In order to meet the global fresh water demand and as a part of integrated environmental protection, desalination processes have become increasingly relevant. However, well-established conventional desalination technologies still have specific limitations: they are not viable for higher salinity levels, they are difficult to customize, require a lot of space and are prone to corrosion. As a hybrid process, membrane distillation (MD) combines the advantages of membrane-based and thermal processes: low sensitivity to high salinity levels, utilization of low-grade energy sources, modest space requirements, modular expandability and the ability to integrate with other technologies. Until now, MD has mainly used polymer membranes. The treatment of high-saline or aggressive aqueous solutions (e.g. abrasive properties, extreme pH, or the presence of solvents) as well as Zero-Liquid-Discharge applications could require the utilization of robust ceramic membrane systems. A potential field of application is for instance the treatment of drainage and waste waters from the petroleum and mining industries.

Functionalization of the membrane surface expands the range of applications of ceramic microfiltration membranes

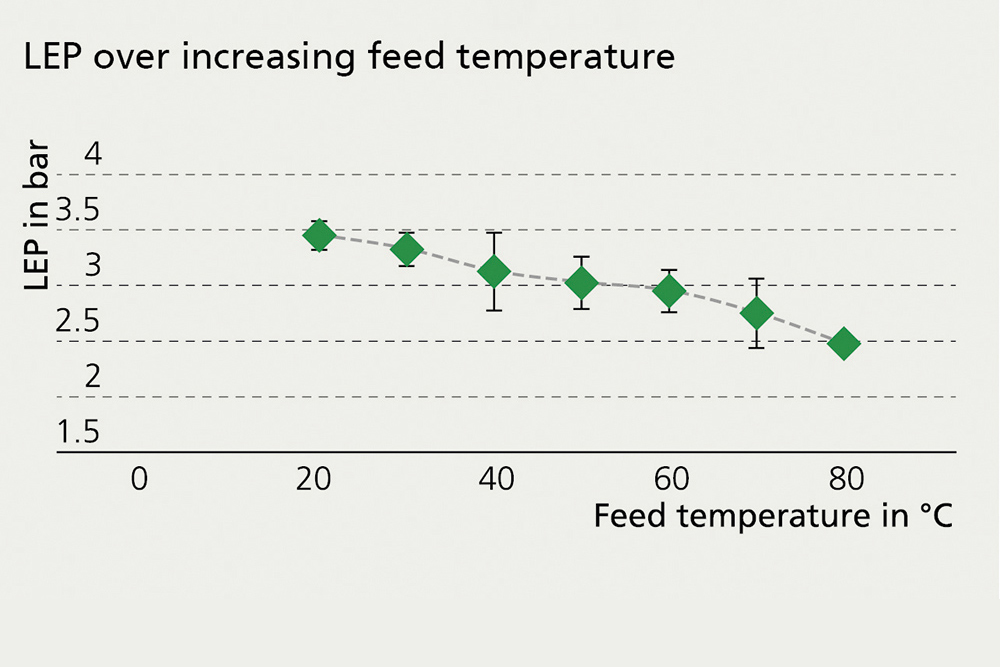

Fraunhofer IKTS uses macroporous ceramic membranes (Al2O3, TiO2, cordierite, mixed oxides) in MD. Their otherwise hydrophilic surface properties were functionalized at IKTS to produce a pronounced hydrophobicity. This ensures that the feed only passes through the membrane in vapor form, not as a liquid phase. The extent and stability of the hydrophobic characteristics are validated by contact angle measurements and liquid entry pressure (LEP) tests. Single- and multichannel tubes were tested successfully in different MD configurations while varying relevant process parameters. For instance, when thin TiO2 single-channel tubes were used, it was possible to determine permeate fluxes of more than 25 kg/(m2h) as well as permeate qualities below

2 µS/cm in a vacuum MD configuration. This makes these robust ceramic membrane systems ideal for separation tasks, for example in aggressive waters with a high salt content.