Innovative and specialized applications require tailored special pastes and inks, some of which are not available on the market. The Thick-Film Technology group with its focus on functional printing is your experienced and competent development partner. The development process for functional pastes and inks generally includes the following steps, which always take place in close coordination with the client:

Development of client-specific special pastes and inks

Topic

|

|

|

|

|

| Project preparation and definition of requirements | Definition and formulation of raw materials | Manufacturing and characterization of pastes and inks |

Layer manufacturing and characterization | Project completion

|

|

|

|

|

|

Following the development phase, the special pastes and inks are available for application tests with the client and can be purchased from Fraunhofer IKTS after the project has concluded. Manufacturing is compliant with DIN / ISO 9001 / 14001. Technology transfer is a potential alternative.

Project preparation / definition of requirements

Intensive discussion with the client helps to elaborate the target criteria of the pastes or inks to be developed. The main focus is on the functional requirements for the intended use. Other target criteria refer to e.g. the component technologies to be used, such as printing and firing technologies and not least the acceptable cost for the special materials to be developed.

The phase of project development and target criteria definition concludes with an offer for a development job. Once the client has awarded the job, the requirement definitions are once again laid down in detail in a statement of work.

Raw materials and formulation

Depending on the application, special pastes and inks can be developed for various substrate materials (e.g. Al2O3, AlN, Si3N4, ZrO2, steel, glass, LTCC, HTCC or polymer tapes).

The functional layer properties are defined by the targeted compression and interaction of the various inorganic paste and ink components during firing. Furthermore, organic vehicles are selected which influence the printing properties and partly the sintering properties.

The following list contains some, but not all, typical materials for various applications:

Functional materials for

- Conductor pastes: Ag, Au, Pt, Cu, AgPd, AgPt, AgPtPd, W, Mo, C

- Resistor pastes: AgPd, RuO2, Pb2Ru2O6,5, Bi2Ru2O7, BaTiOx, ZnO

- Insulation pastes: glass, glass ceramics, glass-ceramic composite

- Sensor pastes: expansion, temperature (see downloads), pH value (see downloads), ion concentration

Additives for controlling other layer properties, e.g. adhesiveness, temperature resistivity coefficient:

- MnO2, Cu2O, Bi2O3, CoAl2O4, ZnO, SnO2, Fe2O3, Cr2O3, Mn2O3, RuO2, CoO, Co3O4

Glasses

(see downloads) for adhesion/bonding and improved stability, e.g.:

- Pb- and Bi-free or -containing glasses, glass ceramics, glass-ceramic composites

Organic vehicles for processibility in the thick-film process (e.g. printability, burn-out behavior):

- Organic solvents, phthalate-free plasticizers, wetting agents, thixotropic agents

- Cellulose-based polymers, polyacryclates

Manufacturing and characterization of pastes and inks

It is not just the properties of the raw materials that determine the resulting processibility of the pastes and inks (for printing, thermal processes) and the functional performance of the resulting processed layers; the way the substances are mixed with each other, i.e. dispersed, plays a significant role as well. The Thick-Film Technology group with its focus on functional printing has a wealth of experience and the proper equipment for the manufacturing of functional pastes and inks. This includes, among other things:

Glass manufacturing

- Creation of mixtures, melt

- Characterization: density, glass transition temperature (Tg), dilatometric parameters/softening point, hot stage microscopy, grain size distribution

Powder preparation

- Grinding with/without grinding aids, tempering in various types of atmosphere, manufacture of powder mixtures

- Characterization: specific surface (BET model) or grain size analysis, sintering behavior and thermomechanical analysis and hot stage microscopy

Dispersing

- Dissolver, planetary mixer, speed mixer, mortar grinder, tumble mixer, tumbling mill

- Three roll mill

Characterization of rheological parameters of pastes and inks (cone-and-plate, plate-and-plate, cylinder-and-cup, and capillary rheometer, temperatures from -20 °C to +150 °C)

- Shearing load-dependent rheological behavior (10-3…105 s-1)

