Thermophysical properties of hardmetals as a function of microstructure

Current research

Tungsten carbide-cobalt hardmetals (WC-Co) have high hardness and good fracture toughness and are therefore widely used as cutting tool materials. The requirements for such tools increase with higher cutting speeds or the increasing share of hard-to-cut materials. In addition to mechanical properties, other properties, such as the thermal conductivity of the tool material, are of particular importance because high temperatures occur locally during the cutting process.

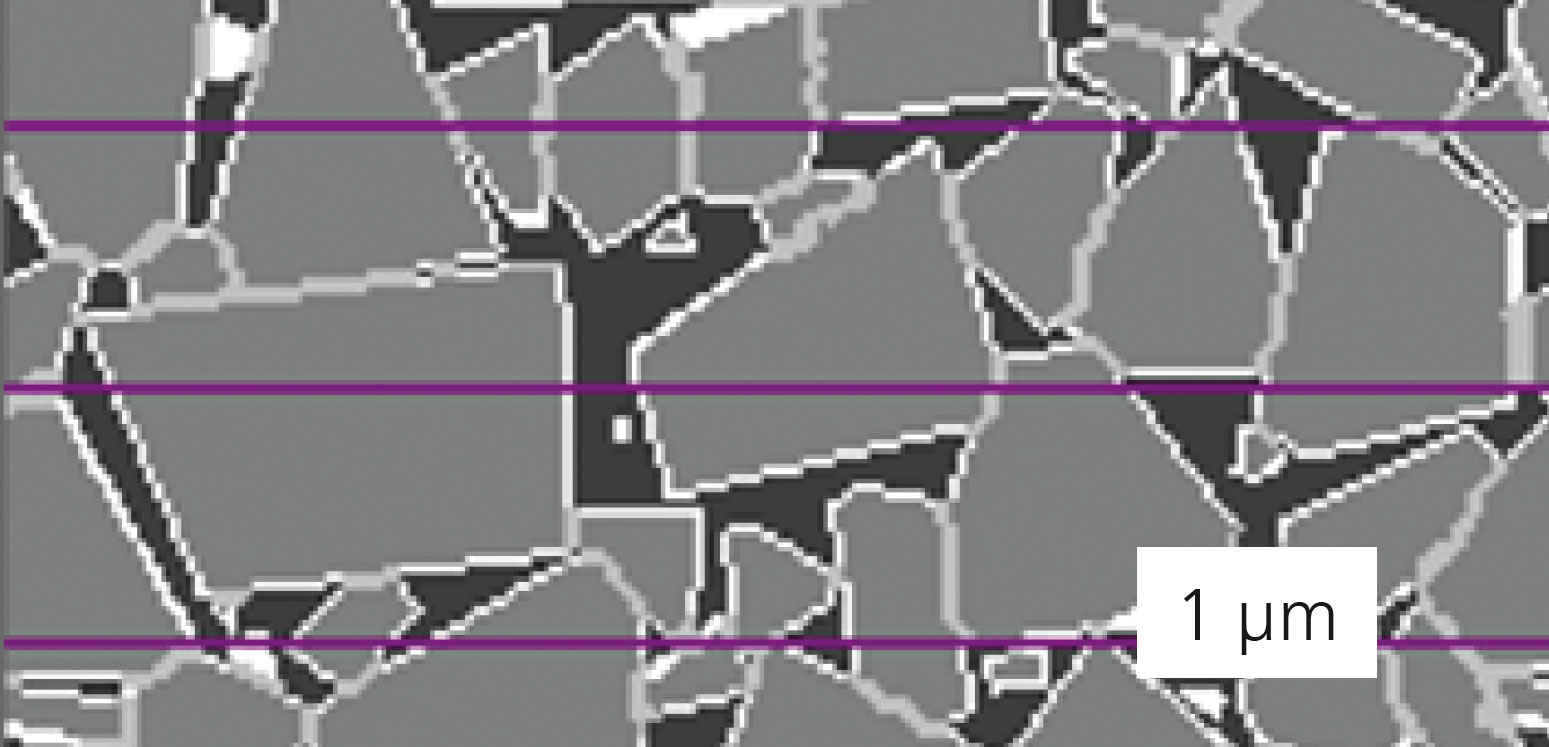

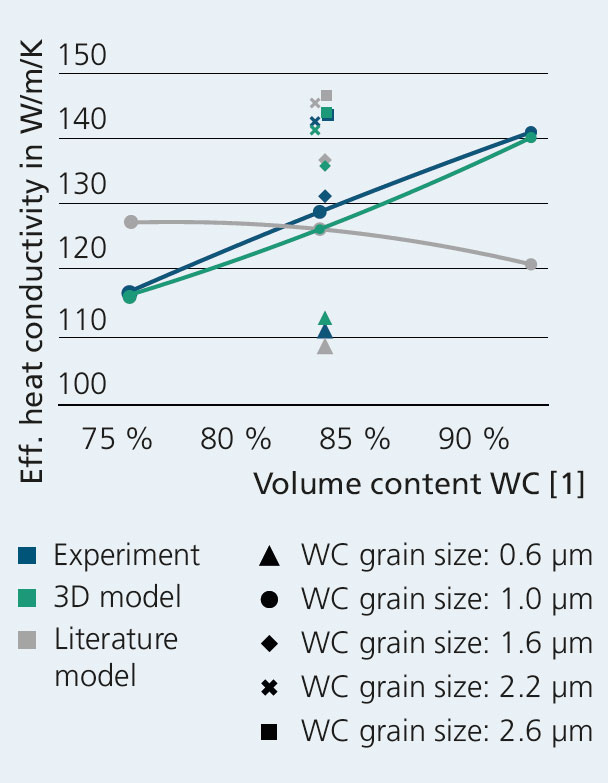

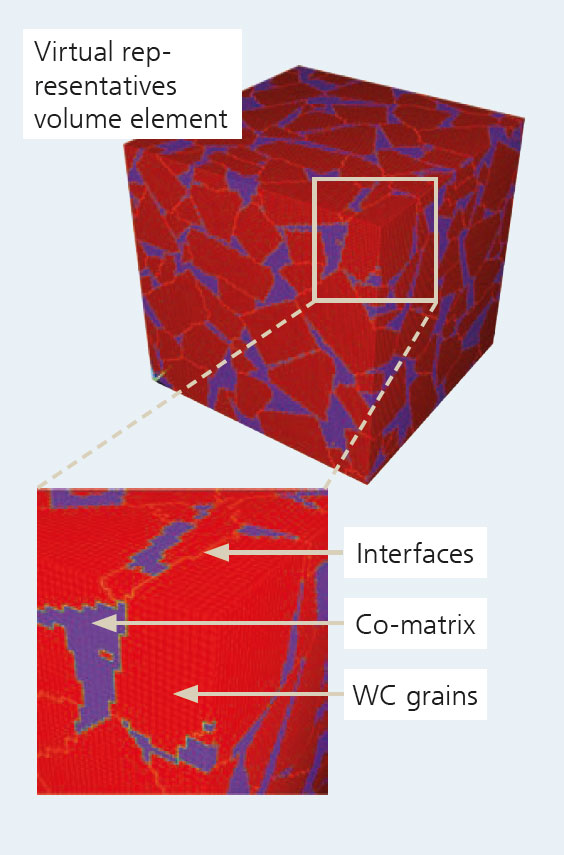

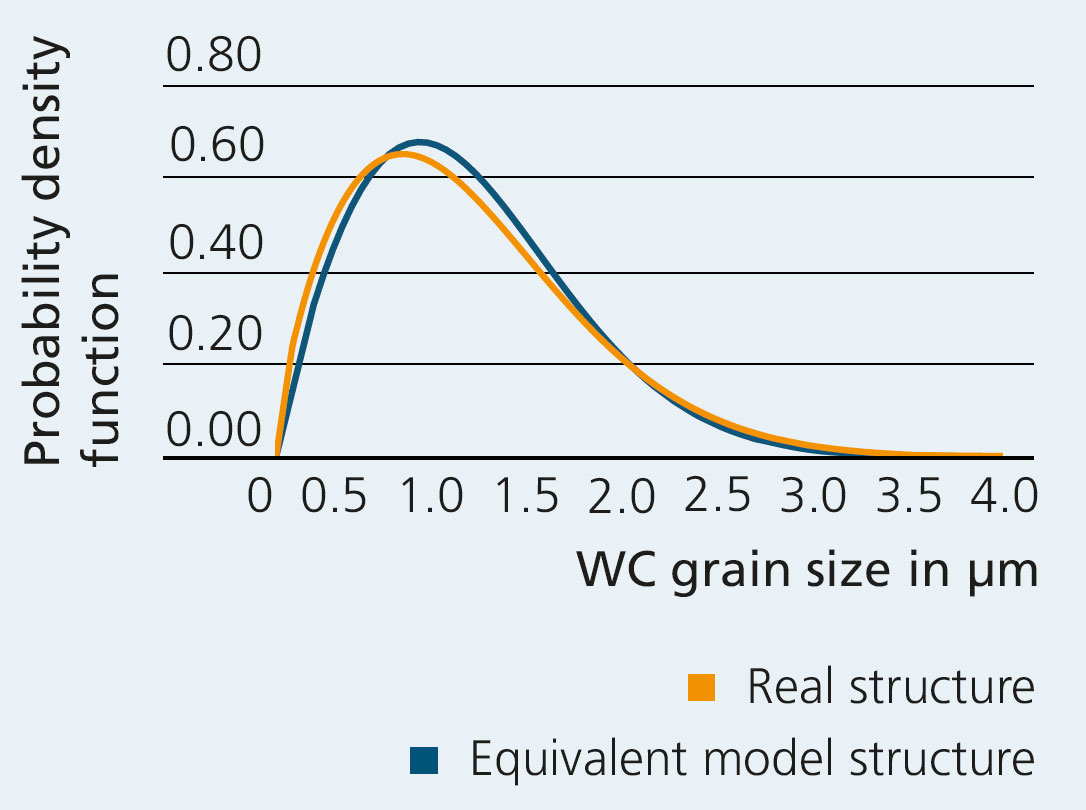

Although the fundamental relationships between microstructure and hardmetal composition are known for technically relevant properties, such as thermal conductivity, from empirical investigations of