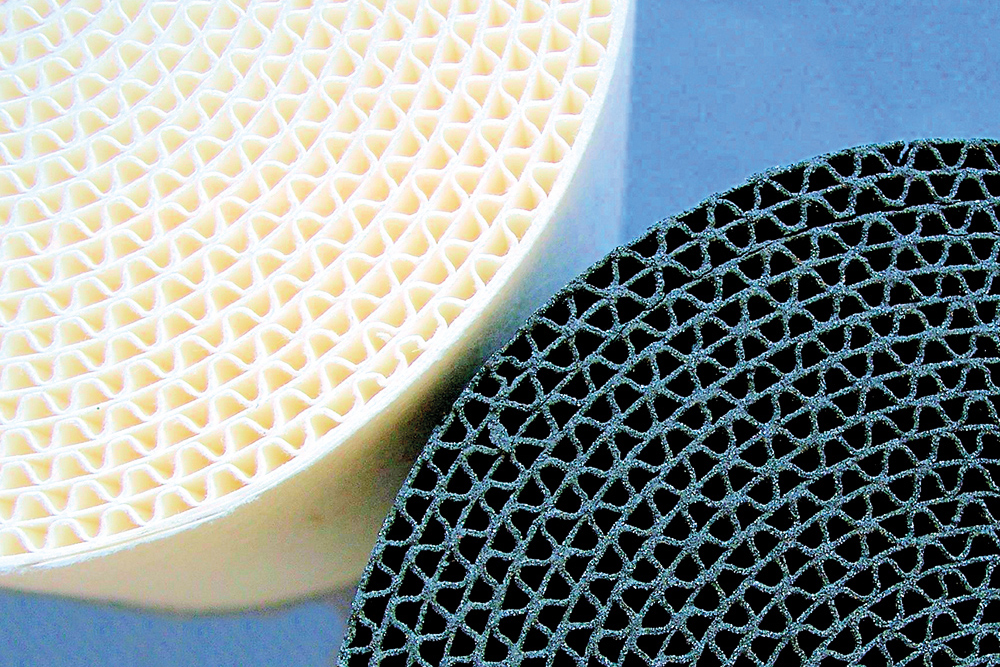

In many applications, components are subject to axial or allround compressive loads. Catalytic converters or particle filters, which are pressed into metal cannings in combination with high-temperature resistant sealing mats, are an example of this. Knowledge of the mechanical behavior of the complex and often filigree components under the compressive stresses is often essential for the design and layout of the overall systems. Determining reproducible and comparable mechanical characteristic values for these types of stress represents a major challenge for measurement technology.

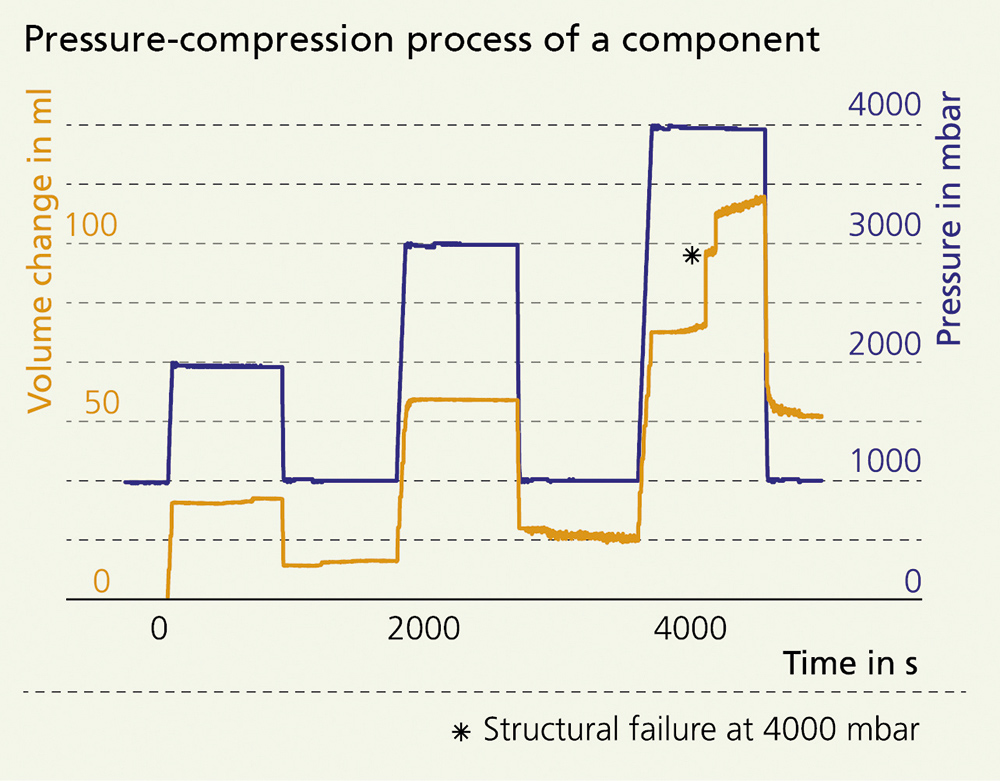

Fraunhofer IKTS has adapted an isostatic pressure test stand for such questions, with which the component compression can be measured inline. The component, which is sealed and embedded in an incompressible fluid, is subjected to specific pressures and temperatures. The resulting deformation of the component leads to a reduction in the fluid level, which is measured capacitively during the test. The programming of pressure ramps and cycles enables implementing extensive test routines from which conclusions can be drawn about creep properties, elastic-plastic deformation behavior, and even the fracturing properties of the tested components (diagram).

The test bench can be used for a wide range of applications thanks to its advanced options for documenting real-time videos and carrying out vacuum tests. The applications range from classical pressure and tightness tests to the characterization of volume shrinkage during the consolidation of reactive resins.

Services offered

- Isostatic pressure testing of components, in particular filters and catalysts with following conditions:

Component size up to: Ø = 360 mm; h = 270 mm

Pressure: 0–10 bar

Temperature: up to 250 °C

- Development of application-specific pressure ramps and cycles for the in-line measurement of volume changes to evaluate component elasticity, creeping and failure processes