- Time-dependent rheological behavior, relaxation

- Examination in rotation or oscillation

Layer manufacturing and characterization

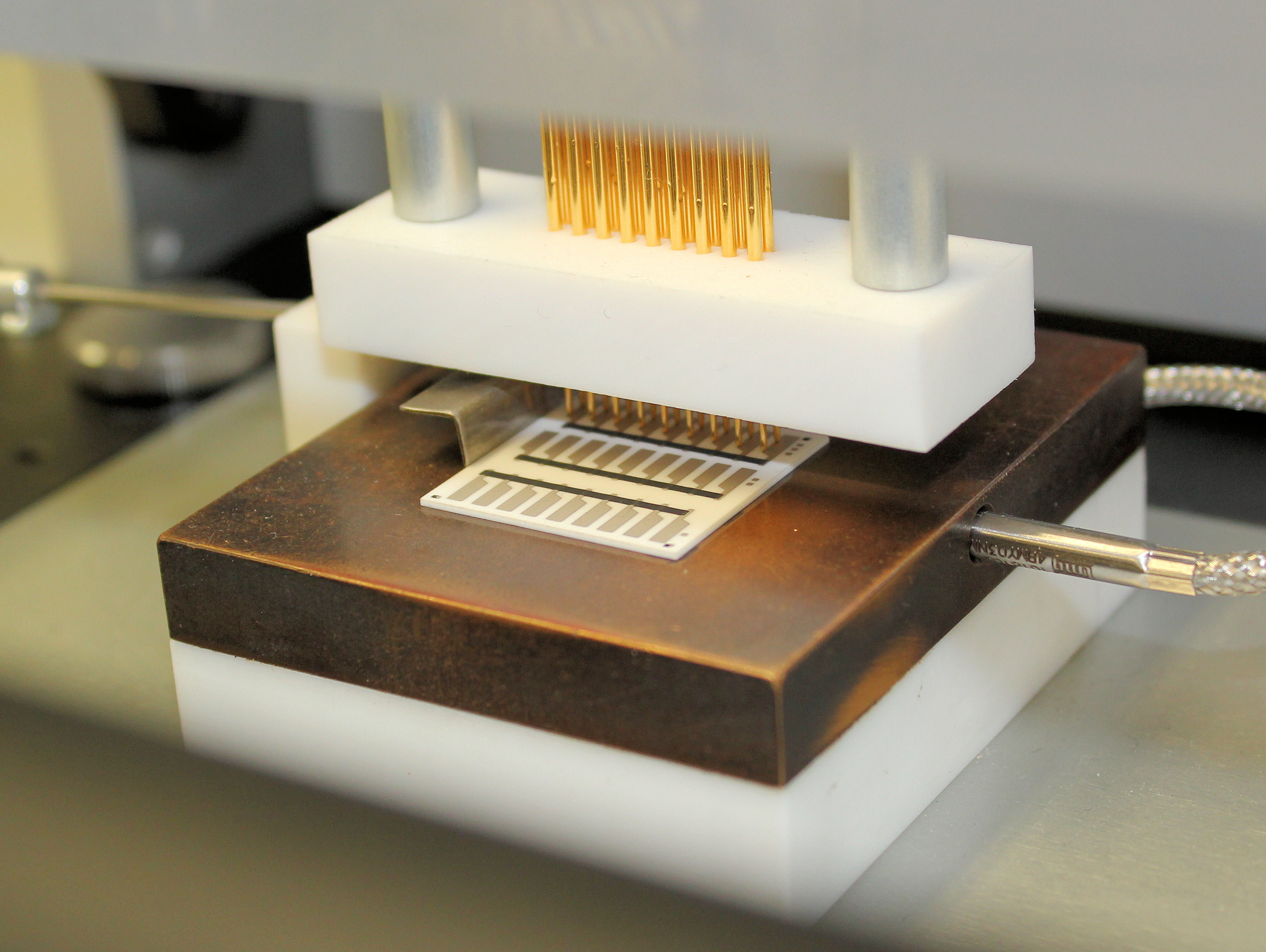

A comprehensive range of equipment is available to manufacture the required functional layers (various printing and firing technologies), used in line with the client requirements. Some of the printing technologies available are screen printing (planar, tubular, hot-melt) or aerosol-jet, ink-jet, gravure, dispense and dispense-jet printing (see Downloads).

All relevant functions are determined and collated with the target criteria defined in the statement of work in the context of the subsequent layer characterization, which takes place in accordance with DIN 41850. For this purpose, numerous geometric, mechanical and electric variables are routinely determined following firing, in order to verify and optimize the tailored properties targeted.

The Thick-Film Technology group with its focus on functional printing has a large number of measuring stations and equipment available to achieve this. In addition to the standard tests (coat thickness, roughness, temperature-dependent resistance, suitability for soldering, etc.), specific process effects (e.g. variations in firing, screen-printing tolerance values) can also be examined and modified in order to be able to represent the effect on the resulting layer properties.

Electric properties

Mechanical properties – in particular of conductor pastes

Geometric and mixture properties

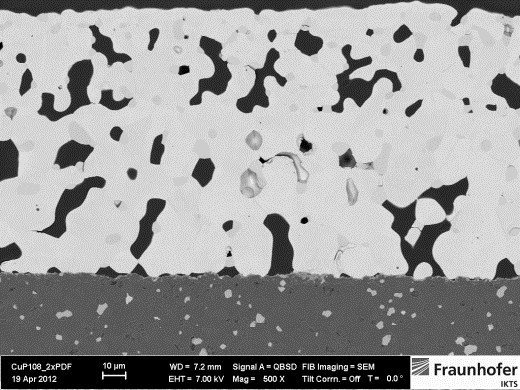

- Optical and mechanical sample scanning, as well as light and electron microscopy

- Measuring and characterization of coat thicknesses and widths (aspect ratio), coat thickness homogeneity (roughness)

- Determination of microstructure and phase composition