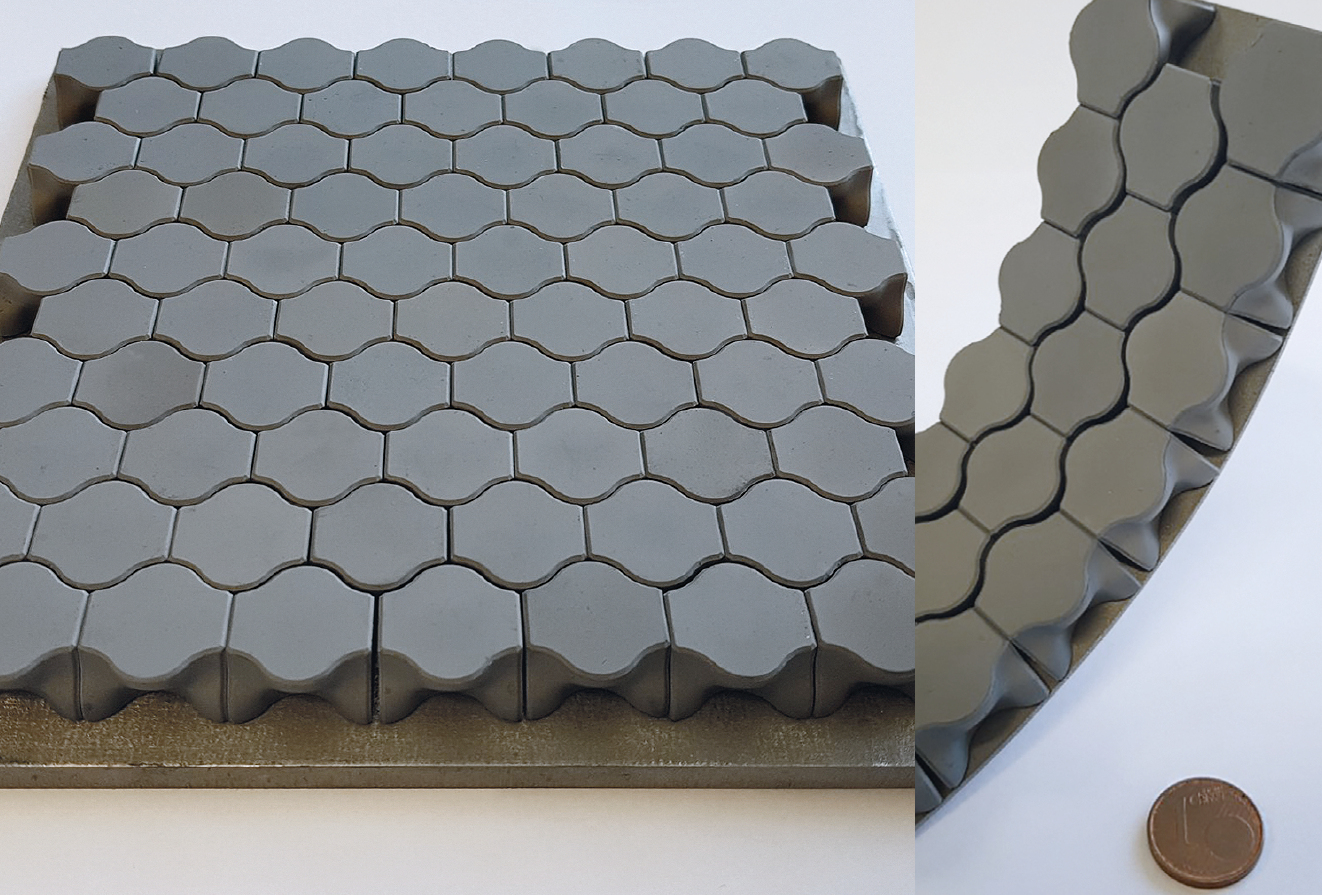

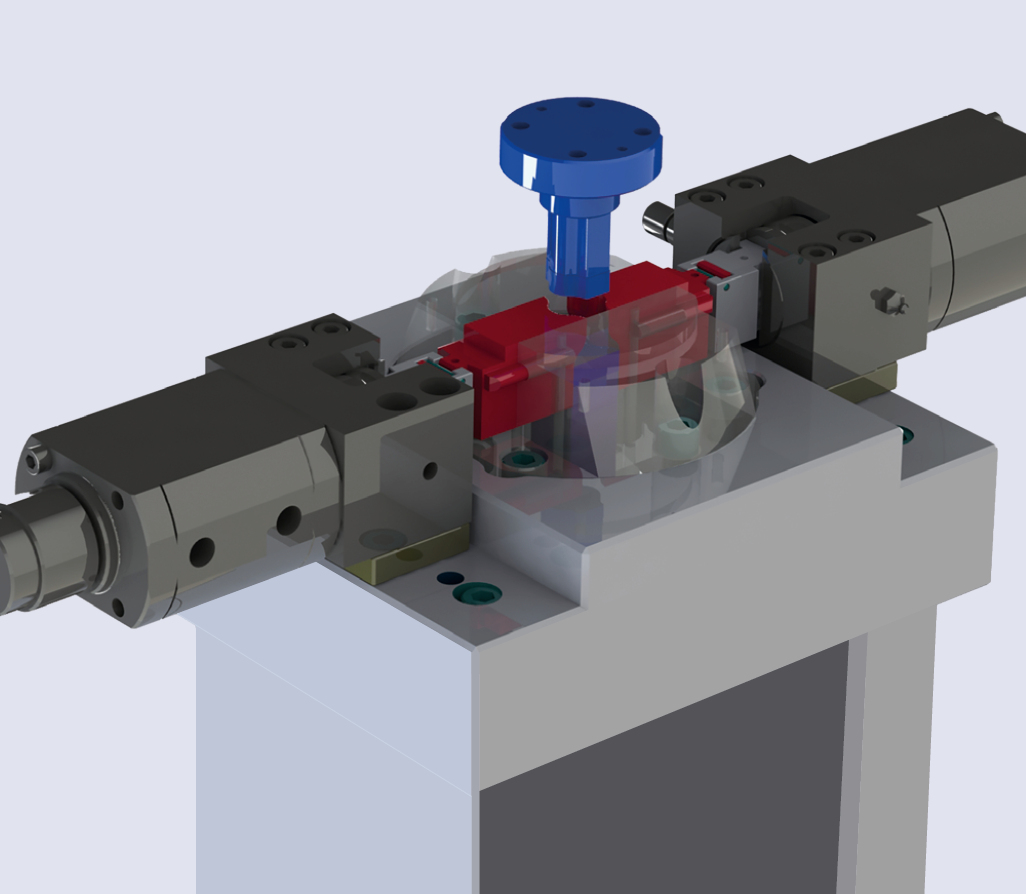

Today, protection methods for high dynamically stressed components in mechanical, plant and automotive engineering involve either high weight (metals) or limited formability (ceramics). Currently, no composite material exists which combines the excellent properties of both material groups, such as maximal strength with good ductility. With the new ceramic components developed at Fraunhofer IKTS, based on concepts of “topological interlocking” [*], in combination with cost-efficient brazing or bonding technologies, complex steel surfaces can be equipped now with ductile ceramic armoring (DuktAr), and thus innovative 3D protection methods can be realized. These methods can be implemented, for instance, in protective devices of centrifuges, rotors, recycling plants, or in high-speed cutting. With their unique geometry, the ceramic components are particularly advantageous, since they can be assembled to areas of variable sizes, very much like puzzle pieces, thus maximizing the freedom of design. In addition to developing a suitable ceramic-compatible geometric design, IKTS has established a novel pressing technology, in which the DuktAr parts can be manufactured in one single step – cost-efficiently and without the need for subsequent mechanical machining. A new pressing die was developed for this purpose, which was integrated into an existing pressing device. Contrary to classic setups with vertical punches, the new tool includes two additional horizontal cross punches. They are positioned at an angle of 180° where their surfaces map the needed 3D contour. The cross punches operate hydraulically. During the manufacturing of the pressing parts, the punches are in the front position, forming a closed polygon course with the die. Then they move to the rear position to expose and remove the pieces. The automatic mode allows to produce 5–10 pieces per minute. So far, component series made of silicon carbide and alumina were pressed and sintered using this technology. The finished DuktAr pieces were then brazed or bonded on the metal sheet surface. Subsequently, their shear strength was measured to evaluate the composite quality. Soft solder joints reached values of 18 MPa, adhesive bonds even 40 MPa.

[*] Dyskin, A. V., Estrin, Y., Kanel-Belov, A. J. & Pasternak, E. Toughening by Fragmentation - How Topology Helps. Adv. Eng. Mater. 3, 885-888 (2001).

Services offered

- Development and manufacturing of 3D ceramic parts made of different ceramic materials for the reinforcement of metal surfaces as protective lining

- Development of joining technologies for metals and ceramics by brazing or bonding

- Manufacturing of prototype parts

The “DuktAr“ project (funding number 601 039) was funded by an internal Fraunhofer program.