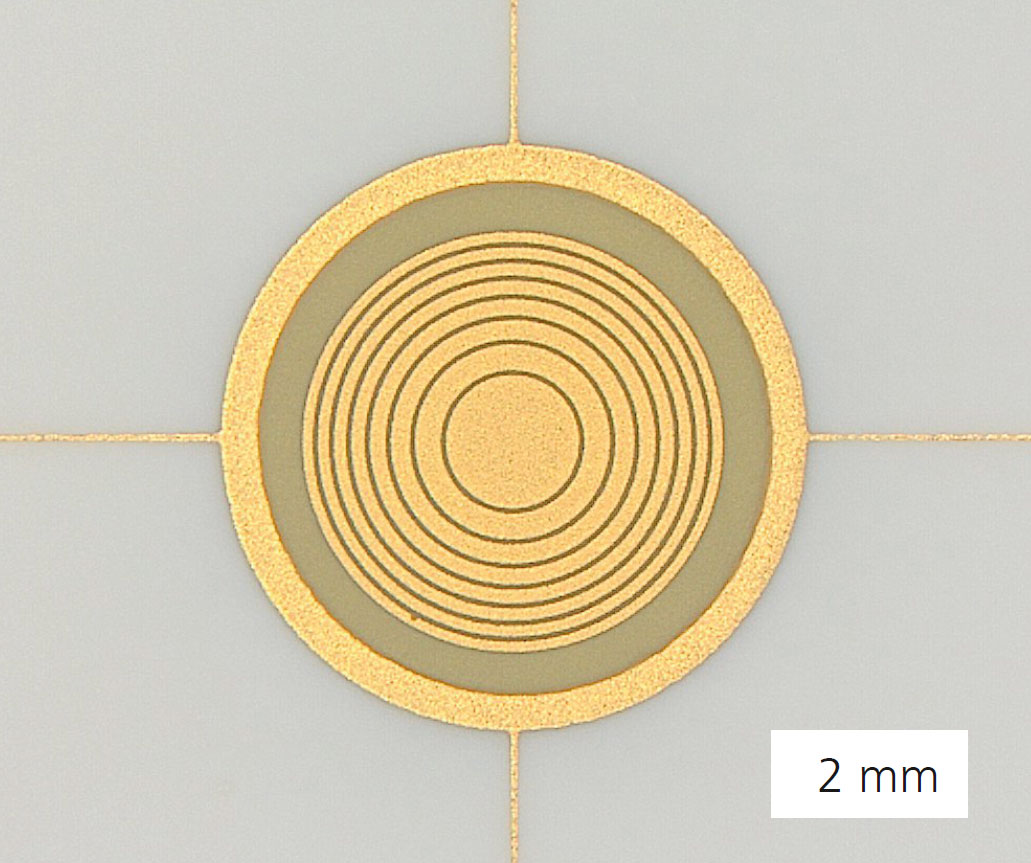

The array design is mainly defined by the printed electrodes, where lines with 70 μm width and 120 μm pitch are possible through screen printing, allowing for the cost-effective production of ultrasonic transducers with working frequencies of 10 MHz for linear arrays and 40 MHz for annular arrays. Moreover, it is possible to apply acoustic matching layers by pad printing to improve the transmission of ultrasonic waves into water or tissue. The printed ultrasonic transducers are free from interfering adhesives and offer the advantage of three-dimensional packaging with printed electrical contacts on top or inside the substrate material (for instance by using ceramic multilayer substrates). This eliminates the need for voluminous solder or bond pads and improves the resonance behavior. The printed ultrasonic transducers are very compact and thus meet the requirements for miniaturization, price reduction and high functional density, making them ideal for applications in mobile devices, such as smartphones.

Acknowledgement

The work was supported by the German Ministry of Economic Affairs and Climate Action (BMWK) within the Industrial Collective Research project 20099BR of the German Ceramic Society DKG via AiF.

Supported by