KeraMOL – cost-efficient ceramic membranes for drinking water supply

Current research

River mill for drinking water

As part of the KeraMOL project, funded by the German Federal Ministry for Economic Affairs and Climate Action (BMWK), mobile drinking water treatment plants shall, in future, supply small and remote locations in Asia, Africa and Central America with water from surface waters. The planned system types are based on the concept of the river mill, where the system itself floats on the water and energy for water treatment and transport is extracted from the river. The system should guarantee a long service life for the filters used and largely do without electronics and chemicals. To meet these requirements, the project combined cost-effectively produced ceramic membranes and a mineral-metal catalyst (MOL®LIK catalyst), which minimizes scaling and fouling effects.

Goal: cost-reduction for energy and materials

Within the KeraMOL project, Fraunhofer IKTS is developing the membrane support and the membrane synthesis for ceramic filter elements. Previous developments were mostly carried out with a view to particularly aggressive operating conditions, which also led to higher unit costs. For the task at hand, the costs for materials and energy needed to be significantly decreased. The costs for membrane support elements (the porous extruded tube) are mainly due to raw materials and sintering. This is what the new development focused on while also bearing in mind that future elements should also be applicable to micro-, ultra- and nanofiltration.

Development steps

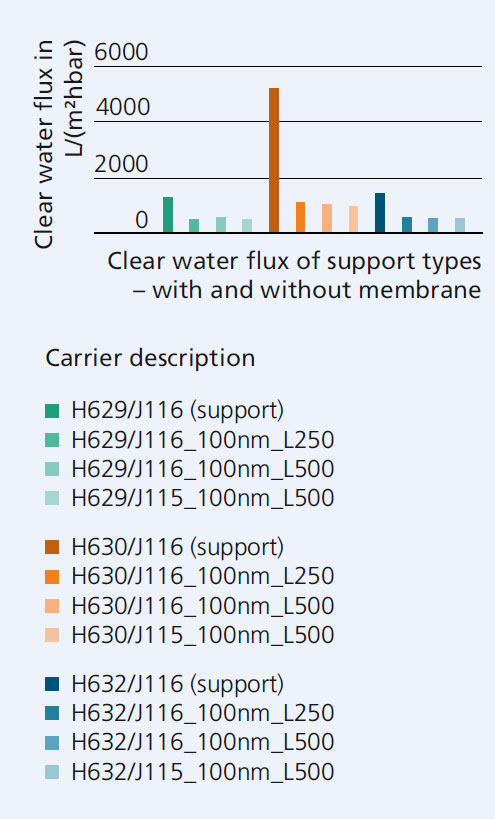

To begin with, a support element was developed based on a tubular single-channel geometry (DA/DI = 10/7 mm). Following the successful development of a low-sintering, coatable support with suitable porosity and high strength, the process was scaled up using the best material system. A 19-channel geometry, an industry-relevant size for tubular filtration elements, was selected for this (outer diameter 25 mm, channel diameter 3.5 mm). Subsequent development steps and the selection of suitable sintering aids finally allowed for a decrease of the firing temperature from 1700 °C to 1430 °C while maintaining surface properties suitable for coating steps. The open porosity is around 30 % and the average pore size (d50) is 3 μm. An Al2O3 membrane layer with an average pore size of 100 nm was synthesized on the support elements. The characterization, which used bubble point, ultrapure water flux and COD retention measurements among others, showed positive filtration qualities. The preferred carrier type in the form of complete filter elements is currently being examined regarding chemical stability. Additionally, project partners are running application tests with regard to operational capability.

The authors would like to thank the German Federal Ministry of Economic Affairs and Climate Action (BMWK) for its funding as part of the “Central Innovation Program for SMEs” (funding no.: ZF4076470SA9).

Sponsored by