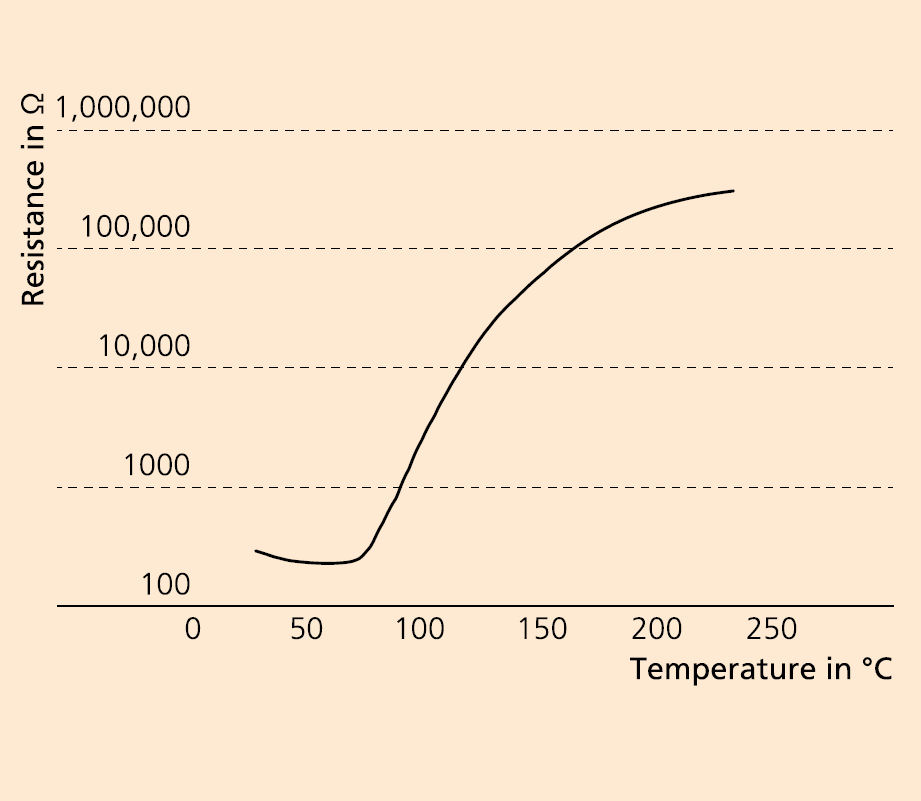

PTC heating elements (positive temperature coefficient) are used in large quantities in automotive supply air heaters or as heaters for household appliances. They can be characterized by special resistance-temperature properties, which show a sharp increase of electrical resistance within a narrowly defined temperature range. Compared with NTC heaters (negative temperature coefficient), they offer the advantage of being self-regulating, which means that no additional temperature regulation and over-temperature protection equipment is needed. Due to their typical design (mostly pins, platelets, rings and honey combs), PTC elements provide a very poor thermal transfer to the medium that needs to be heated. To compensate for this, they have to be combined with metal heat exchangers.

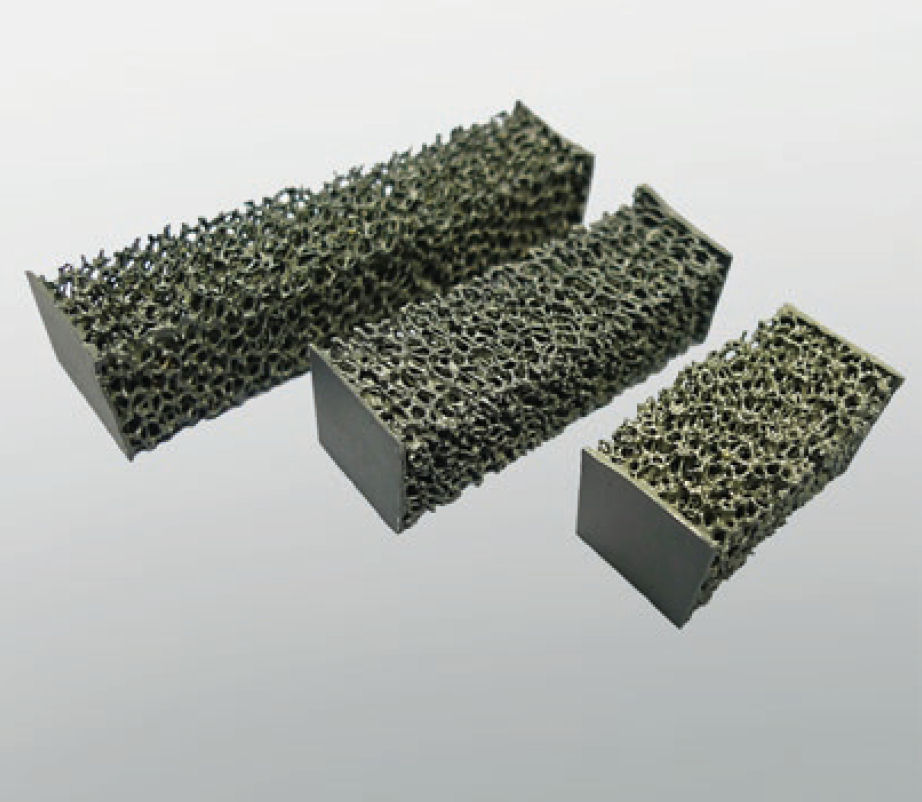

Fraunhofer IKTS has developed ceramic foams based on leaded and unleaded barium titanate powders with transition temperatures of 45 °C, 100 °C and 120 °C. Their cellular structure provides large geometrical surfaces and, thus, strong heat transfer to the medium to be heated. The media – such as gases or liquids – can flow through the heater structure directly and in every direction, resulting in a particularly effective heat transfer as well as swift and precise temperature control. Thanks to this direct contact, additional heat exchangers are no longer needed, which enables especially compact heaters. The construction of the foam ceramics as a sandwich structure (Figure 1) allows for easy electrical contacting – simple and customizable in production and therefore profitable even in small series. The components developed by IKTS were examined with a standard testing method according to DIN EN 60738-1 (06/2010). The tests did not show any significant changes of electrical resistance after 1000 and 50,000 cycles of operation in cold atmosphere and at room temperature; the specimens showed the same good behavior in permanent operation (1000 h), with the highest operating temperature at 70 °C and under an operating voltage of 30 V. Furthermore, IKTS developed an after-coating process for the foam structure using epoxy resin. This makes the ceramic material inert when in contact with circulating media, avoiding the penetration of PTC material into the media in the event of mechanical damage done to the foam structure – an essential requirement for medical applications, such as intravenous drips.

Services offered

- Development and synthesis of doped leaded and unleaded barium titanate powders with different transition temperatures

- Development of foam ceramics with PTC and NTC behavior

- Evaluation of electrical properties and standard testing in accordance with DIN

- After-coating of foam structures with resins or active components (e.g. catalysts)

- Manufacturing and analysis of prototypes and small series