Tools and components made of hardmetals, ceramics and ultra-hard materials are becoming ever more popular thanks to their high wear and temperature resistance, finding acceptance in areas where until recently high-speed and tool steels were preferred. We can guide you through this transition, pointing out special aspects and errors when it comes to the erosive machining, milling or soldering of these hard materials, which are also more brittle and prone to cracking. In most cases, merely replacing the current steel component with hardmetal will not do. If the design is not adapted for hardmetal, the potential advantages of substituting the materials will generally not be realized.

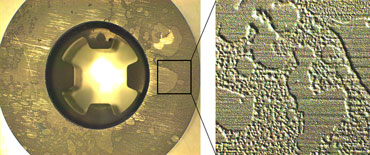

The upper image shows the surface of a component made of hardmetal, which was damaged during erosive machining. Most of the time, such undesired effects are not so much due to quality defects within the hardmetal, but rather to improper processing.

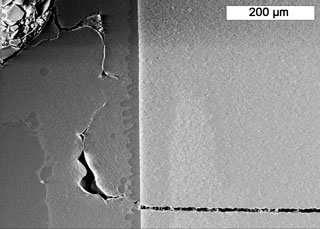

When using hardmetal as cutter or wear protection parts in drill bits, sawing blades etc., joining technology plays an important part. However, if the conditions are not right, the properties at the surface of the hardmetal can change and soldering stress can occur, which may lead to the destruction of the hardmetal.