Thick-printed copper pastes for power electronics

Current research

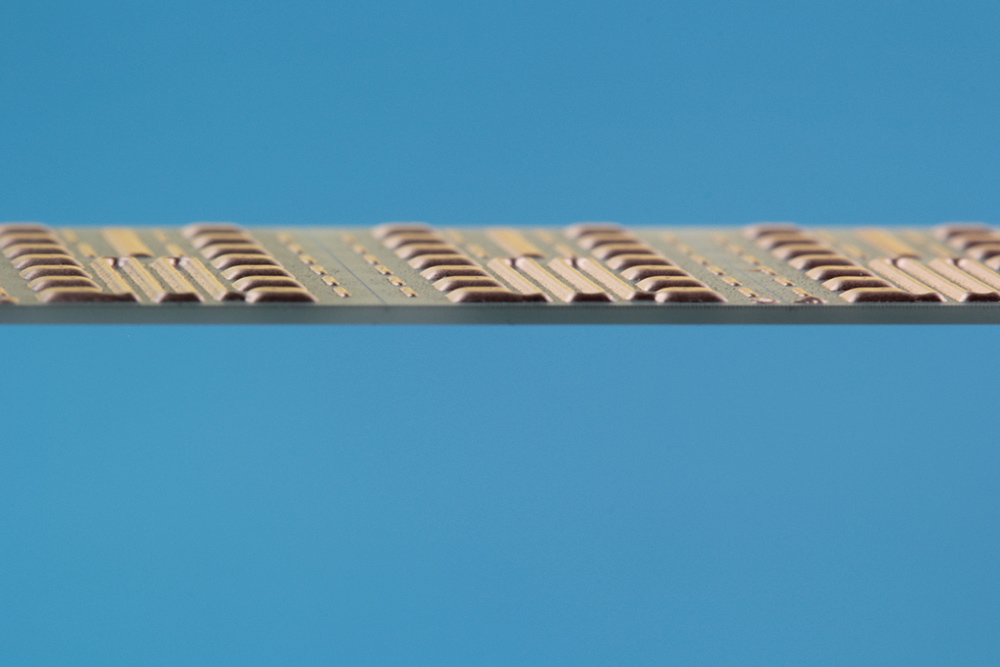

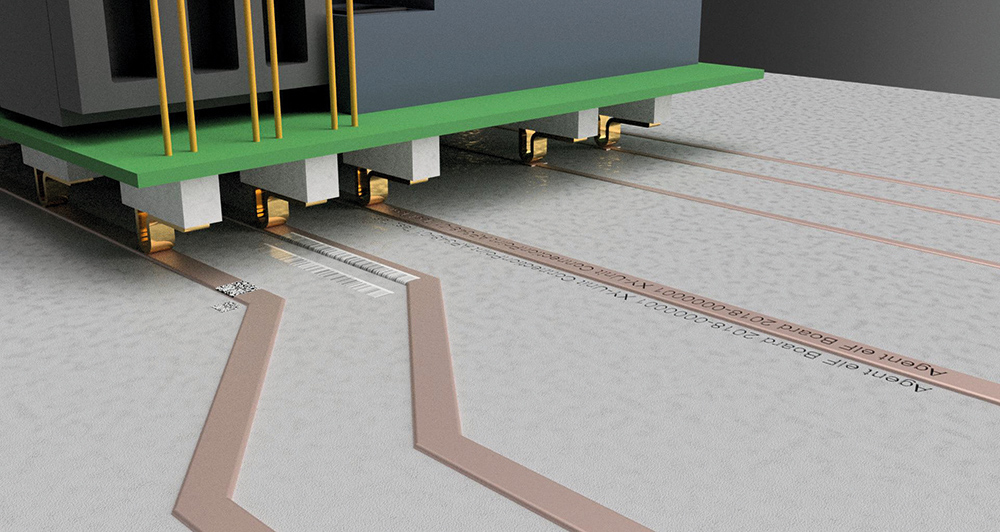

Power electronic systems are the backbone of the supply infrastructure of renewable energies and electromobility. Modules in which power semiconductors and other components are integrated form the central components of such systems. However, the DCB (direct copper bond) substrate used in the majority of power modules limits the integration density of power modules. As a result, copper thick-film systems are currently being increasingly used in this field. Copper paste systems for substrate types, such as Al2O3 and AlN, have been successfully developed at Fraunhofer IKTS. Scientists have realized copper layers with up to 300 μm film thickness, which are deposited by screen or stencil printing (Figure 1). They allow finer structuring with a higher design flexibility than commercially available DCB substrates and show a higher degree of robustness under thermal cycling stresses. However, in order to achieve multilayer structures on ceramic substrates, the development of further paste systems, such as conductive and dielectric pastes, is needed. The development of such paste systems for the high-temperature (650 to 950 °C) and low-temperature (200 to 280 °C) ranges was also realized at IKTS. Above all, the challenge was to match the developed pastes to the copper ceramic substrate, in which the sintering under nitrogen atmosphere is a basic requirement. These novel IKTS developments will, in the future, make the production of power modules more compact, functional and cost-efficient. Over the past two years, these paste systems have been enhanced with respect to digital 3D printing technologies. In the BMBF-funded project “Agent elF” (additive manufacturing for the integration of electronic functionalities), a printed control panel was realized in cooperation with numerous project partners, such as Siemens. The manufacture of classic control panels involves the integration of wiring harnesses for the electrical connection between control systems and peripheral components. This process is currently associated with a high manual effort and low potential for innovation. The construction of printed conductor and insulation layers on a carrier plate (backplane) of the control panel and thus the realization of individual product backplanes eliminates the enormous manual effort and opens up a wide application potential when it comes to electrically connecting complex circuit systems. Part of the project inolved developing 3D-printable copper conductive and insulating pastes for dispensing technology. Figure 2 shows a section of a backplane with a power electronic component developed in the project for demonstration. The ground plate consists of a spinel-coated steel, which combines high-current and signal tracks with copper pastes to form a complex control cabinet module.

Download

Supported by