WC-Co hardmetals, making model-based predictions in order to tailor properties specifically remains highly desirable. A particular challenge consists in the strong influence of intra- and interparticle interface properties. These cannot be described satisfactorily by conventional state-of-the-art models. Modern methods of structurally detailed numerical modeling are an efficient alternative, in which a voxel-based, synthetically produced 3D geometrical model of the microstructure is used as the basis for analyzing the correlations between microstructure and properties and predict properties or specifically design the microstructure.

Fraunhofer IKTS has developed a workflow for such an analysis platform by connecting commercial, open-source and internally developed modeling tools (GeoDict, ANSYS, CCBuilder, FiPy, Mathematica) and tested and validated it by applying it to the example of thermal conductivity of WC-Co composites. Particular attention was paid to the specific shape of the interface description, which avoids the misrepresentation of the bulk volume fractions that often occurs when using voxel models. Extensive experimental data from qualitative microstructure analysis and thermal conductivity measurements was used for comparison to demonstrate that a very good agreement between models and experiments could be achieved with the new methodology. The accuracy of the results obtained exceeded the previous empirical model description significantly.

The prototypical application of this method can serve as a functional template for a microstructure-model-based property design for this material type. The general workflow developed for voxel-based synthetic microstructure analy-sis is also suitable for other material groups (composites, cellular materials) and properties (electrical, material transport, mechanical).

Supported by