CerAMfacturing: electrically conductive and insulating Si3N4-SiC-MoSi2 multi-material parts

Current research

Additive manufacturing (AM) of functional components

In order to meet the ever-increasing demands for the functionalization and miniaturization of components, it is necessary to combine different materials in components with highly complex geometries. Property combinations such as dense/porous or electrically or thermally conductive and insulating in additively manufactured components enable the production of parts with previously unattained properties. AM technologies based on thermoplastic binder systems, in which the materials are applied only at the points at which they are needed, are particularly suitable for the production of multi-material components. These AM technologies also offer the chance to process an almost unlimited materials portfolio.

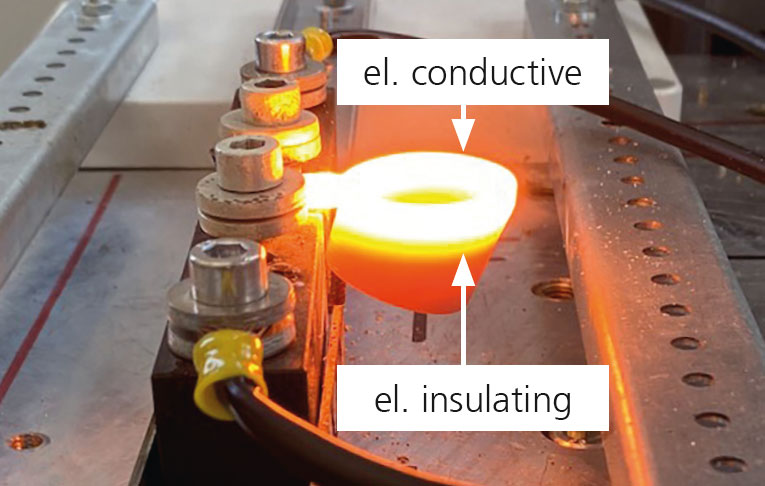

Electrically conductive and insulating properties in one component

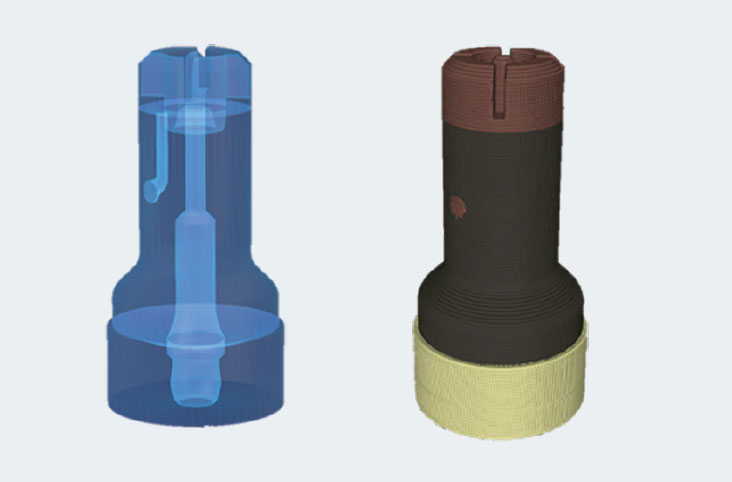

Electrically conductive silicon nitride is a high-temperature-stable mixed ceramic. It consists of silicon nitride (Si3N4), an oxide grain boundary phase and one or more electrically conductive components. These can be TiN, SiC and various metal silicides. Because of the special nature of the material structure, even minor changes in composition are enough to make a material conductive or non-conductive. The combination of Si3N4-SiC-MoSi2 makes it possible to realize complex ceramic sensors, heaters, and igniters, within one manufacturing step, which can be used at temperatures above 1000 °C (Figures 1–3). At Fraunhofer IKTS, various AM technologies are available for this.

Process diversity at Fraunhofer IKTS

Multi Material Jetting (CerAM MMJ) is a droplet-based AM technology developed at IKTS that enables the manufacturing of components from one or more materials simultaneously by fusing individual thermoplastic droplets. Highly particle-filled thermoplastic feedstocks are deposited in the molten state. The technology is currently being commercialized in the form of an Fraunhofer IKTS spin-off within the framework of an Exist research grant project (03EFQSN180) of the BMWK. Starting 2023, the spin-off – AMAREA Technology GmbH – will enter the market as system provider for MMJ 3D printers and associated printing materials and services.

Fused Filament Fabrication (CerAM FFF) relies online-based material application. The material is fed in the form of continuous filaments (developed at IKTS) with a wide variety of sintered materials used for particle filling. The existing system technology has a dual print head and thus also offers the possibility of manufacturing multi-functional components.

Services offered

- Component development (design and shaping based on different AM technologies and materials

- Customized filament development and distribution for CerAM FFF

Sponsored by