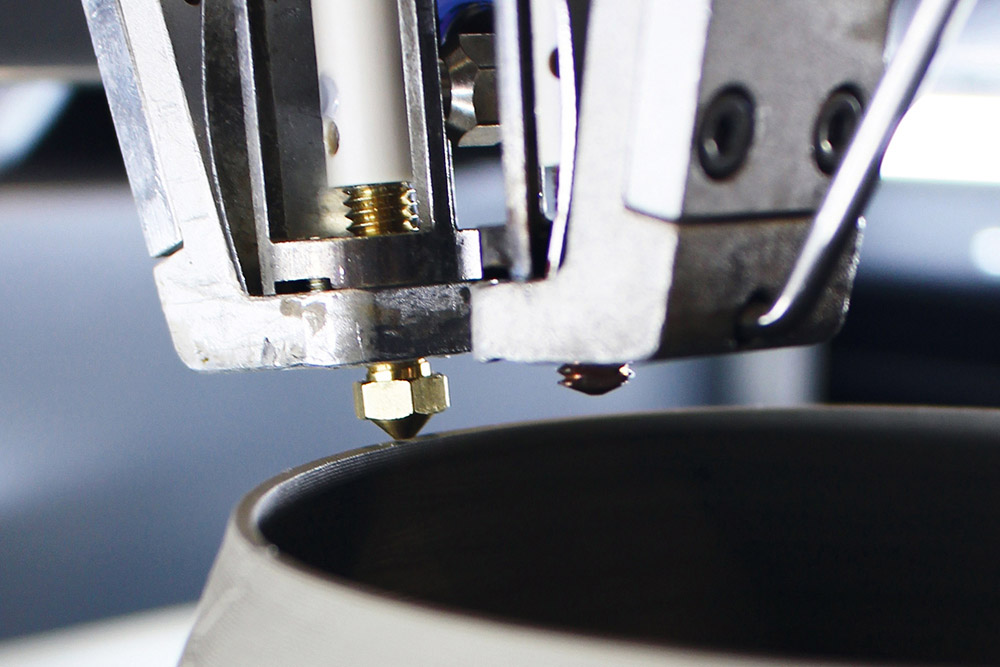

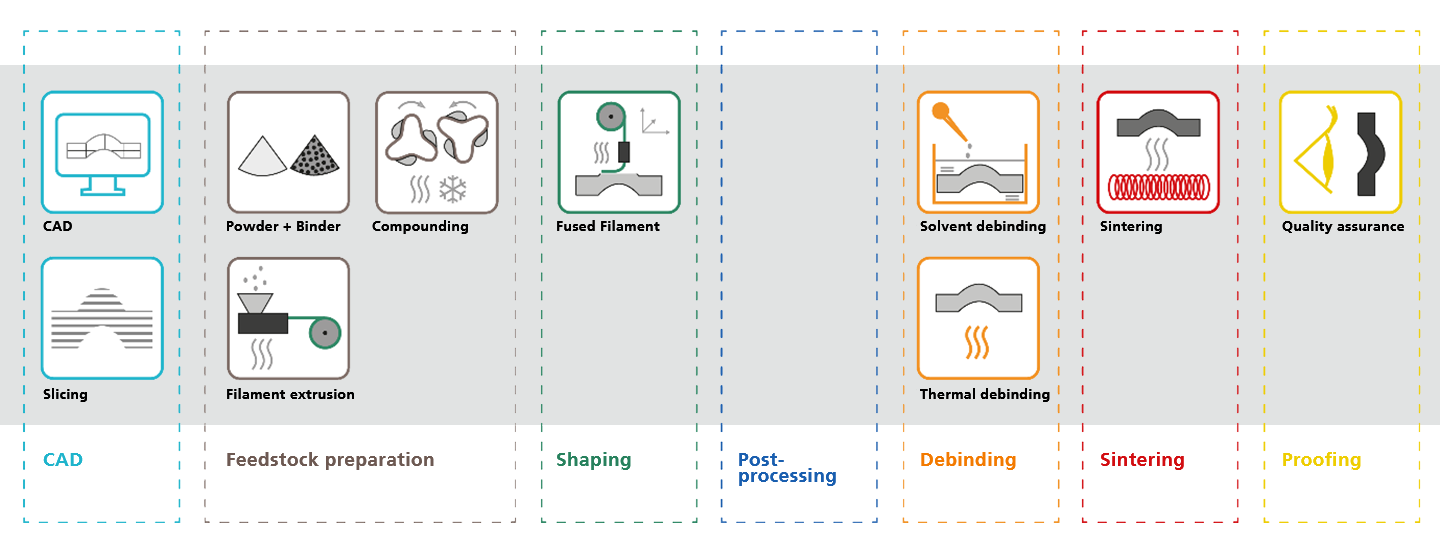

Fused Filament Fabrication (CerAM FFF) uses homogeneous, highly filled thermoplastic materials. The process convinces with a large installation space, a high productivity, a large variety of materials, the possibility of a multi-material construction as well as the low acquisition costs for the necessary equipment.

We have summarized an overview of the available material systems, technical equipment as well as our range of services in the area of CerAM FFF in our industrial solutions.