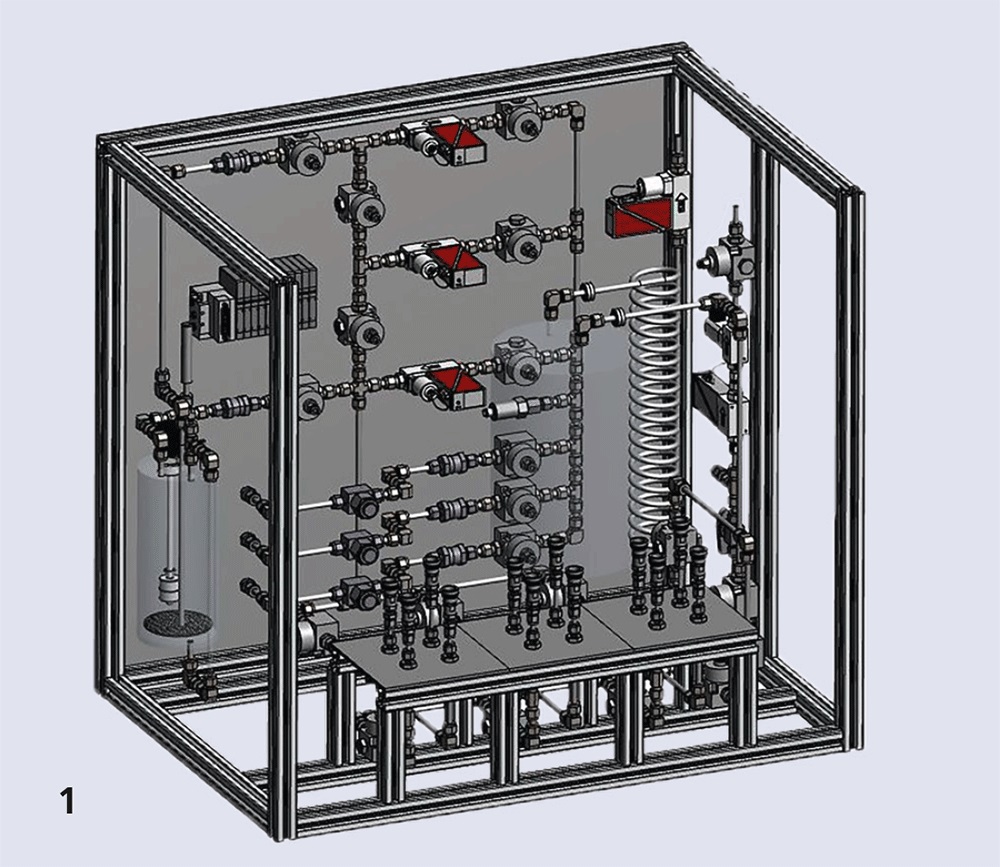

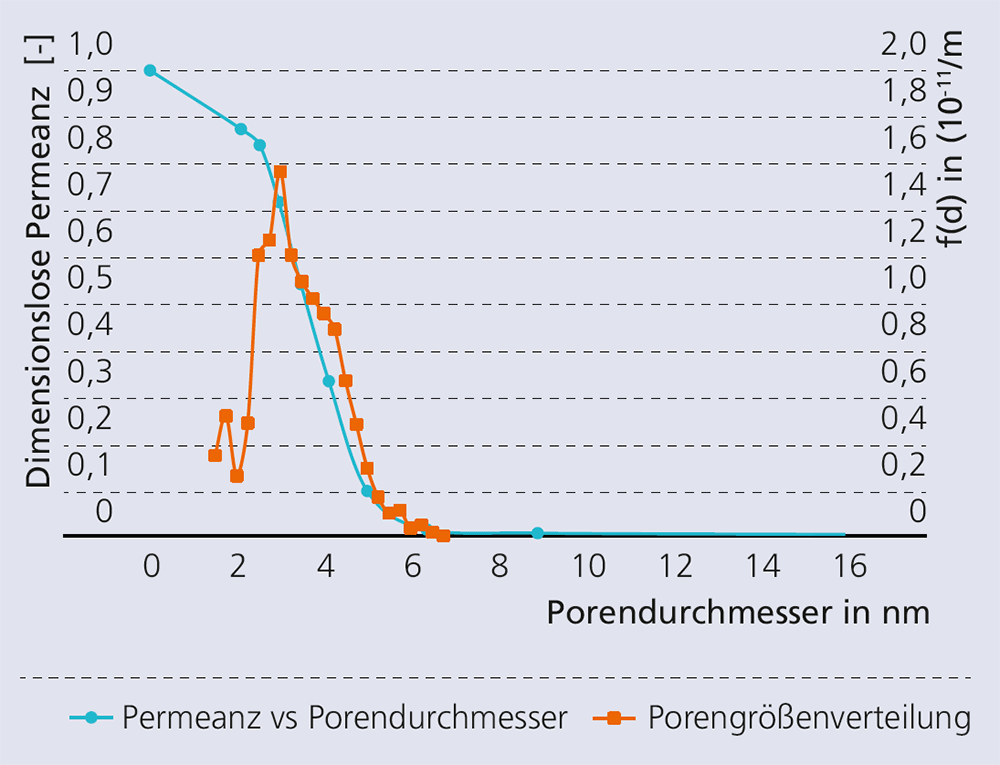

When developing and producing porous ceramic membranes, information on the pore size distribution and the absence of defects in the active separation layer is of great importance. Conventional analytical methods (mercury porosimetry, nitrogen sorption, SEM, determination of molecular weight cut-off, etc.) require the preparation of a special test sample or cause irreversible damage to the membrane. Permporometry, a relatively new measuring method, allows non-destructive analysis of defect pores and pore distributions in mesoporous membranes. Fraunhofer IKTS has for several years been successfully using a self-developed and mostly manually controlled permporometry plant for membrane characterization. This has now been supplemented by a fully automated version, which was also developed and built at IKTS. This system allows for a considerable increase in measuring capacities. Up to three membrane modules can be installed simultaneously. Three gases (standard nitrogen, argon and helium) can be used for the measurements and can also be changed automatically during the measurements. By using optimized pipe dimensions and a precise automatic pressure regulation system, it is possible to obtain much more precise measurement results in a shorter time. Different humidifying agents (e.g. water, ethanol, n-hexane) can be used. Dosing and temperature control are set automatically, ensuring high temperature stability and precise humidity adjustment. Thanks to the defined sequence control as well as the control and constancy of the operating points during the measurements, membrane characterization is faster and reproducible. Tubular membranes with meso- and microporous active separation layers of different geometries (internally and externally coated single- and multi-channel tubes, disks/plate membranes, etc.) can be analyzed.

The plant is an important tool for membrane characterization during membrane development. However, the process also shows great potential for use in quality control during membrane production, e.g. for determining characteristic gas flows under defined test conditions.