For many different applications that require materials combining high hardness and high toughness, hard phase-based metal matrix composites (MMC) are used. Among these are hardmetals, which are used for drilling, cutting, and machining as well as for different shaping tools (e.g. pressing dies, extrusion tools). Other examples are thermally sprayed hardmetal coatings or wear parts produced by means of metal melt infiltration. In all these applications, only hard phase grains or particles consisting of one or two hard phase composing elements are currently used, such as tungsten in tungsten carbide, titanium in titanium carbide or titanium carbo-nitride and silicon in silicon carbide.

Multi-element hard phases

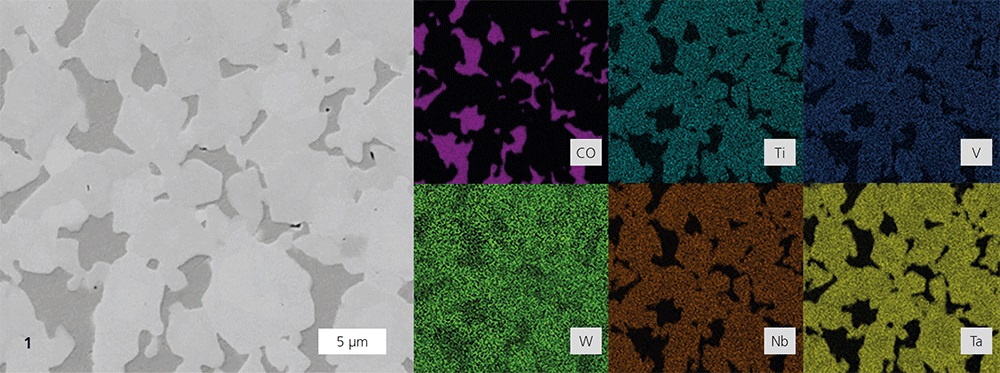

The new multi-element hard phases developed at Fraunhofer IKTS, so called high entropy hard phases (carbides, nitrides or carbo-nitrides), consist of several carbide forming metal atoms with equi-atomar composition. This makes it possible to use novel hard phase particles, some of them with higher hardness and adjusted thermal conductivity compared with single-element hard phases, for different applications.

High entropy hard phase composite materials

By mixing and subsequent sintering of the high entropy hard phase particles with ductile metal particles, such as cobalt, nickel or iron-based alloys, novel high entropy hard phase composites (patent pending) can be produced. Because of the high stability of the high entropy hard phases, the carbide forming elements do not fully dissolve within the metal matrix but remain to form a very hard hard phase skeleton. The chemical elements suitable for high entropy hard phase particles all come from the fourth to sixth subgroup of the periodic table of elements. They are, among others, Ti, Zr, Hf, V, Nb, Ta, Cr, Mo, and W. Based on their design, which requires at least four of these elements, plus carbon or nitrogen as carbide or nitride formers, a large variety of high entropy hard phases can be realized. By mixing with the mentioned ductile metal particles, a targeted design of adjusted mechanical as well as thermo-physical properties, such as hardness, fracture toughness, electrical and thermal conductivity, can be achieved. An advantage over conventional hard phases is that the phase design now allows the substitution of tungsten carbide, which is classified as a critical raw material (CRM) among hardmetals. Furthermore, it is expected that the use of high entropy hard phases will increase the service life of tools and reduce the consumption of resources as well as resource dependency. The levels of fracture toughness (up to 8.5 MPa*m1/2) and hardness (up to 1450 HV10) reached presently are comparable with conventional tungsten carbide cobalt-based hardmetals or titanium carbonitride nickel-based cermets. With further developments and research work, these properties are expected to be strengthened even more. We plan to develop and validate these novel composite materials further by means of public co-funded projects.