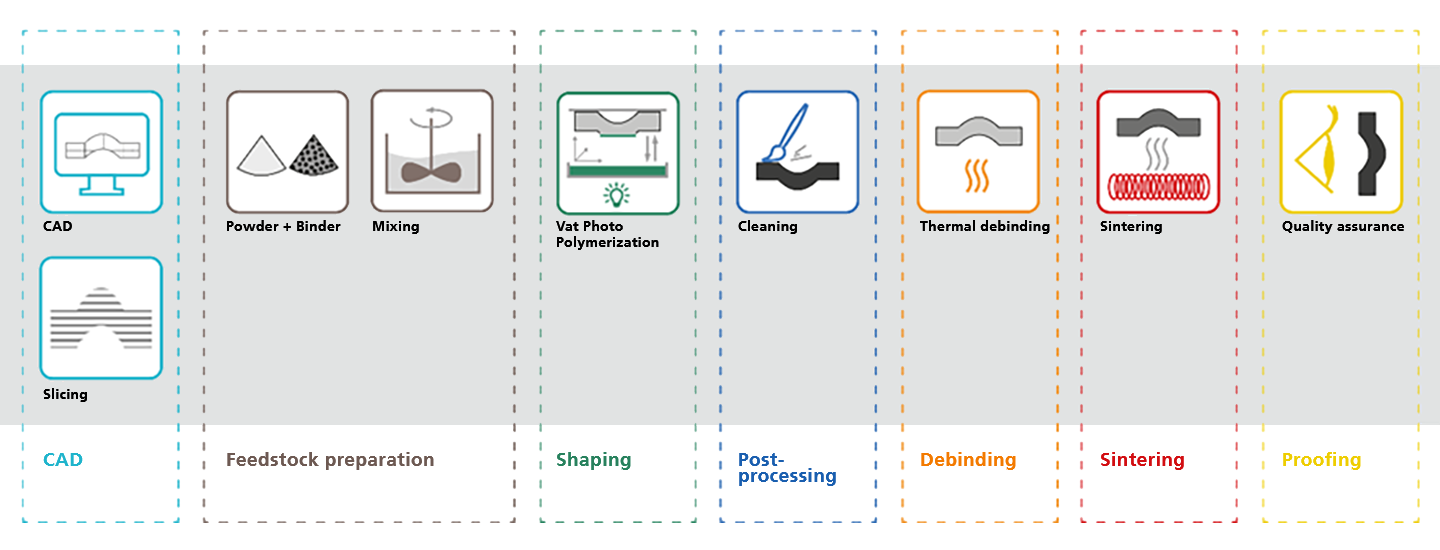

The process, which was specially developed for the additive manufacturing of ceramics, works according to the DLP principle. We use the CerFab7500 and CeraFab 8500 systems from Lithoz GmbH for this purpose. The technology is based on the principle of stereolithography, i.e. organic suspensions highly filled with ceramic powder particles are solidified layer by layer by irradiation with light of a defined wavelength. The exposure takes place by means of DLP module, whereby all areas of a layer to be consolidated are cross-linked simultaneously.

We have summarized an overview of the available material systems, technical equipment as well as our range of services in the field of Vat photopolymerization in our industrial solutions.