Design, manufacture, and reliability assessment of ceramic springs

Current research

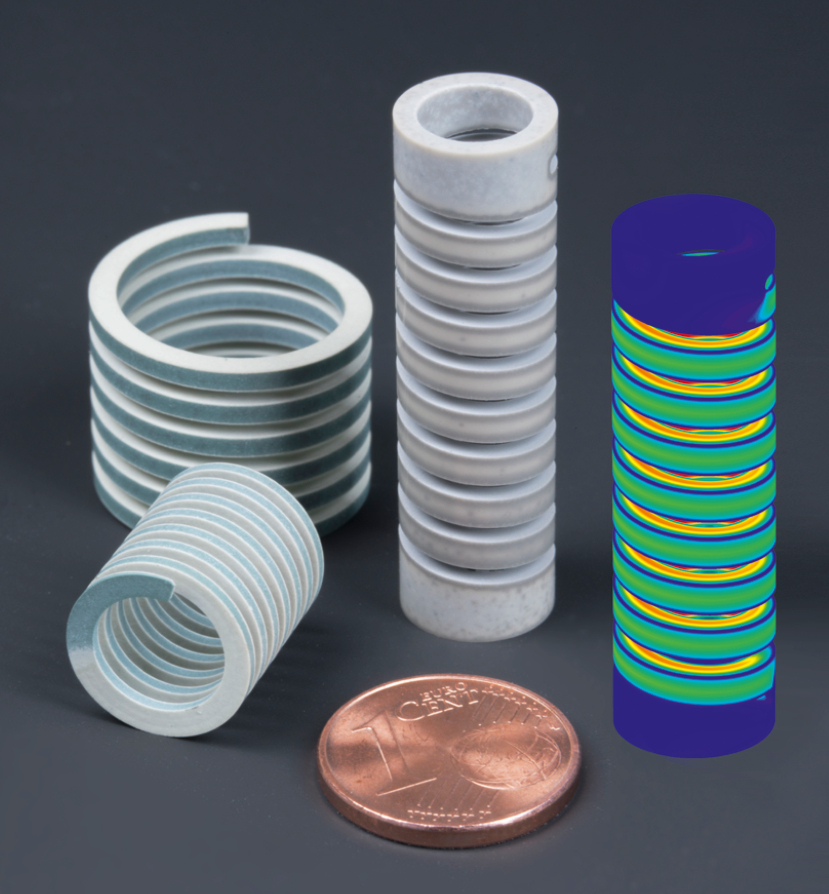

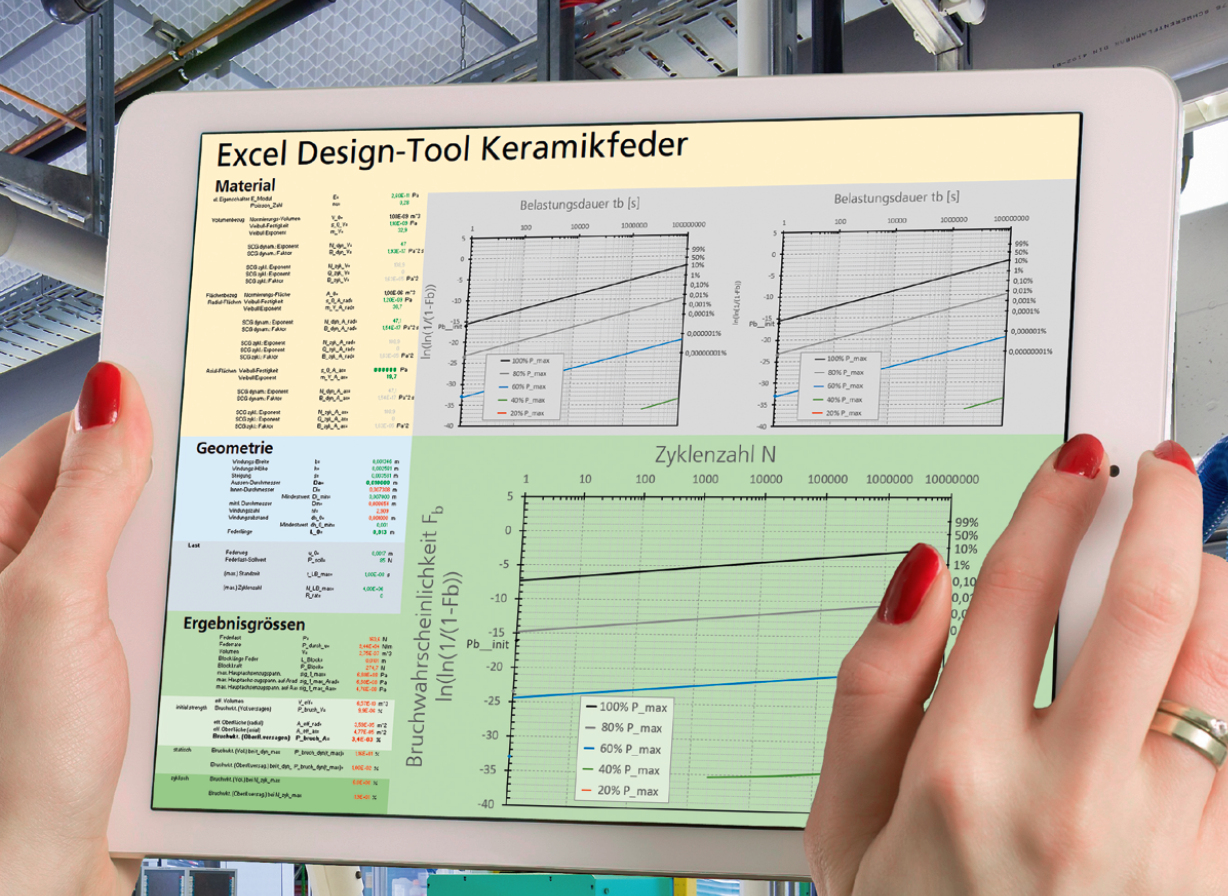

Continuous progress in ceramic technology and materials provides opportunities for the manufacturing of ceramic spring elements, such as compression springs or disc springs. Compared to standard spring materials, excellent thermal, chemical, and tribological durability and the amagnetic characteristics of the ceramic material offer promising potential for specific high-load applications, such as in medical technologies, high-temperature plants, or in chemically aggressive media. However, the current lack of experience in design, manufacturing, and use has so far effectively been a barrier for the more widespread use of ceramic spring elements. Due to manufacturing-related design adaptations (rectangular material cross section) and brittle material characteristics, standardized design procedures used for metallic springs cannot be adopted for ceramic compression springs. New design approaches need to be established, for instance for the load support at the spring ends. As part of the AiF-funded project EndurSpring (IGF project no.: 19125 BG), extensive experimental and theoretical investigations on ceramic compression springs (Fraunhofer IKTS) and disc springs (Fraunhofer IWM) were carried out in cooperation with the Verband der Deutschen Federnindustrie e. V. (the Association of German Spring Industry). This work involved developing and verifying design tools, optimizing material and technology, devising methods for testing components and materials under operating conditions, and manufacturing prototypes. A particular challenge with regard to the design of ceramic components is the requirement to apply statistical approaches (Weibull statistics) and consider defect evolution (subcritical crack growth, “SCG”) in order to estimate failure probability and lifetime. An essential factor in the analysis is the experimental characterization of the needed Weibull- and SCG parameters, which have to be obtained from elaborate statistical ex perimental test campaigns under near-operational conditions. At Fraunhofer IKTS, the favored spring material variants (Si3N4, ZrO2) were experimentally characterized under stationary, dynamic, and cyclical loads, at room temperature and at 1000 °C and for a practical range of different machining quality levels of the ceramic material (green state milled, white processed and polished), using a four-point bending test. Based on the real data sets thus obtained, design tools were developed for the initial dimensioning (Excel-based) and fine dimensioning (FEM-based) of ceramic compression springs; these tools were verified according to the methodology of statistical reliability evaluation. The experience and competence in statistical reliability validation enhanced through this specific work can also be used for the design of other ceramic components and therefore represent a valuable extension of the methodological portfolio of IKTS.

Supported by