Mixed-matrix membrane for the extraction of a sustainable solvent from molasse

Current research

Green solvent from residues

Milk processing in Germany currently produces 12.6 million tons of whey per year. After the proteins and the lactose have been separated, a mother liquor (sugar-containing molasses) remains, which is expensive to dispose of.

In a research project with TU Dresden (AiF 20311 BR), a process for the fermentative production and membrane-based separation of ethyl acetate from mother liquor is under development. Microbially produced ethyl acetate is a sustainably produced solvent that can be used, for example, to produce green adhesives. It is easily microbially degradable and therefore environmentally friendly to use.

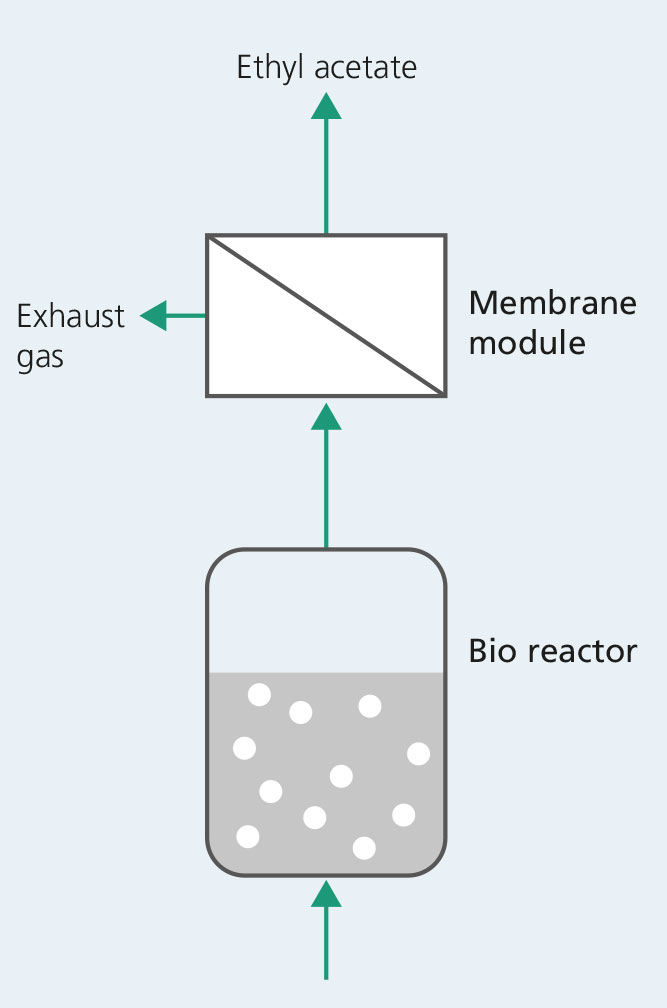

Membrane process for solvent separation from process exhaust gas

