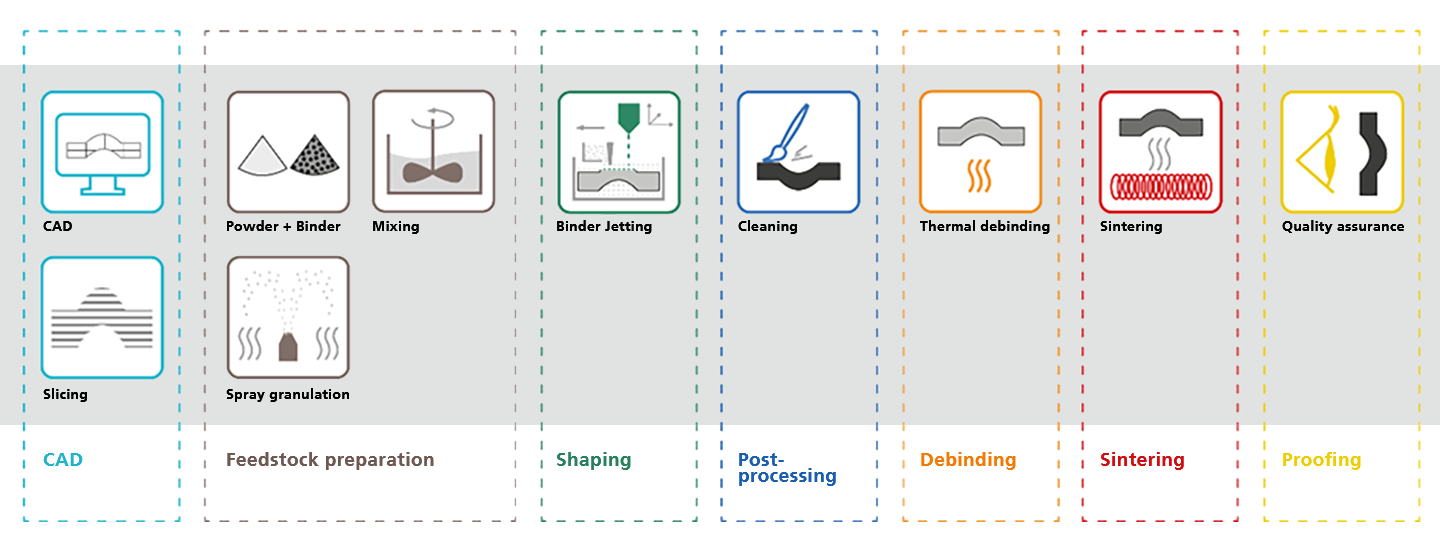

One of the most productive additive manufacturing processes is binder jetting (CerAM BJT). The powder-based process is characterized by the production of large-volume components or the simultaneous production of numerous smaller components. For this purpose, powder is applied layer by layer over a construction field and locally bonded by means of a print head. This bonding is usually based on an organic, which is added to the printing liquid or the powder.

We have summarized an overview of the available material systems, technical equipment as well as our range of services in the area of CerAM BJT in our industrial solutions.