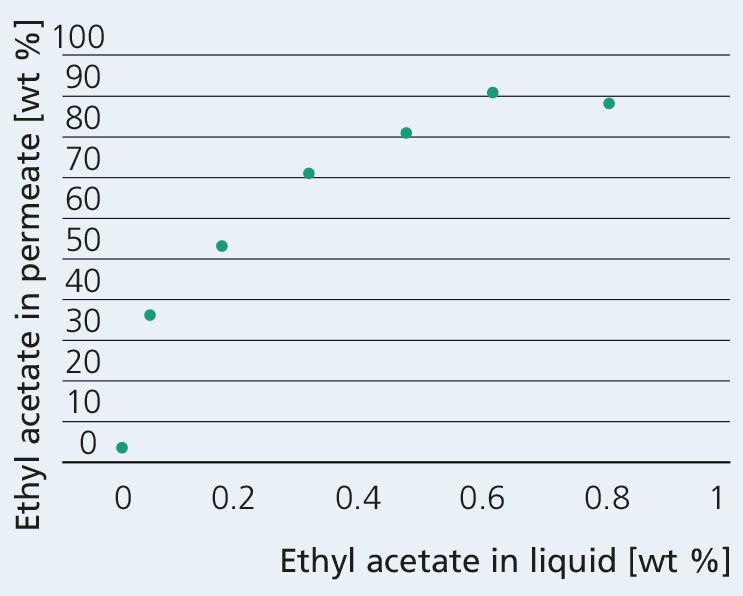

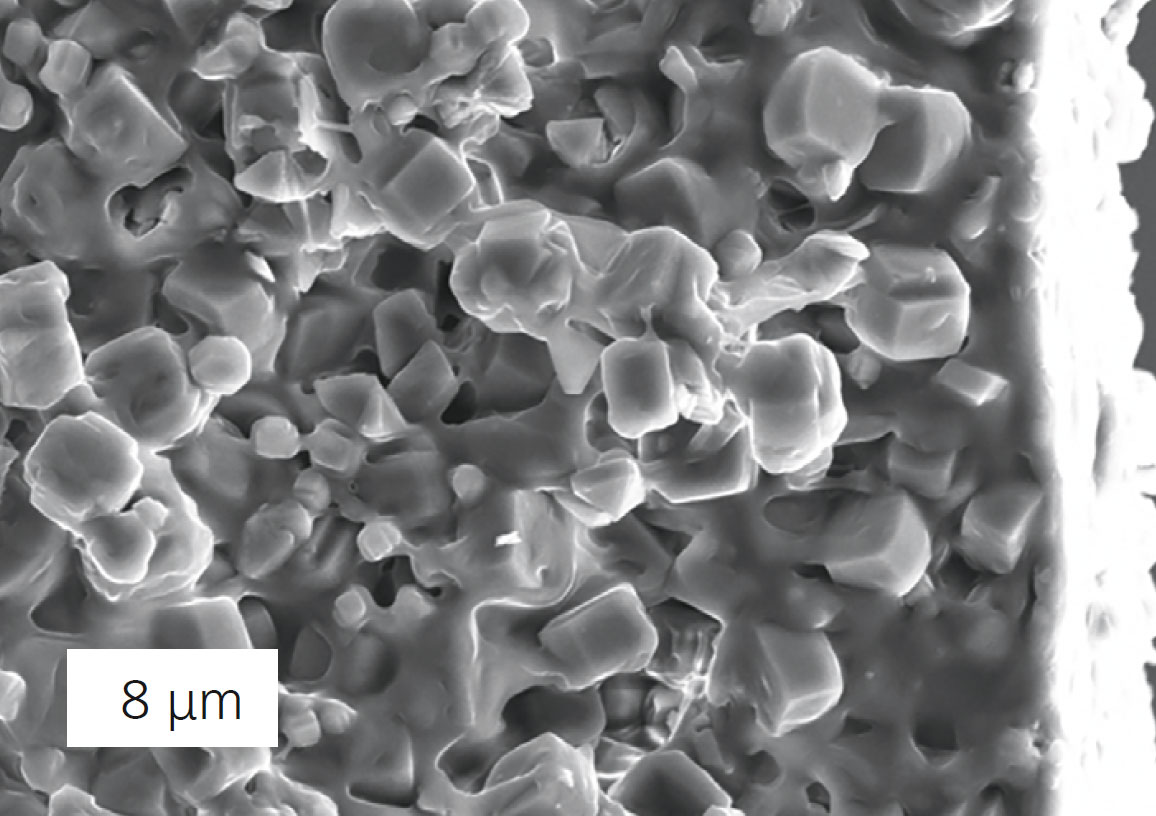

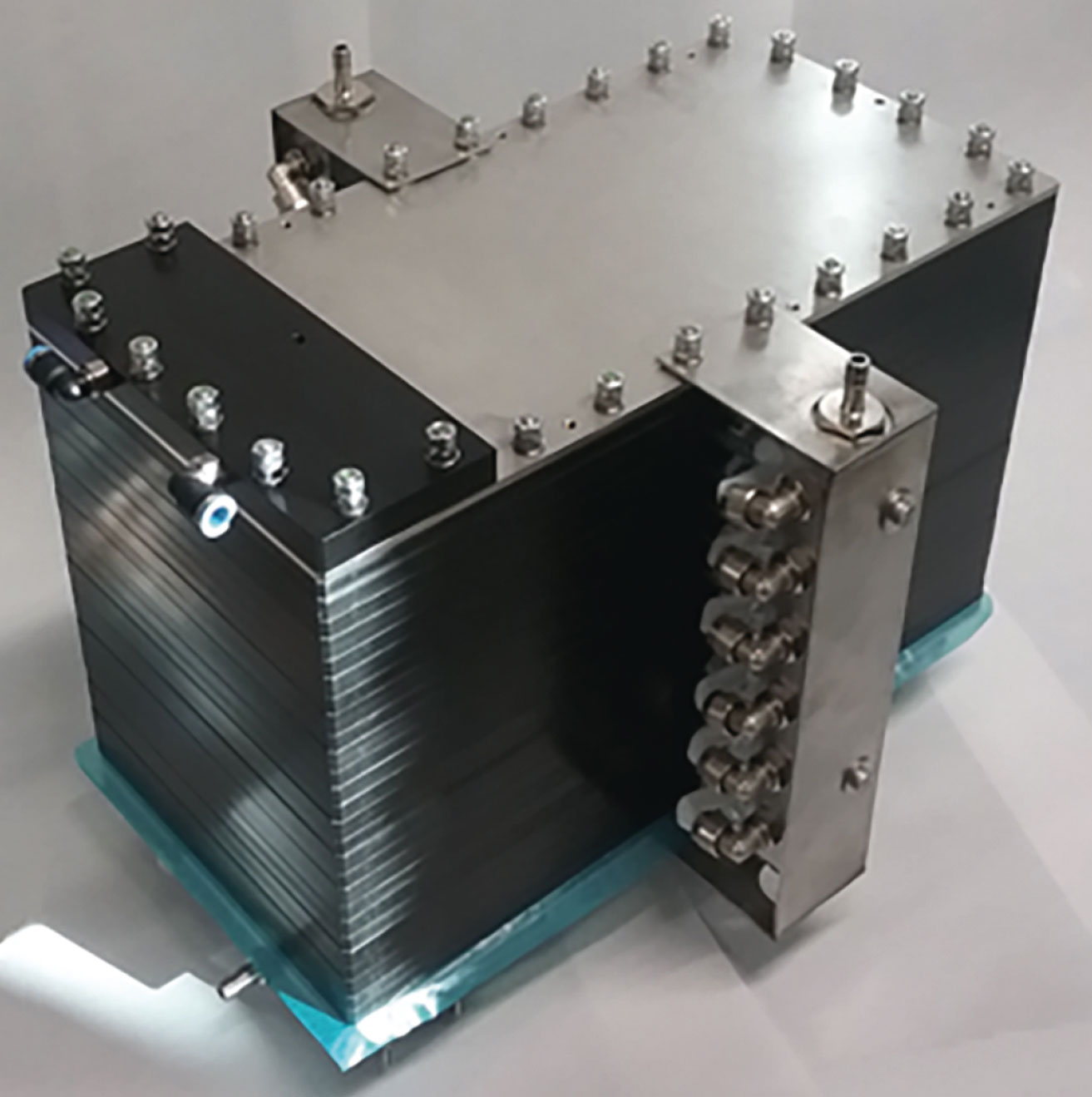

TU Dresden is developing the process of fermentative production of ethyl acetate using the food-grade yeast Kluyveromyces marxianus. With its high volatility, the acetate is stripped from the bioreactor with the exhaust air. The aim is to separate the acetate from this gas flow by means of organophilic membranes. At IKTS, different development types of inorganic membranes and composite membranes are synthesized and tested to separate the ethyl acetate from the exhaust gas. Composite membranes made from zeolite silicalite-1 and silicone rubber show the best separation performance. With these membranes, highly concentrated ethyl acetate is obtained as permeate. Most of the water and inert gases remains in the exhaust gas. In the first attempts to couple the membrane module and the laboratory bioreactor, the ethyl acetate was separated almost completely (94 %) and with a high degree of purity (97.5 %).

The aim of a follow-up project is to develop the technology further. For this purpose, the salt tolerance of the yeasts is to be improved, the membrane area is to be scaled through the development of special membrane modules and the process combination is to be demonstrated on a pilot scale.

Furthermore, the organophilic membranes are tested for the separation of volatile components from other process and exhaust gases.

Services offered

- Customer- and project-specific membrane development and testing

- Delivery of membrane prototypes

- Process testing and development of laboratory and pilot plants

Supported by